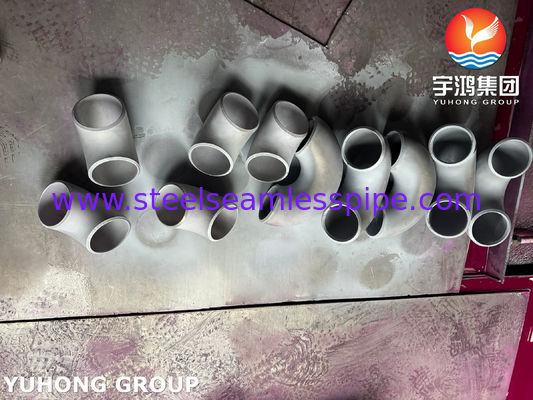

ASTM A403 WP304H Stainless Steel Fitting Short Range Elbow Buttwelded Seamless B16.9

ASTM A403 is a standard specification developed by the American Society for Testing and Materials specifically for austenitic stainless steel fittings, covering types of fittings such as elbows, tees, reducers (big and small heads), pipe caps, flanged short joints, water traps, and branch fittings. This standard provides strict requirements for the materials, manufacturing, dimensions, tolerances, testing, inspection, and marking of these fittings.

WP304H is a material grade under ASTM A403 standard, where "WP" refers to seamless or welded austenitic stainless steel fittings manufactured through forging, rolling, or extrusion processes, and requires heat treatment; "H"stands for High Carbon. Compared with ordinary 304 material, 304H has a higher carbon content and needs to be controlled within the range of 0.04-0.10% to enhance the strength and creep resistance of the material in high temperature environments.

Fitting Classes for WP Grades

|

Class

|

|

Nondestructive Examination

|

| S |

Seamless |

|

| W |

Welded |

Radiography or Ultrasonic

|

| WX |

Welded

|

|

| WU |

Welded |

|

ASTM A403 WP321H Stainless Steel Chemical Composition

|

WP

GRA.

|

UNS

GRA.

|

CHEMICAL COMPOSITION % Maximum |

| C |

MN |

P |

S |

Si |

NI |

Cr |

| WP304 |

S30400 |

0.08 |

2.0 |

0.045 |

0.030 |

1.00 |

8.0-11.0 |

18.0-20.0 |

| WP304H |

S30409 |

0.04-0.10 |

2.0 |

0.045 |

0.030 |

1.00 |

8.0-12.0 |

18.0-20.0 |

What is the difference between WP304H and WP304?

The core difference between WP304H and WP304 materials is the Carbon Content.

WP304H has a higher carbon content, which needs to be maintained in the range of 0.04% -0.10%, while WP304 has a lower carbon content, which needs to be less than or equal to 0.08%. The difference in carbon content leads to differences in the mechanical properties of WP304H and WP304, with the most significant being their stability in high temperature environments greater than or equal to 525 ° C.

The higher carbon content brings excellent creep resistance and durability to WP304H, making it more suitable for key high-temperature and high-pressure pipeline systems such as supercritical/ultra supercritical boilers in thermal power plants and high-temperature cracking units in petrochemicals. WP304 is a universal austenitic stainless steel that is more suitable for normal, low, or medium temperatures (generally below 425 ° C/800 ° F).

ASTM A403 WP304H Stainless Steel Fitting Heat Treatment

|

WP GRA.

|

Solution Anneal

Temperature, min °F [°C]B

|

|

| WP304H |

1900 [1040]

|

water or other rapid cool

|

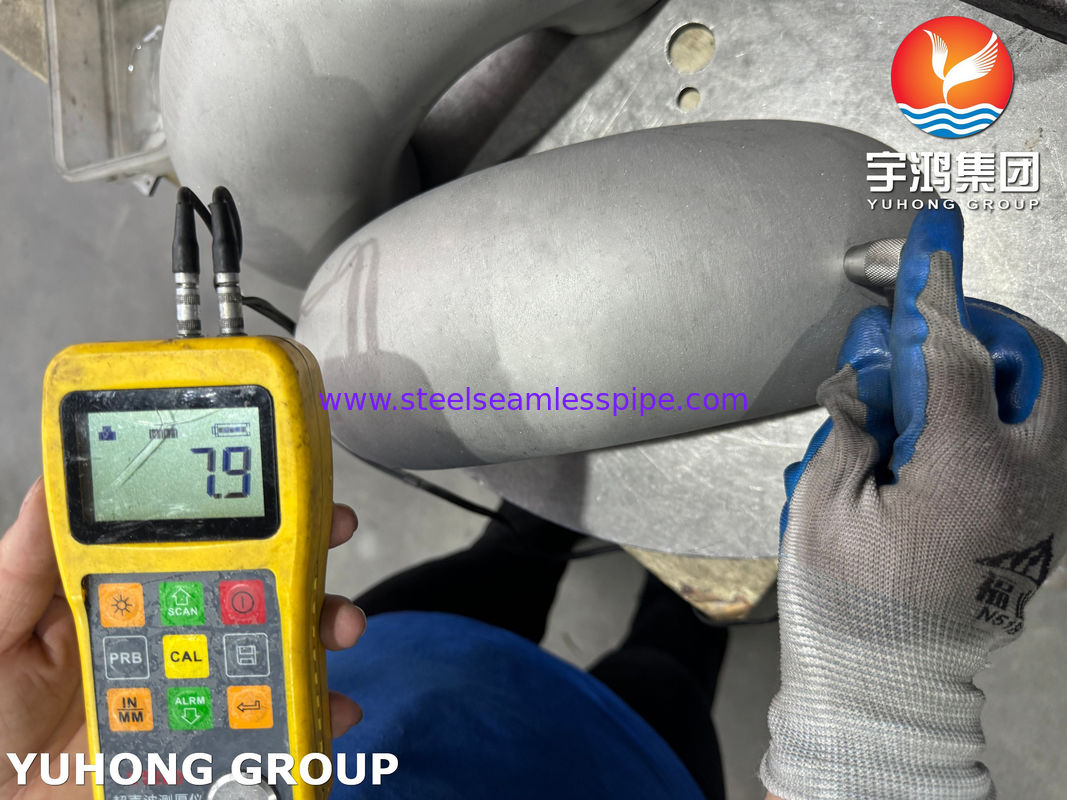

ASTM A403 WP304H Stainless Steel Fitting Tensile Requirements

|

WP GRA.

|

Yield Strength, min,

ksi [MPa]

|

Tensile Strength, min,

ksi [MPa]

|

| WP304H |

30[205] |

|

ASTM A403 WP304H Stainless Steel Fitting Application

-

Petrochemical industry: high-temperature process pipelines for high-temperature cracking units, hydroprocessing units, etc.

-

Thermal power plants: boiler superheaters, reheaters, high-temperature reheated steam pipelines, etc.

-

Chemical plant: Process pipelines involving high-temperature reactions, heating, and cooling.

-

Boiler system: hot water circulation and high-temperature steam system.

-

Other industrial pipeline systems that require high temperature strength and seamless reliability.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!