1.Base Tube Material: A106 Gr.B

Standard: ASTM A106 / ASME SA106.

Type: Seamless carbon steel pipe.

Grade: B (Intermediate tensile/yield strength).

Properties:

- Good high-temperature strength (up to ~450°C / 840°F).

- Good weldability and formability.

- Cost-effective.

- Limitation: Susceptible to corrosion (rusting) and oxidation (scaling) at high temperatures without protection; not suitable for corrosive environments unless clad or coated.

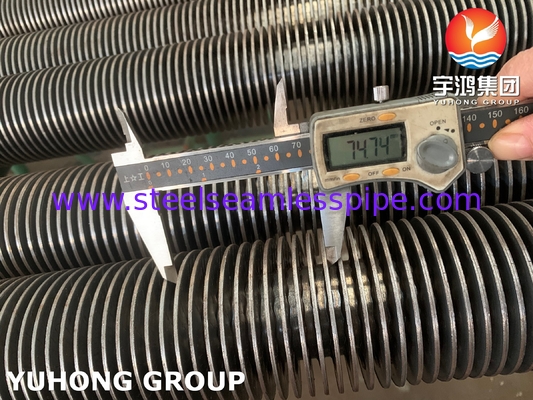

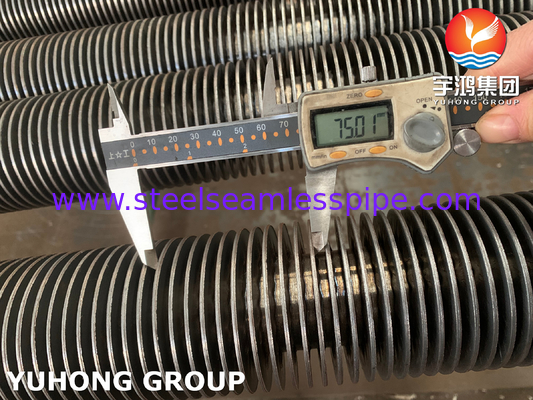

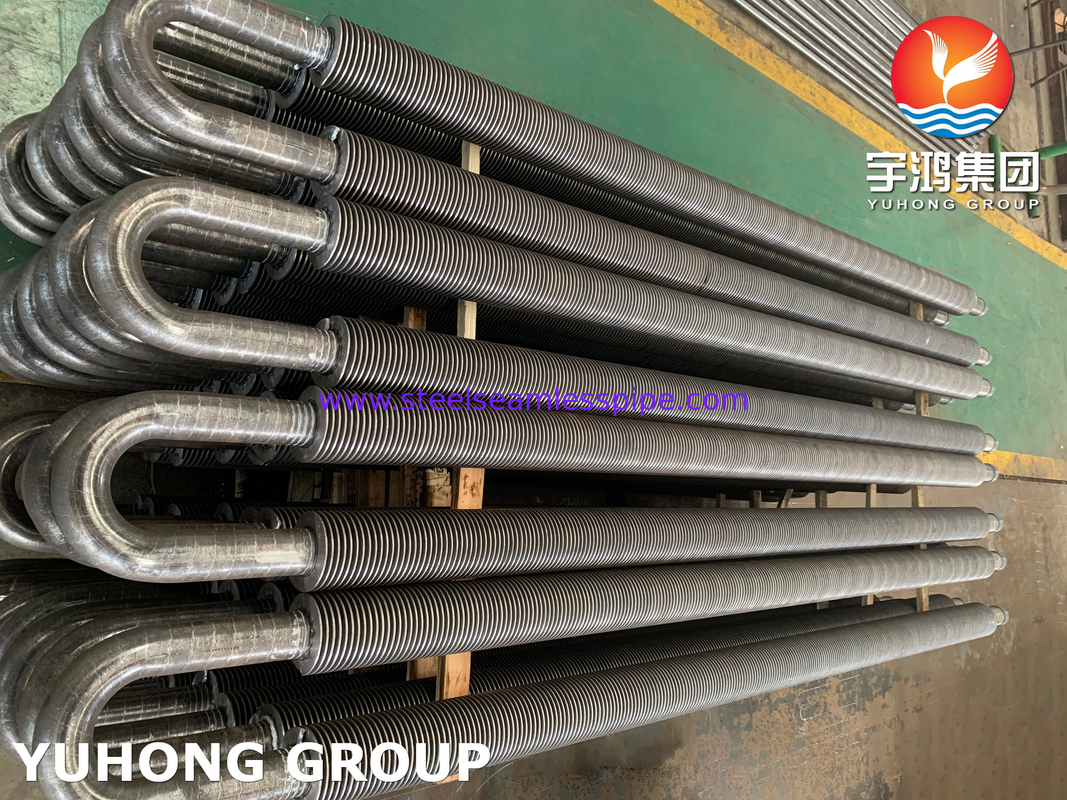

2. Fin Type: Solid Fin

Construction: Fins are made from solid strips of material (typically carbon steel or sometimes stainless steel for corrosion resistance).

Attachment: The fins are continuously welded (usually resistance welded, LFW, or HFW) along their base to the outside surface of the base tube. This creates a strong, metallurgical bond.

Advantages:

Excellent Heat Transfer: Direct metal-to-metal contact provides very low thermal resistance.

High Mechanical Strength & Durability: Resistant to vibration, erosion, and physical damage.

Good for High Temperatures: The welded joint maintains integrity at elevated temperatures.

Cleanable: Smooth surfaces allow for easier cleaning/sweeping compared to embedded fins.

Disadvantages:

Higher cost than extruded or embedded fins.

Slightly higher pressure drop than lower-profile fins.

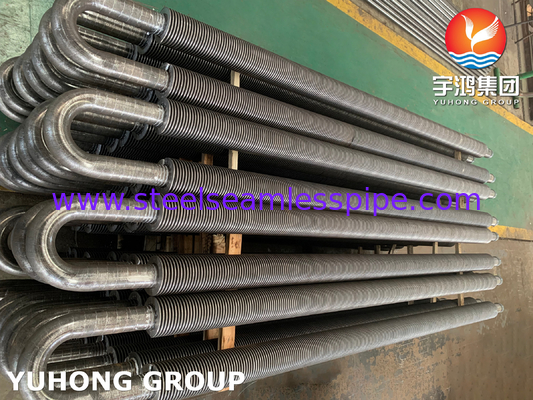

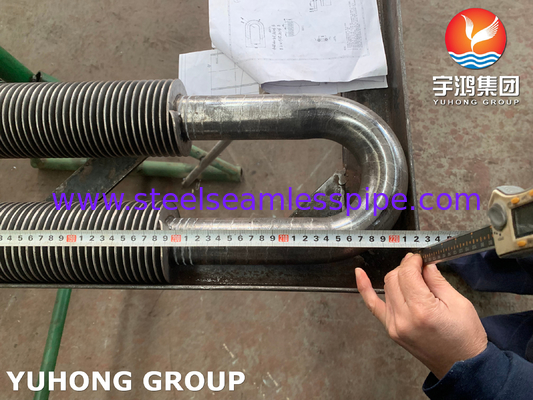

3. Overall Tube Configuration: U-Type

Shape: The finned tube is bent into a tight "U" shape (180-degree bend).

Purpose:

Thermal Expansion: Allows the tube bundle to expand and contract freely within the shell of a heat exchanger without inducing excessive stress on the tubesheets or tubes.

Bundle Removal: Facilitates pulling the entire tube bundle out of the shell for inspection, cleaning, or maintenance.

Single Tubesheet: Only requires one tubesheet at the straight end, simplifying the header/channel box design at that end.

Construction: The bending process occurs after the fins are attached. Careful bending equipment and techniques are required to avoid damaging the fins or compromising the fin-tube bond at the bend apex.

4. Summary & Typical Applications:

An A106 Gr.B U-Type Solid Fin Tube is a robust, high-performance heat transfer element designed for demanding high-temperature applications where thermal expansion accommodation and durability are critical. Its core features are:

High-Temp Carbon Steel Base: For structural integrity under heat and pressure.

Durable Solid Welded Fins: For efficient and reliable heat transfer to air/gas.

U-Bend Configuration: For stress-free thermal expansion and easy maintenance.

Common Applications:

Heat Recovery Steam Generators (HRSGs): Economizer, evaporator, and superheater sections recovering heat from gas turbine exhaust.

Process Heaters & Furnaces: Convection sections transferring heat from flue gas to process fluid.

Waste Heat Boilers: Recovering heat from high-temperature process streams.

Air Heaters / Preheaters: Heating combustion air using exhaust flue gas.

Finned Tube Bundles in Shell & Tube Exchangers: Where gas is on the shell side and thermal expansion is significant.

Key Considerations:

Corrosion: A106 Gr.B requires protection (e.g., coatings like aluminizing, finning with stainless steel, operating in dry/non-corrosive gas) in environments with moisture, acids, or sulfur.

Oxidation: Will form scale at high temperatures; needs consideration for long-term performance.

Fin Density: The number of fins per inch/meter is chosen based on gas cleanliness (fouling potential) and required heat transfer vs. pressure drop.

Bend Radius: The tightness of the U-bend is critical and defined by the heat exchanger design and tube diameter.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!