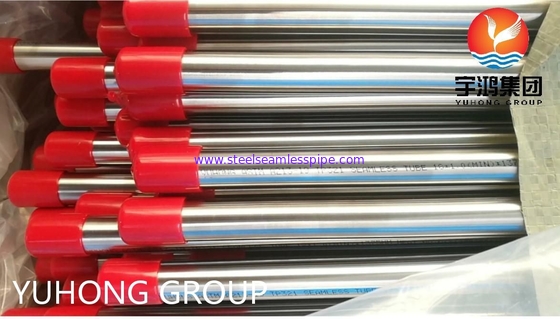

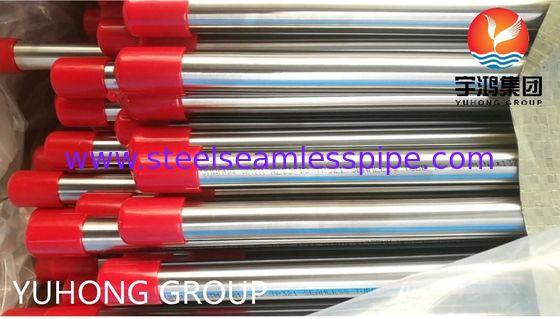

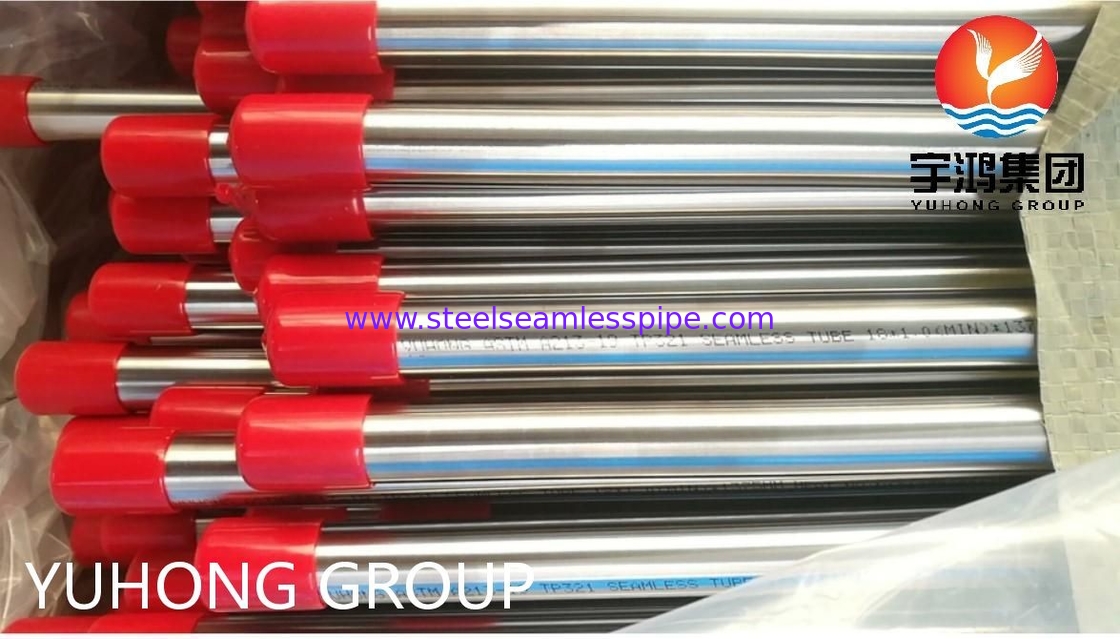

ASME SA213 TP321 Stainless Steel Seamless Polished Tube

Yuhong Special Steel has over 25 years of experience manufacturing austenitic stainless steel and nickel alloy seamless and welded pipes, with annual sales exceeding 80,000 tons. Our products serve customers in more than 45 countries worldwide including the USA, Canada, UK, Germany, Italy, Chile, Colombia, Saudi Arabia, South Korea, Singapore, Australia, Poland, and France.

Standard Specifications

- ASTM A213/A213M-11a: Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater, and Heat Exchanger Tubes

- ASTM A269-10: General Purpose Seamless and Welded Austenitic Stainless Steel Pipe

- ASTM A312/A312M-12: Seamless, Welded, and Recold-Worked Austenitic Stainless Steel Pipe

- ASTM A511/A511M-12: Seamless Stainless Steel Mechanical Tubing

- ASTM A789/A789M-10a: General Purpose Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

- ASTM A790/A790M-11: Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

- DIN 17456-2010: Seamless round stainless steel tubes for general purpose

- DIN 17458-2010: Seamless round austenitic stainless steel tubes

- EN10216-5 CT 1/2: Stainless Steel Seamless Pipe

- GOST 9941-81: Seamless cold-worked and warm-worked tubes made of corrosion-resistant steel

- Other standards including BS and JIS available upon request

Product Features

The addition of titanium in ASTM A213 TP321 pipes provides exceptional corrosion resistance and reduces the risk of intergranular corrosion common in high-carbon steels. These stainless steel seamless tubes offer extended service life at high temperatures, making them ideal for heat exchangers, superheaters, boilers, and condensers. Available in various sizes and types including easy-to-install stainless steel hoses, our TP321 tubing is manufactured with high precision for demanding industrial applications.

Chemical Composition - TP321 (S32100)

| Element |

Content (%) |

| Carbon |

0.08 |

| Manganese |

2.00 |

| Phosphorus |

0.045 |

| Sulfur |

0.030 |

| Silicon |

1.00 |

| Chromium |

17.0-19.0 |

| Nickel |

9.0-12.0 |

| Molybdenum |

2.00-3.00 |

| Titanium |

5(C + N)-0.70 |

Available Material Grades

American Standard: TP304, TP304L, TP304H, TP304N, TP310S, TP316, TP316L, TP316Ti, TP316H, TP317, TP317L, TP321, TP321H, TP347, TP347H, 904L, S31803, S32101, S32205, S32304, S32750, S32760, TP405, TP409, TP410, TP430, TP439

Mechanical Properties

| Property |

Imperial (Psi) |

Metric (MPa) |

| Tensile Strength |

75,000 |

515 |

| Yield Strength (0.2% Offset) |

30,000 |

205 |

| Elongation |

35% |

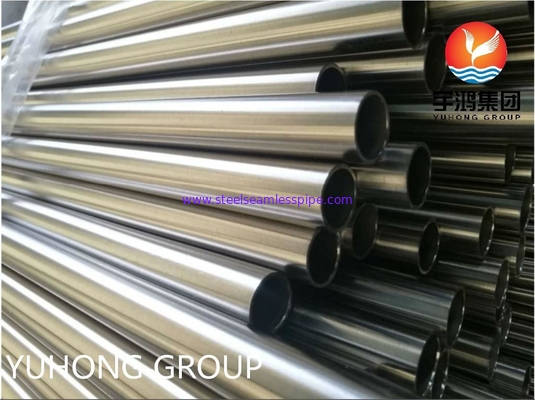

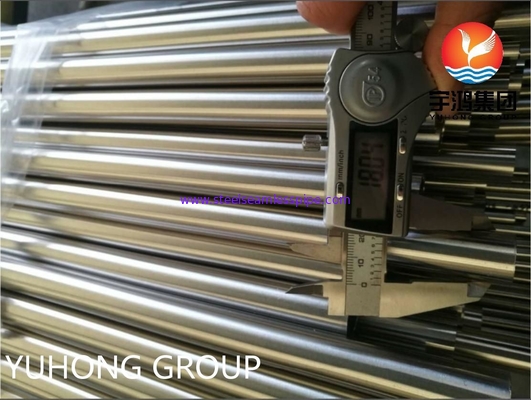

Size Range

| Production |

Outside Diameter |

Wall Thickness |

| Seamless Pipe |

6.00mm - 830mm |

0.5mm - 48mm |

Standard tubing sizes range from 1/8 inch (3.2 mm) inner diameter to 5 inches (127 mm) outer diameter, with wall thickness from 0.015 to 0.500 inches (0.4 to 12.7 mm). Custom diameters can be manufactured to meet specific requirements while maintaining compliance with specification standards.

Applications

- Food processing equipment (beer brewing, milk processing, wine making)

- Kitchen benches, sinks, and appliances

- Building paneling, railings, and decorative elements

- Chemical containers and transportation vessels

- Heat exchangers and boiler superheaters

- Woven or welded screens for mining, quarrying, and water filtration

- Threaded fasteners and springs

- Various industrial applications requiring corrosion resistance

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!