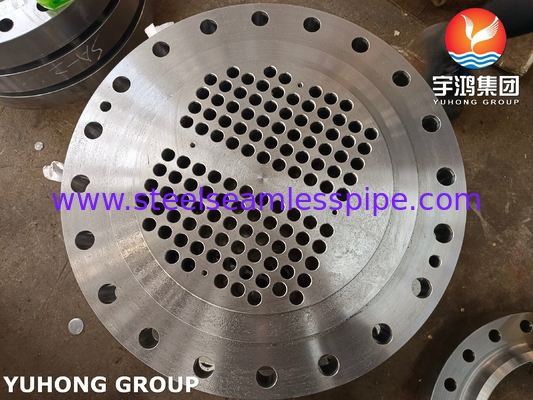

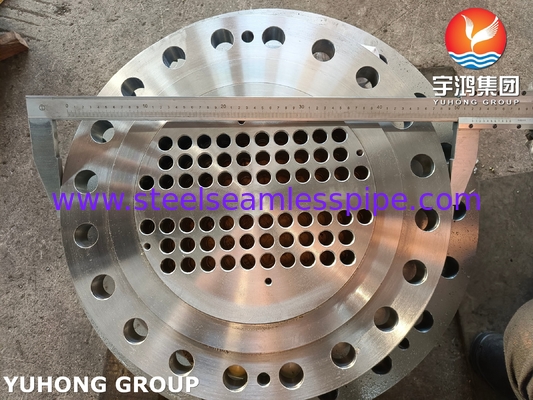

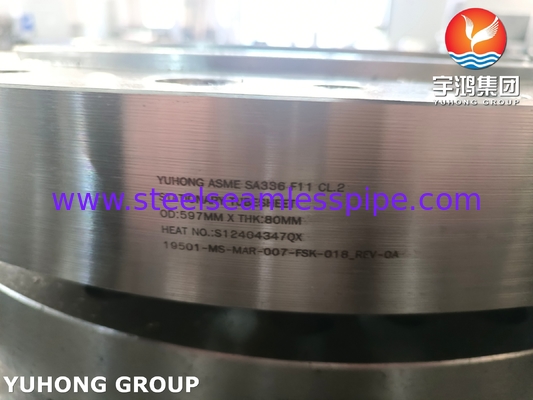

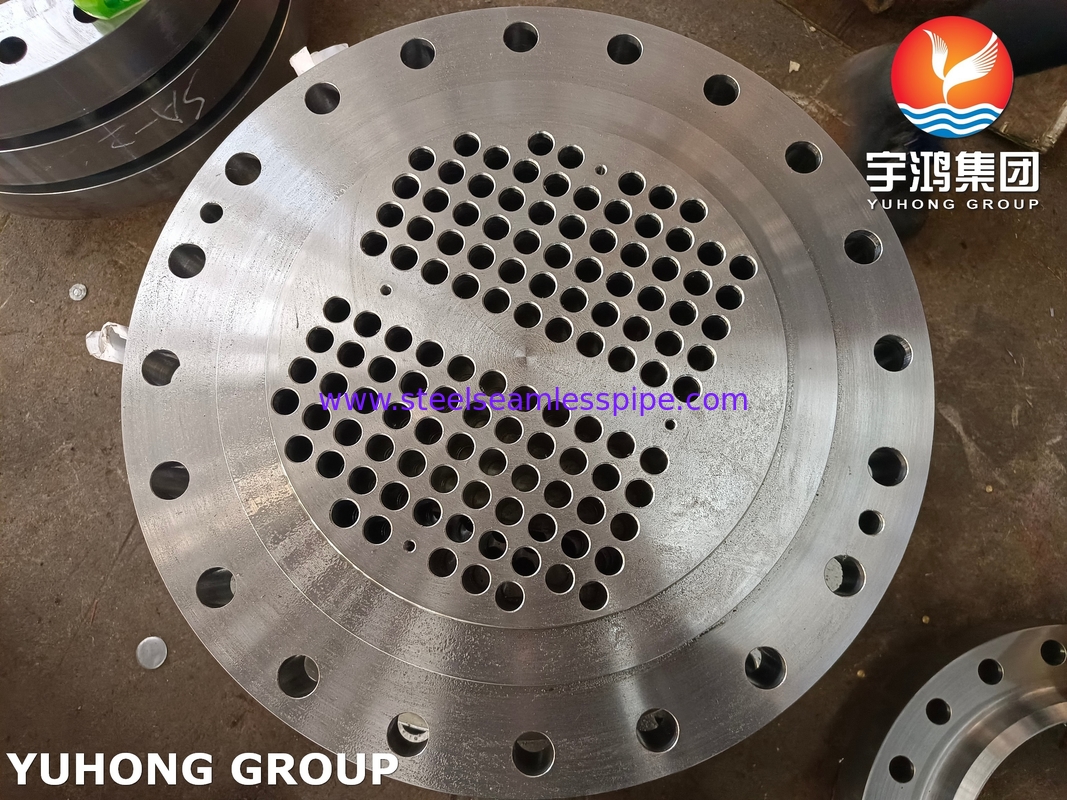

ASME SA336 F11 Class2 Alloy Steel Tubesheet For Heat Exchangers F1 F12 F22 F21 F5 F9

ASME SA336 F11 CL2 high-temperature alloy steel tubesheets are core pressure-bearing components of shell-and-tube heat exchangers designed for extreme high-temperature, high-pressure, and hydrogen-corrosive environments.

Made from chromium-molybdenum alloy steel forgings (1.0-1.5% Cr, 0.44-0.65% Mo), heat-treated to ensure high strength and toughness even at temperatures ≤595°C.

This material resists high-temperature hydrogen corrosion and is suitable for demanding applications such as hydrogenation reactors, nuclear steam generators, and thermal power plant high-pressure feedwater heaters. Compared to carbon steel tubesheets, its high-temperature strength retention is 40% higher, and controlled hardness effectively suppresses wet H₂S stress corrosion cracking.

Typical applications include refinery 15MPa-rated reaction effluent heat exchangers, thermal power plant feedwater systems subject to temperature swings exceeding 150°C, and waste heat boilers in ammonia synthesis plants.

SA336 Grade F11 Class 2 Chemical Element Content (%)

| Composition |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

| Minimum |

0.1 |

0.5 |

0.3 |

- |

- |

1 |

0.45 |

| Maximum |

0.2 |

1 |

0.8 |

0.025 |

0.025 |

1.5 |

0.65 |

SA336 Grade F11 Class 2 Mechanical Properties

|

Tensile Strength

σb

Mpa

|

Yield Point

σs

Mpa

|

Elongation or Elongation

δ

%

|

Reduction of Area

ψ

%

|

| 485~660 |

≥275 |

≥20 |

≥40 |

Application

Energy and Power Industry: Nuclear Power Secondary Circuit Steam Generators, Thermal Power High-Pressure Feedwater Heaters

Petroleum Refining and Chemical Industry: Hydrogenation Reaction Effluent Heat Exchangers, Hydrocracking/Desulfurization Units

Methanol Synthesis Tower Feed Heat Exchangers

Ethylene Cracking Quench Boilers

PTA Process Titanium Heat Exchangers

Marine Diesel Engine Charge Air Coolers

Hydrogen Energy Equipment: High-Pressure Hydrogen Heat Exchangers

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!