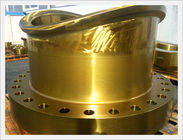

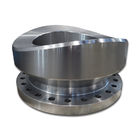

Forged Nozzle flange for boiler and heat exchanger application

Yuhong group supply a lot of Forged Nozzle flange for chemical reactor , ship building , offshore, platform ,

subsea projects,during last 10 years, YUHONG brand goods already exported to more than 55 countries , We

won good reputation in the market.

Almost every heat exchanger is custom designed. Knowing about the possibilities of custom made flanges gives you

as a manufacturer the opportunity to save in welding costs, lead time and additional testing. You can imagine the savings

for fitting when a flange is delivered perfectly shaped to the shell diameter or as a weld-o-let.

Nozzle piece is essential in the interconnection between pressure vessel, heat exchanger or reactor with the rest of process.

The most common forged nozzle used in Oil&Gas and Petrochemical sector are reinforced Long Welding Neck, standard

Long Welding Flange or special flanges that will be weld to the shell. (Not necessary to explain as those interested would

know what a Nozzle is.

Diameter: up to 4,000 mm

Height: up to 3,000 mm

Weight: up to 25 tons

Common Material Grade :

1>.A105, A350 LF2 , LF3, LF6

2>.A105N

3>.A182 F44, F51, F53, F55, F60

4>.A182 F1, F11, F12, F22, F5, F9, F91, F92

5>.A182 F304, F304/304L, F304H, F304L , F309, F310S, F310H, F316, F316L, F316/316L , F316Ti, F316H, F316LN, F317, F317L, F321, F321H, F347, F347H, F904L

6>.A694 F42, F52, F56, F60, F65 ...

Other grade as below :

| Carbon & Low Temperature |

Chromiun |

Stainless & Duplex |

Copper& Bronze |

Titanium |

Ni-Alloy |

| A105 /A105N |

A182-F1 |

A182-F304 |

A182-F347H |

SB151-C70600 |

SB381-GR.F1 |

B564-NO2200 |

| A516-GR.70 |

A182-F11 |

A182-F304L |

A182-F904L |

SB151-C71500 |

SB381-GR.F3 |

B564-NO6022 |

| A350-LF2 |

A182-F12 |

A182-F304H |

A182-F44 |

SB151-C71520 |

SB381-GR.F5 |

B564-N10276 |

| |

A182-F22 |

A182-F304N |

A182-F51 |

C44300 |

|

B564-NO4400 |

| |

A182-F5 |

A182-F309S |

A182-F53 |

C68700 |

|

B564-NO6600 |

| |

A182-F9 |

A182-F310S |

A182-F55 |

C71640 |

|

B564-NO6601 |

| |

A182-F91 |

A182-F310H |

A182-F60 |

|

|

B564-NO6625 |

| |

|

A182-F316 |

|

|

|

B564-NO8800 |

| |

|

A182-F316L |

|

|

|

B564-NO8810 |

| |

|

A182-F316Ti |

|

|

|

B564-NO8811 |

| |

|

A182-F316H |

|

|

|

B564-NO8825 |

| |

|

A182-F317L |

|

|

|

B564-N10665 |

| |

|

A182-F321 |

|

|

|

B564-N10675 |

| |

|

A182-F321H |

|

|

|

B160-NO2201 |

| |

|

A182-F347 |

|

|

|

B462-NO8020 |

Certfiticates List:

| Certificates list for Nozzle flange |

| ISO9001:2008 |

ISO14001:2004 |

PED Certificate |

| ABS Certficate |

BV Certficate |

DNV Certificate |

| RINA Certficate |

GL Certficate |

LR Certficate |

| CCS Certficate |

NK Certficate |

KR Certficate |

| API-6A Certficate |

API-17D Certficate |

CNAS Certficate |

The main manufacturing equipments

| Name&Description |

Capacity |

Quantity |

| 3600Thydraulic press |

Max. single forging in 18T |

1 |

| 2000T hydraulic press |

Max. single forging in 9T |

2 |

| 800 hydraulic press |

Max. single forging in 5T |

1 |

| 6T electrical hydraulic hammer |

Max.single forging in 5T |

1 |

| 3T electrical hydraulic hammer |

Max.single forging in3T |

1 |

| Air hammer |

Max.single forging from250kg to 1000kg |

7 |

| Forging operation machine |

Max.singe forging from20T-5T |

7 |

| Heat treatment Furance |

Max.8000*5000*1500mm |

11 |

| CNC driling machine |

Max.5000mm |

2 |

| Vertical lathe |

From 1600 to 5000mm |

60 |

| Horizontal lathe |

Max.5000mm |

70 |

| Band sawing machine |

260-1300mm |

36 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!