|

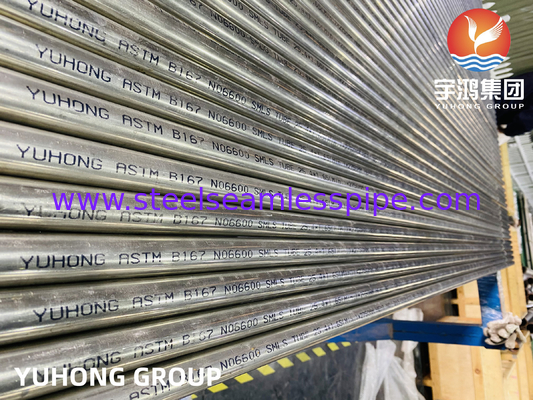

ALLOY 600 (75 Ni/16 Cr)

|

Dimension (mm)

|

|

cold drawn, seamless, annealed

|

1.5 x 0.25

|

|

cold drawn, seamless, annealed

|

2.0 x 0.5

|

|

seamless

|

3.0 x 0.4

|

|

cold drawn, annealed, seamless

|

3.0 x 0.5

|

|

cold drawn, annealed, seamless

|

4.0 x 0.25

|

|

cold drawn, seamless, annealed

|

4.0 x 0.5

|

|

seamless, annealed

|

4.0 x 1.0

|

|

seamless, cold drawn

|

4.5 x 0.5

|

|

cold drawn, seamless, annealed

|

5.0 x 0.5

|

|

annealed, seamless

|

5.0 x 1.0

|

|

seamless, hard drawn

|

5.0 x 1.0

|

|

seamless, annealed

|

6.0 x 0.5

|

|

on coil, seamless, annealed

|

6.0 x 1.0

|

|

cold drawn, seamless, annealed

|

6.0 x 1.0

|

|

hard drawn, seamless

|

6.0 x 1.5

|

|

seamless, annealed

|

6.35 x 1.63 (¼" x 0.064")

|

|

seamless, seamless, annealed

|

8.0 x 1.0

|

|

cold drawn, annealed, seamless

|

10.0 x 1.0

|

|

seamless

|

10.0 x 2.0

|

|

cold drawn, annealed, pickled

|

12.7 x 1.7 (½" x 0.065")

|

|

seamless, annealed

|

13.72 x 1.65 (¼"nb Sch10s)

|

|

seamless, cold drawn, pickled, annealed

|

14.0 x 3.0

|

|

cold drawn, annealed, pickled

|

15.0 x 1.5

|

|

cold drawn, annealed

|

15.8 x 1.7 (5/8" x 0.065")

|

|

cold drawn, annealed, pickled

|

18.0 x 2.0

|

|

cold drawn, pickled, annealed

|

21.34 x 1.65 (½"nb Sch5)

|

|

cold drawn, pickled, annealed

|

21.34 x 2.11 (½"nb Sch10s)

|

|

cold drawn, annealed, pickled

|

21.34 x 2.77 (½"nb sch40s)

|

|

cold drawn, annealed, pickled, seamless

|

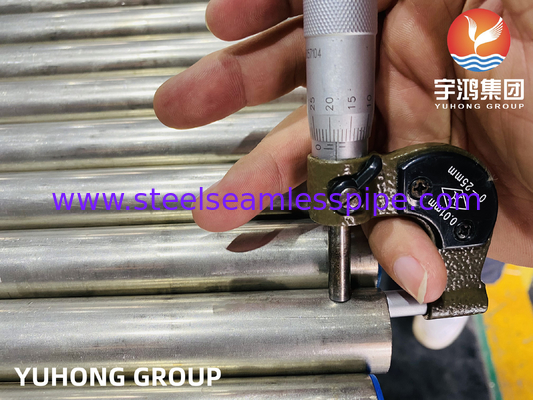

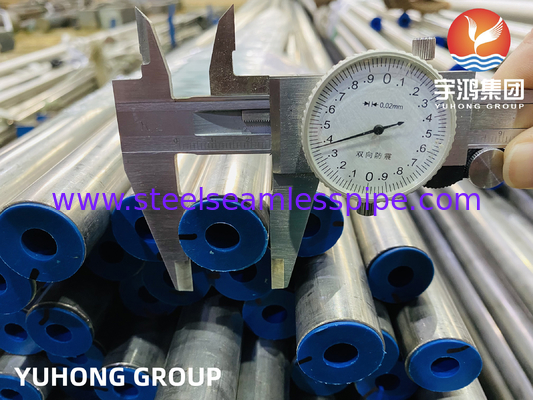

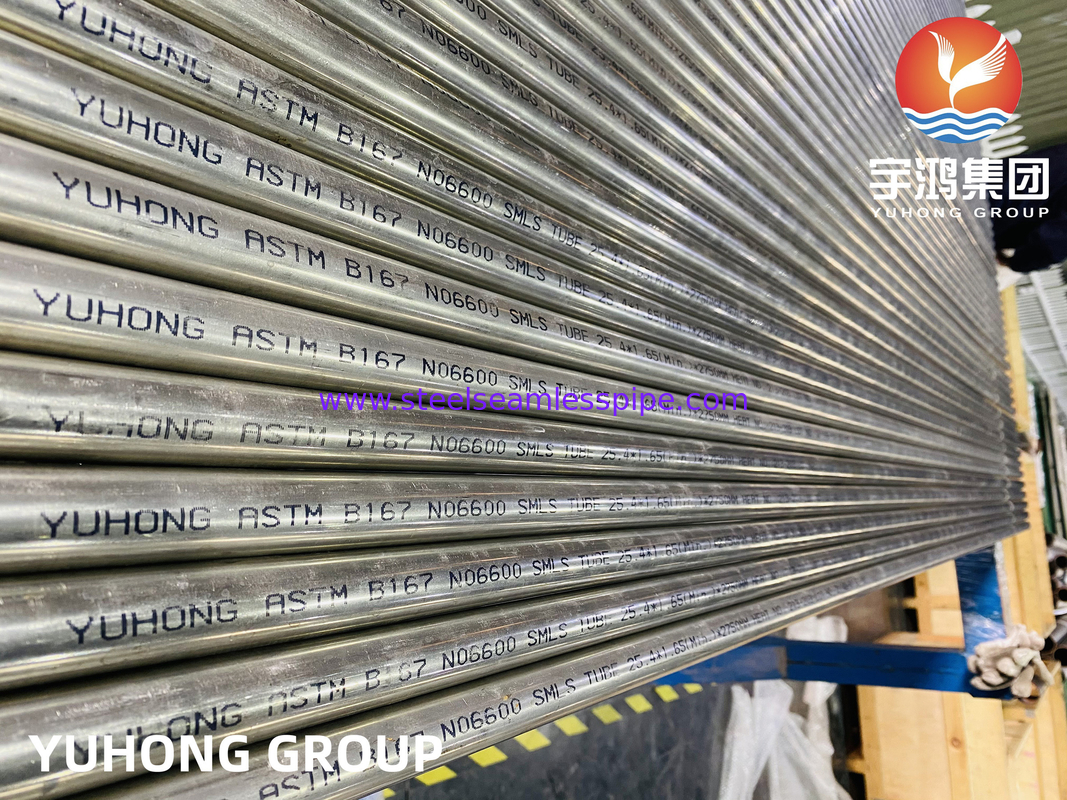

25.4 x 1.65 (1" x 0.065")

|

|

cold drawn, seamless, annealed, pickled

|

26.67 x 2.11 (¾"nb Sch10s)

|

|

cold drawn, annealed, pickled

|

26.67 x 2.87 (¾"nb sch40s)

|

|

cold drawn, pickled, annealed

|

26.67 x 3.91 (¾"nb Sch80s)

|

|

cold drawn, annealed, pickled

|

30.0 x 2.5

|

|

cold drawn, seamless, pickled, annealed

|

33.4 x 2.77 (1"nb Sch10s)

|

|

cold drawn, seamless, annealed, pickled

|

33.4 x 3.38 (1"nb Sch40s)

|

|

cold drawn, pickled, annealed

|

33.4 x 4.55 (1"nb Sch80s)

|

|

cold drawn, seamless, pickled, annealed

|

42.16 x 1.65 (1¼"nb sch5s)

|

|

cold drawn, seamless, annealed, pickled

|

42.16 x 3.56 (1¼"nb Sch40s)

|

|

cold finished, seamless, annealed

|

48.26 x 2.77 (1½"nb Sch10s)

|

|

cold finished, seamless, annealed

|

48.26 x 3.68 (1½"nb Sch40s)

|

|

seamless, cold drawn, annealed, pickled

|

53.5 x 3.0

|

|

cold drawn, pickled, annealed

|

60.33 x 2.77 (2"nb sch10s)

|

|

cold drawn, pickled, annealed

|

60.33 x 3.91 (2"nb sch40s)

|

|

seamless, cold drawn, pickled, annealed

|

66.0 x 4.0

|

|

seamless, cold drawn, pickled, annealed

|

76.2 x 3.3

|

|

seamless, cold drawn, pickled, annealed

|

88.9 x 3.05 (3"nb sch10s)

|

|

seamless, cold drawn, pickled, annealed

|

88.9 x 5.49 (3"nb sch40s)

|

|

cold drawn, pickled, annealed

|

114.3 x 3.05 (4"nb sch10s)

|

|

cold drawn, pickled, annealed

|

114.3 x 6.02 (4"nb sch40s)

|

|

extruded, pickled, annealed

|

141.3 x 6.55 (5"nb sch40s)

|

|

extruded, pickled, annealed

|

153.0 x 6.5

|

|

seamless, extruded, pickled, annealed

|

168.28 x 7.11 (6"nb sch40s)

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!