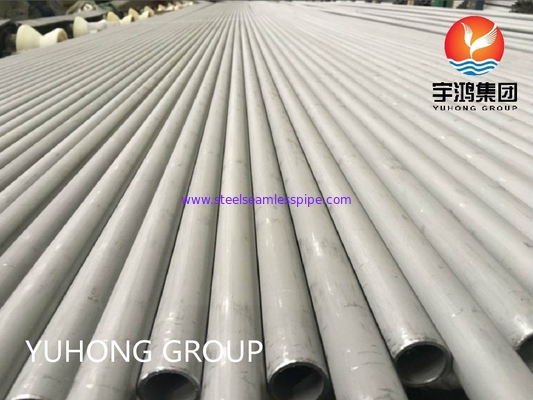

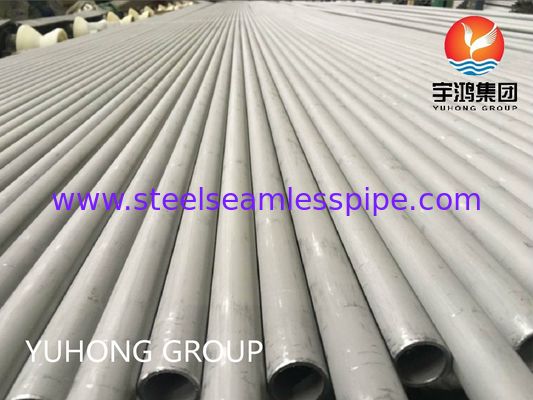

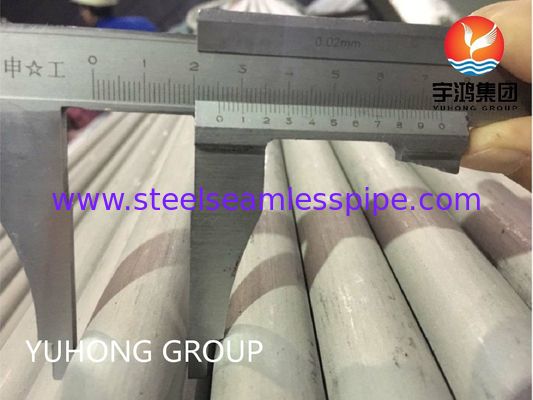

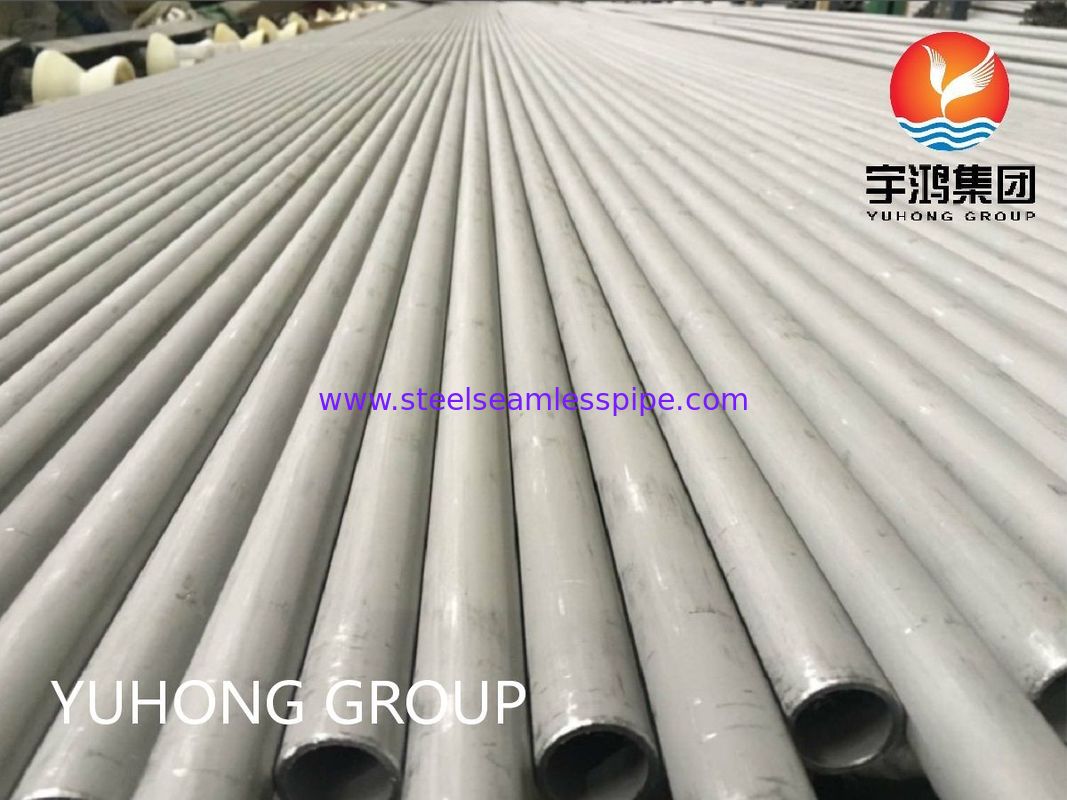

ASTM A213 TP321 Stainless Steel Seamless Tube

Yuhong Special Steel has over 25 years of experience manufacturing seamless welded pipes and tubes from austenitic stainless steel and nickel alloy steel (Hastelloy, Monel, Inconel). With annual sales exceeding 80,000 tons, we serve customers in over 55 countries worldwide including the USA, Canada, UK, Germany, Italy, Chile, Colombia, Saudi Arabia, South Korea, Singapore, Australia, Poland, and France.

Stainless Steel 321 is a stabilized austenitic 18/8 steel (based on grade 304) with titanium additions. This stabilization prevents susceptibility to intergranular corrosion after heating in the carbide precipitation range of 425-850°C. SS 321 is ideal for applications up to approximately 900°C, offering high strength, scaling resistance, phase stability, and subsequent water corrosion resistance. SS 321H provides enhanced high-temperature strength with a higher carbon content.

Specifications

| Standard |

SS 321 |

SS 321H |

| AISI |

321 |

321H |

| UNS |

S32100 |

S32109 |

| Werkstoff Nr. |

1.4541 |

1.4878 |

Mechanical & Physical Properties

Density: 8.0 g/cm³

Melting Point: 1454°C (2650°F)

Tensile Strength: 75,000 Psi / 515 MPa

Yield Strength (0.2% Offset): 30,000 Psi / 205 MPa

Elongation: 35%

Chemical Composition

| Element |

SS 321 |

SS 321H |

| Ni |

9 - 12 |

9 - 12 |

| Cr |

17 - 19 |

17 - 19 |

| C |

0.08 max |

0.04 - 0.10 |

| N |

0.10 max |

|

| Fe |

Balance |

| Mn |

2 max |

2 max |

| Si |

0.75 max |

0.75 max |

| S |

0.03 max |

0.03 max |

| P |

0.045 max |

0.045 max |

| Ti |

5xC min, 0.60% max |

4xC min, 0.60% max |

Material Characteristics

Alloys 321 (S32100) and 347 (S34700) are stabilized stainless steels offering excellent resistance to intergranular corrosion after exposure to the chromium carbide precipitation temperature range of 800 to 1500°F (427 to 816°C). Alloy 321 achieves stabilization through titanium additions, while Alloy 347 uses niobium and tantalum.

While Alloys 321 and 347 remain suitable for long-term use in the 800 to 1500°F temperature range, Alloy 304L has largely replaced these stabilized grades for applications involving only welding or short-term heating.

Alloy 321 and 347 stainless steels provide superior mechanical properties for high-temperature applications, offering higher creep and stress rupture properties than Alloy 304, particularly compared to Alloy 304L. This results in higher allowable stresses for code applications such as ASME boiler and pressure vessel standards. Both alloys have maximum service temperatures of 1500°F (816°C), while Alloy 304L is limited to 800°F (426°C).

Corrosion Resistance

General Corrosion

Alloys 321 and 347 provide general corrosion resistance comparable to Alloy 304. Prolonged heating in the carbide precipitation range may affect corrosion resistance in severely corrosive environments.

In most environments, both alloys demonstrate similar performance; however, annealed Alloy 321 shows slightly lower resistance to general corrosion than annealed Alloy 347 in strongly oxidizing conditions. Therefore, Alloy 347 is preferred for water and other low-temperature applications. Alloy 321 experiences more significant degradation in corrosion resistance than Alloy 347 when exposed to temperatures between 800°F to 1500°F (427°C to 816°C).

Physical Properties

The physical characteristics of Alloys 321 and 347 are nearly identical and can be considered equivalent for practical applications. When properly annealed, these alloys consist primarily of austenite and titanium or niobium carbides, with possible small amounts of ferrite. Sigma phase may form during prolonged exposure to temperatures between 1000°F to 1500°F (593°C to 816°C).

These stabilized stainless steels cannot be hardened by heat treatment. While thermal conductivity is a factor in heat transfer, stainless steel's ability to maintain clean surfaces typically results in comparable or better performance than metals with higher thermal conductivity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!