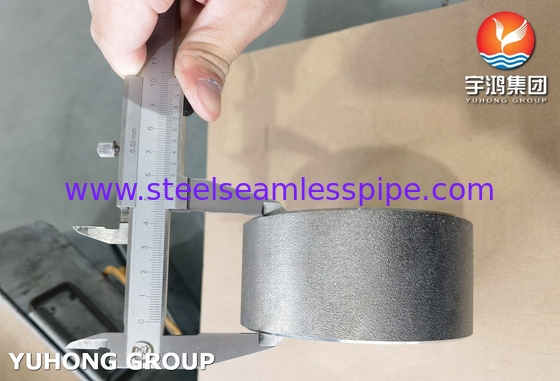

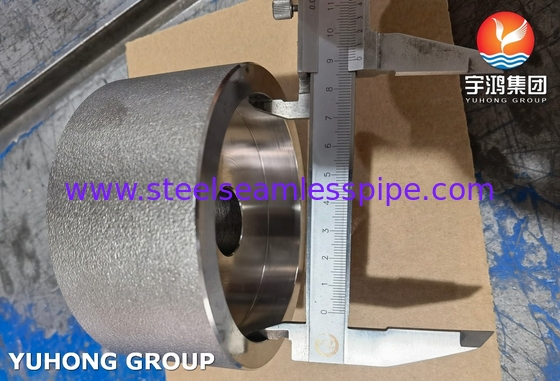

ASTM A182 F304 Stainless Steel Coupling ASME B16.11

ASTM A182 governs forged or rolled alloy and stainless steel components (flanges, fittings, valves) for high-temperature service.

ASTM A182 F304 coupling is a forged stainless steel fitting designed for durable, high-temperature, and corrosion-resistant piping connections. It adheres to strict material (ASTM A182) and dimensional (ASME B16.11) standards, making it suitable for demanding industrial applications. Proper selection requires evaluating environmental factors (e.g., chlorides), thermal conditions, and welding needs.

Grade F304 refers to 304 stainless steel, an austenitic chromium-nickel alloy with excellent corrosion resistance and high-temperature performance.Non-magnetic, good weldability, corrosion resistance in oxidizing environments, but less suitable for chloride-rich settings.

Stainless Steel ASME SA182 F304L Forged Threaded Pipe Fittings Chemical Composition

| Grade |

Mn |

Si |

Cr |

N |

P |

C |

S |

Ni |

Ti |

| SS 304 |

2.0 max |

1.0 max |

17.00 – 19.00 |

0.10 max |

0.045 max |

0.08 max |

0.030 max |

9.00 – 12.00 |

5(C+N) – 0.70 max |

| SS 304L |

2.0 max |

1.0 max |

17.00 – 19.00 |

0.10 max |

0.045 max |

0.04 – 0.10 |

0.030 max |

9.00 – 12.00 |

4(C+N) – 0.70 max |

ASTM A182 SS 304 Forged Steel Fittings Mechanical Properties

Grades |

Tensile Strength |

Yield Strength (0.2%Offset) |

Melting Point |

Density |

Elongation |

| SS 304 |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

1400 °C (2550 °F) |

8.0 g/cm3 |

35 % |

| SS 304L |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

1400 °C (2550 °F) |

8.0 g/cm3 |

35 % |

| SS 304H |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

1400 °C (2550 °F) |

8.0 g/cm3 |

40 % |

Application

1. Chemical and Petrochemical Processing

Corrosive Fluid Transport: Connects pipes carrying acids, alkalis, or solvents in reactors, distillation columns, and storage tanks.

High-Temperature Lines: Suitable for steam tracing, heat exchangers, and process lines operating up to 925°C (1697°F).

2. Food, Beverage, and Pharmaceutical Industries

Sanitary Systems: Used in hygienic piping for processing milk, juices, or pharmaceuticals (requires smooth, non-reactive surfaces).

3. Oil and Gas

Refinery Piping: Connects pipelines in non-sour (low H₂S) environments for crude oil, natural gas, or refined products.

Utility Steam Lines: Handles steam injection or heat transfer systems.

4. Power Generation

Steam and Boiler Systems: Joins high-pressure steam lines in turbines, condensers, and boilers.

Cooling Water Systems: Used in non-chlorinated cooling loops (e.g., freshwater).

5. Water Treatment and HVAC

Potable Water Systems: Safe for drinking water distribution (low lead leaching risk).

HVAC Ducting: Connects heating/cooling lines in commercial buildings (non-coastal regions).

6. General Industrial and Construction

Heat Exchangers: Links tubes in shell-and-tube or plate heat exchangers.

Hydraulic/Pneumatic Lines: Handles moderate-pressure air or hydraulic fluid lines.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!