ASTM A312 TP304H Serrated Fin Tube Comprehensive Overview

Material Specification (ASTM A312 TP304H):

ASTM A312: Standard for seamless/welded austenitic stainless steel pipes used in high-temperature and corrosive environments.

TP304H: A grade within A312, denoting "Type 304 High Carbon." Composition includes 18% Cr, 8% Ni, and 0.04–0.10% C. The elevated carbon enhances high-temperature creep resistance, ideal for applications above 525°C.

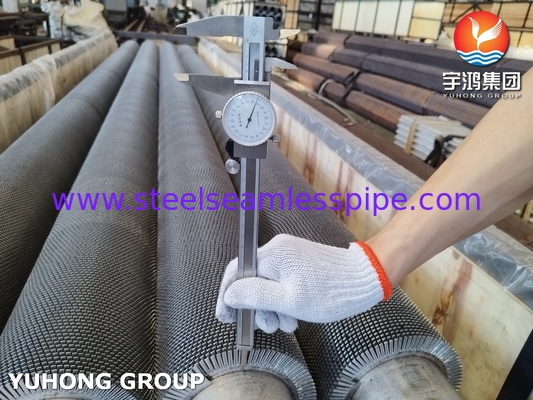

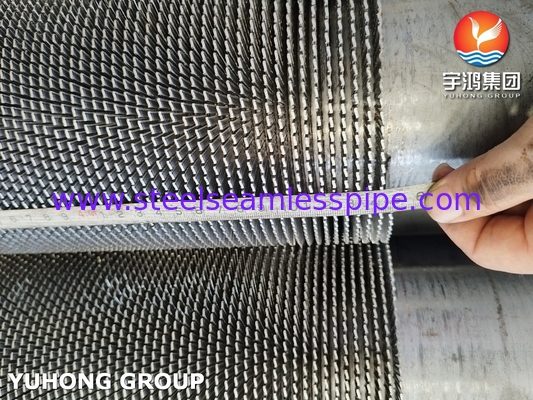

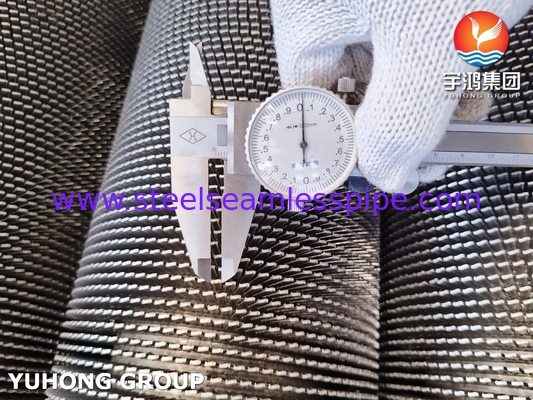

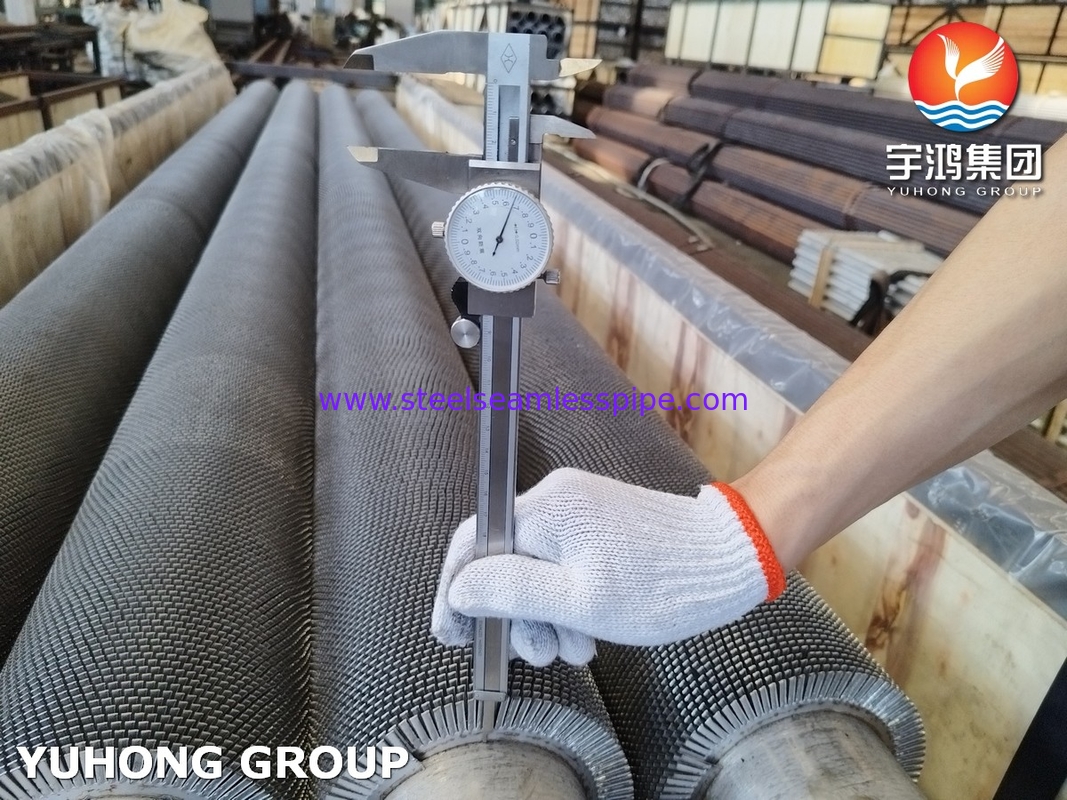

Design Features (Serrated Fin Tube):

Fin Structure: Serrated (notched) fins increase surface area and disrupt fluid boundary layers, boosting turbulence and heat transfer efficiency compared to smooth fins.

Manufacturing: Fins are typically welded, extruded, or machined onto the base tube, with serrations formed during or post-fin attachment.

Applications:

Common in industries requiring efficient heat exchange under harsh conditions: power generation (boilers, superheaters), petrochemical plants, refineries, and HVAC systems.

Suitable for high-temperature services like steam generation, exhaust gas systems, and heat recovery units.

Advantages:

Enhanced Heat Transfer: Serrations improve thermal performance by up to 30% over plain fins.

Durability: TP304H's corrosion resistance and high-temperature strength ensure longevity in aggressive environments.

Reduced Fouling: Turbulence from serrations may mitigate particulate deposition.

Considerations:

Pressure Drop: Increased turbulence can elevate system pressure loss, impacting pumping costs.

Cost: Higher material and manufacturing expenses compared to non-serrated or lower-grade tubes.

Maintenance: Regular inspections for fin integrity, corrosion, and blockages are essential.

Installation & Compatibility:

Compatible with welding and standard fittings. Ensure compatibility with fluid chemistry (e.g., chloride exposure risks for 304H).

Design should account for thermal expansion and mechanical stress to prevent fin detachment.

Conclusion: ASTM A312 TP304H Serrated Fin Tubes are optimized for high-efficiency heat transfer in demanding settings, balancing performance gains with operational costs. Selection should prioritize environment, thermal requirements, and lifecycle maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!