The A213 T9 High Frequency Welded Fin Tube is a specialized component designed for high-efficiency heat transfer in demanding industrial applications. Below is a detailed breakdown of its features and characteristics:

Material Specification:

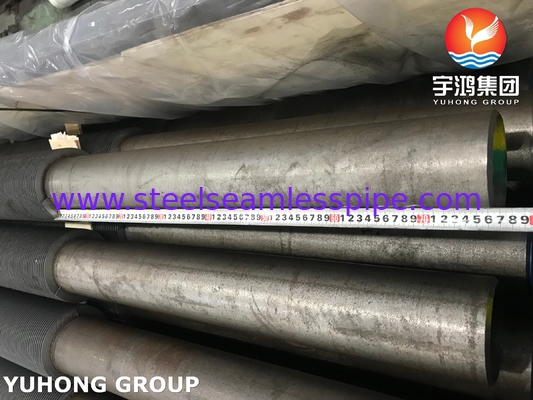

Base Tube: Manufactured from ASTM A213 T9 steel, a chromium-molybdenum (9Cr-1Mo) alloy. This material offers excellent high-temperature strength, oxidation resistance, and corrosion resistance, particularly in sulfur-bearing environments.

Fins: Typically made from carbon steel, stainless steel, or a compatible alloy, welded to the base tube.

Manufacturing Process:

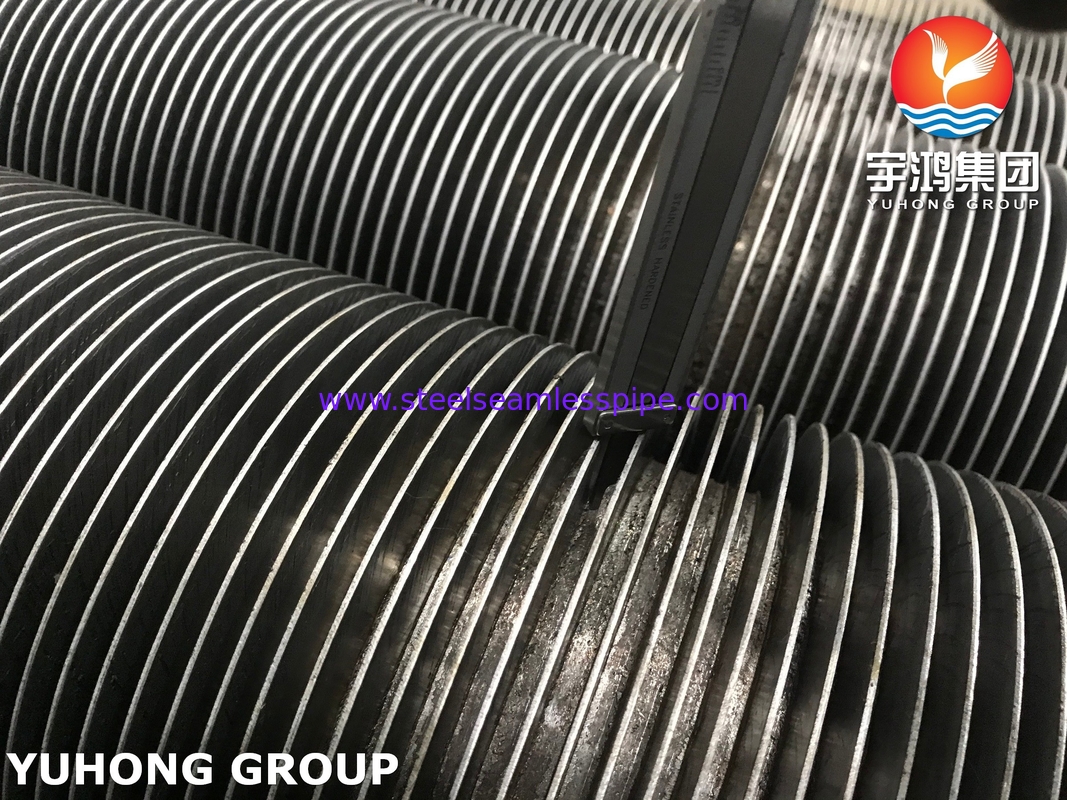

High Frequency Welding (HFW): Fins are bonded to the base tube using a high-frequency electrical current. This process ensures a strong, continuous weld with minimal thermal distortion, preserving the base material’s mechanical properties.

Structure:

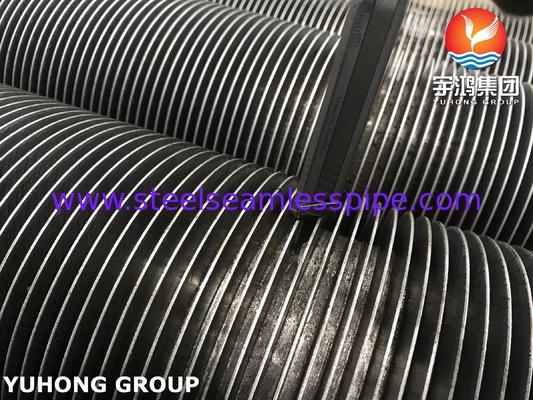

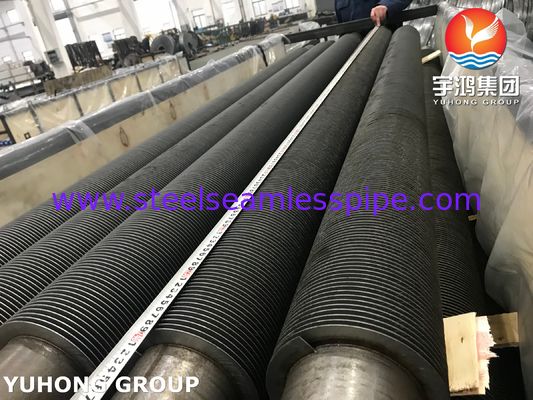

Finned Design: Helical or longitudinal fins are welded to the outer surface of the tube, significantly increasing the heat transfer surface area.

Seamless Integration: The HFW process creates a metallurgical bond between the fin and tube, enhancing durability and thermal conductivity.

Key Properties:

High-Temperature Performance: Suitable for operating temperatures up to ~600°C (1,112°F), ideal for boilers, superheaters, and heat recovery systems.

Corrosion/Oxidation Resistance: Chromium content (9%) provides resistance to oxidation and sulfidation, while molybdenum improves creep strength.

Thermal Efficiency: The finned structure maximizes heat exchange in gas-to-liquid or gas-to-steam applications.

Applications:

Power Generation: Boilers, superheaters, and economizers in coal-fired or biomass plants.

Petrochemical Industry: Heat exchangers, reformers, and furnaces in refineries.

Waste Heat Recovery: Systems requiring efficient heat transfer from exhaust gases.

Advantages:

Robust Bond: HFW ensures fins remain securely attached under thermal cycling and mechanical stress.

Customization: Available in varying diameters, fin heights, and pitches to optimize performance for specific applications.

Cost-Effectiveness: Enhanced heat transfer efficiency reduces equipment size and energy consumption.

Summary: The A213 T9 HFW Fin Tube combines the high-temperature resilience of chromium-molybdenum steel with the efficiency of high-frequency welded fins, making it a critical component in industries requiring reliable heat transfer under extreme conditions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!