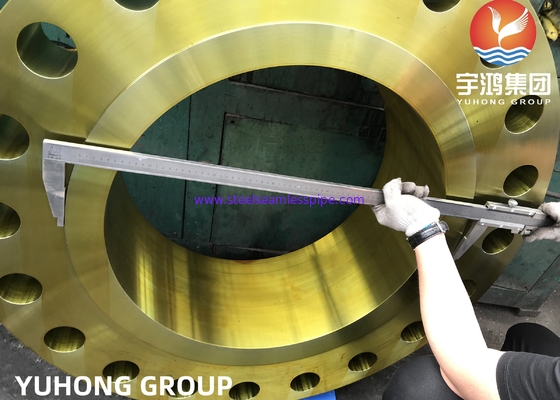

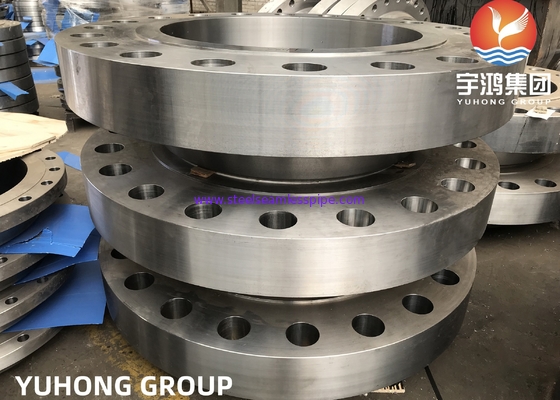

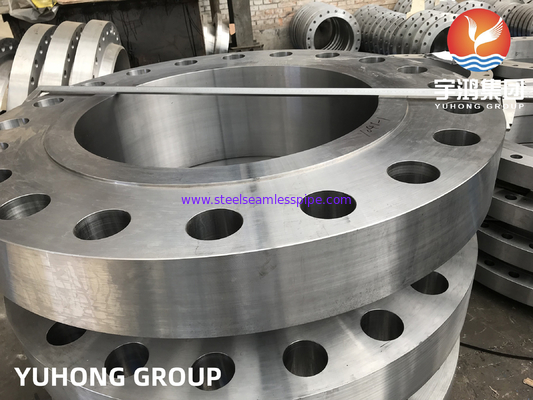

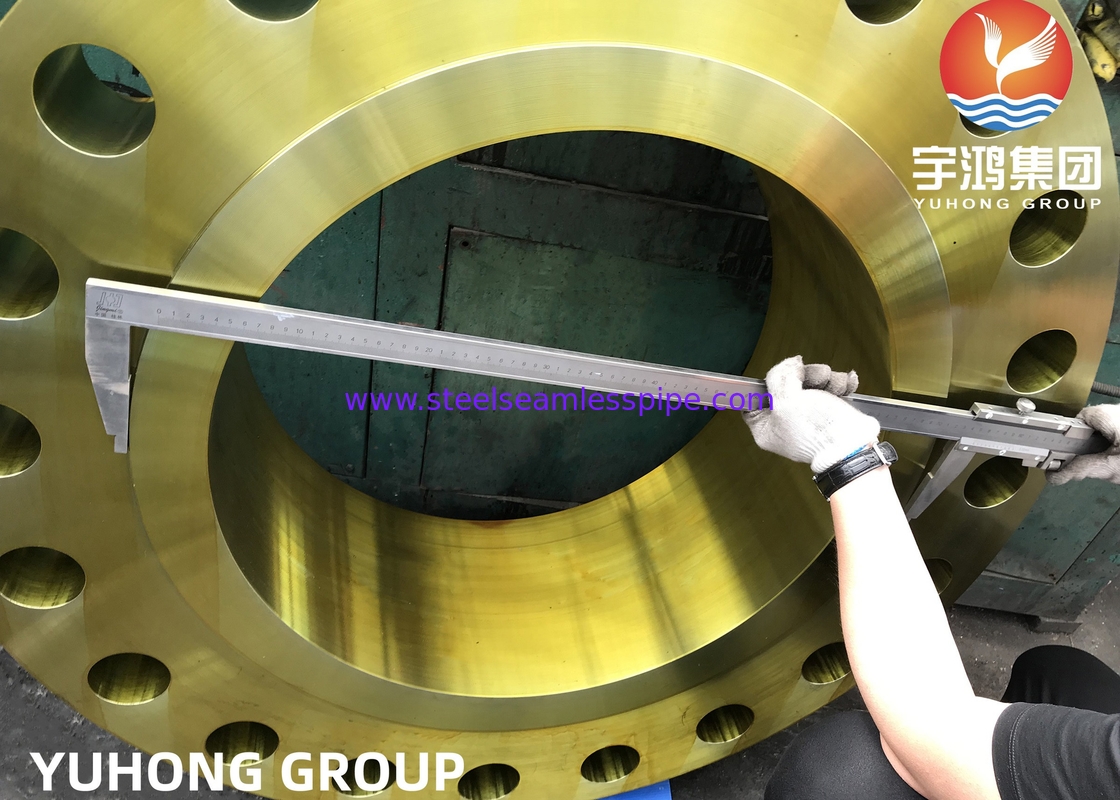

ASTM A694 F52 F60 F65 Pipeline Steel Forged WNRF Flange For Oil And Gas Industries

Our Group company has abundant experience for manufacturing ASTM A694 F52 / F60 / F65 pipeline steel flanges for more than 20 years. We have exported steel flanges to more than 50 countries. These flanges are widely used in applications like oil and gas plants, chemical industries, water treatment systems, etc..

ASTM A694 Standard Scope:

| Grade |

Yield Strength (0.2% offset),min, ksi [MPa] |

Tensile Strength, min, ksi [MPa] |

Elongation in 2 in, or 50 mm, min % |

| F42 |

42 [290] |

60 [415] |

20 |

| F46 |

46 [315] |

60 [415] |

20 |

| F48 |

48 [330] |

62 [420] |

20 |

| F50 |

50 [345] |

64 [440] |

20 |

| F52 |

52 [360] |

66 [455] |

20 |

| F56 |

56 [385] |

68 [470] |

20 |

| F60 |

60 [415] |

75 [515] |

20 |

| F65 |

65 [450] |

77 [530] |

20 |

| F70 |

70 [485] |

82 [565] |

18 |

ASME Standards:

ASME B 16.5 Steel Pipe Flanges and Flanged Fittings

ASME B 16.9 Steel Butt-Welding Fittings

ASME B 16.10 Face-to-Face and End-to-End Dimensions of Ferrous Valves

ASME B 16.11 Forged Steel Fittings, Socket Welding and Threaded

ASME B 16.28 Wrought Steel Butt-Welding Short Radius Elbows

ASME B 16.47 Large Diameter Steel Flanges

MSS Standards:

MSS SP-44 Standard for Steel Pipe Line Flange

MSS SP-75 Specification for High-Test Welding Fittings

MSS SP-95 Swage (d) Nipples and Bull Plugs

MSS SP-97 Integrally Reinforced Forged Branch Outlet Fittings

ASTM A694 F52 Flanges Definition

ASTM A694 F52 Flanges is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.

ASTM A694 F52 Flanges (Standard Specification for Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service)

ASTM A694 F52 Flanges Standard Specification for Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service. Several grades of material, based on minimum yield strength requirements, are covered Materials adhere to testing and tensile property requirements as well.

Specifications:

| Specification |

ASTM A694 / ASME SA694 |

| Manufacturing Process |

Hot Forging / Rolling / Machining |

| Grades |

ASTM A694 F42 / ASTM A694 F46 / ASTM A694 F52 / ASTM A694 F56 / ASTM A694 F60 / ASTM A694 F65 / ASTM A694 F70 / ASME SA694 F42 / ASME SA694 F46 / ASME SA694 F52 / ASME SA694 F56 / ASME SA694 F60 / ASME SA694 F65 / ASME SA694 F70 |

| Outer Diameter |

1/2" NB TO 64" NB |

| Pressure Class |

Class 150#, Class 300#, Class 400#, Class 600#, Class 900#, Class 1500#, Class 2500# or As Per Custom Requirement

PN 6, PN 10, PN 16, PN 25 and PN 40 etc |

| Schedule |

Sch 10s TO Sch XXS or As Per Custom Requirement |

| Facing |

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Dimension |

ASME B16.5, ASME B16.47 SERIES A, ASME B16.47 SERIES B, ASME B16.36, BS10, EN1092-1:2013, MSS SP44, ASA, API-605, ISO 7005, ISO 15590-3, DIN 2631--2638, DIN 2573-2576, DIN 2527, DIn 2641-2642, DIN 2565-2566, DIN2502, AWWA, AS2129 TABLE C, D, E, F, J etc.. |

| Flanges Types |

Welding Neck Flange, Slip On Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Blind Flange, Orifice Flanges, Plate Flange, Long Welding Neck Flanges, Weldoflange, Nipoflange, Expander Flange, Reducing Flange, WNRF Flange, SORF Flange, SWRF Flange, Custom Flange as per Drawing etc. |

| Other Testing |

NACE MR0175, Ultrasounic Test, Charpy Impact Test, Macro, Grain Size, Hardness, HIC, SSC, Sour Service, A for annealed, N for normalized, NT for Normalized and Tempered, or QT for Quenched and Tempered, Carbon Equivalent etc. |

| Value Added Services |

Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Packaging |

Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps |

| Country of Origin |

Made in China |

| Material Test Certificate |

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved etc. |

Chemical Compostion and Properties:

| Chemical Composition of ASTM A694, Heat Analysis, % |

| Carbon [C] |

≤0.30 |

| Manganese [Mn] |

≤1.60 |

| Phosphorus [P] |

≤0.025 |

| Sulfur [S] |

≤0.025 |

| Silicon [Si] |

0.15-0.35 |

Heat treatment:

All forgings should be heat treated. The heat treatment of carbon steel and high-strength low-alloy steel should be normalized, normalized or tempered or quenched and tempered. The heat treatment of alloy steel is aging treatment with quenching and precipitation or aging treatment with quenching and precipitation.

Tempering temperature shall be at least 1000 ℉ [540 ℃], precipitation heat treatment of alloy steel shall be in range from 1000 to 1225 ℉ [540 ℃ to 665 ℃].

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!