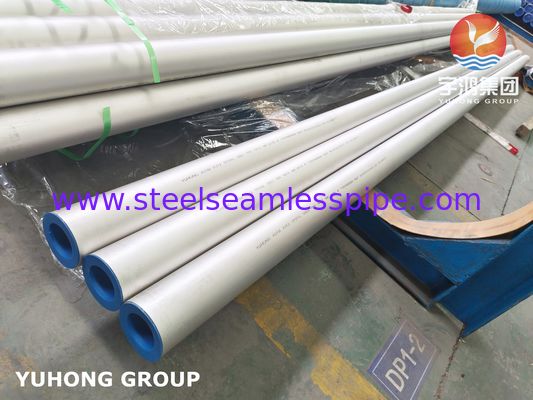

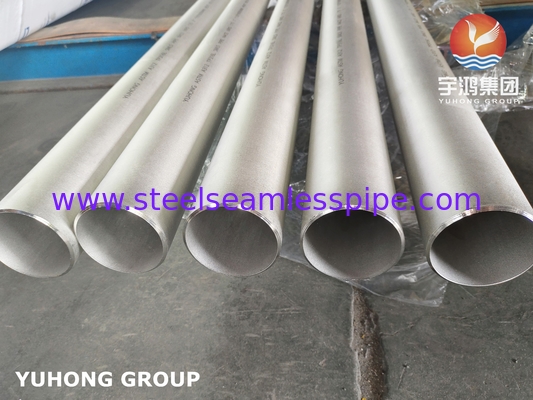

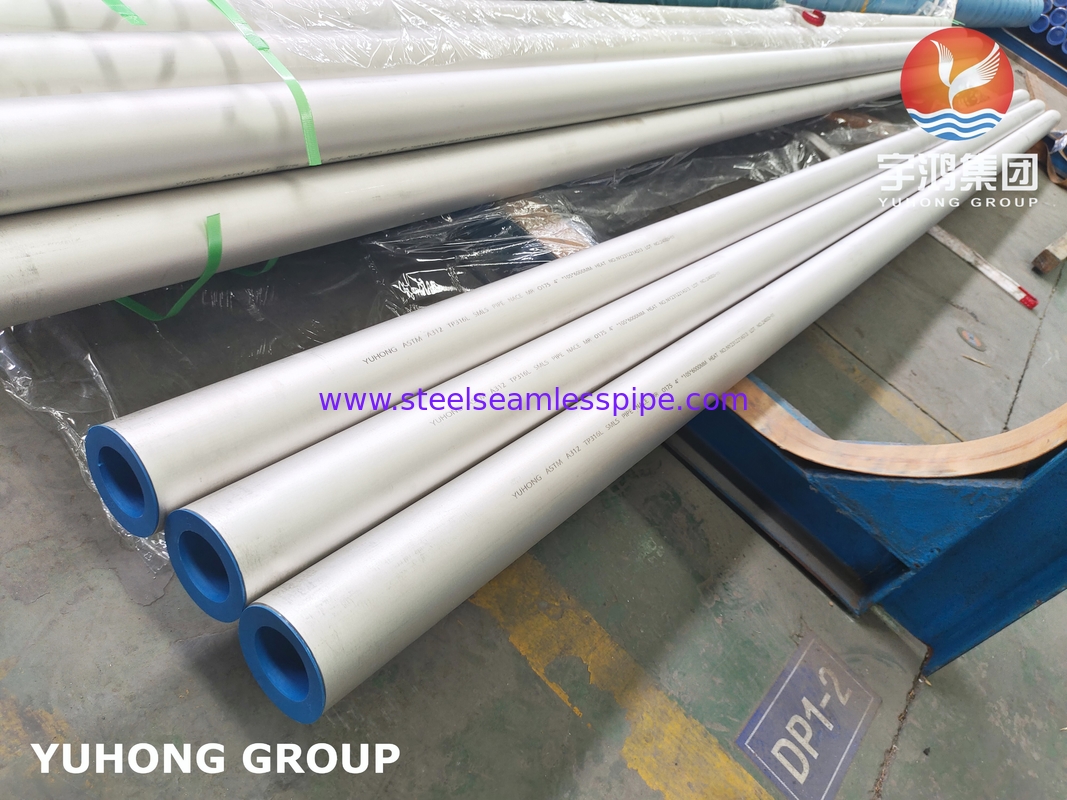

Stainless Steel A312 TP316L Seamless Pipe Nace MR 0175 Standrad

Overview

ASTM A312 TP316L is a grade of seamless and welded stainless steel pipe that is highly resistant to corrosion, especially in chloride-rich environments. Some key details about A312 TP316L pipe:

- Material Composition: TP316L stainless steel has a lower carbon content compared to TP316, making it more resistant to intergranular corrosion and better suited for welding applications. The composition includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.

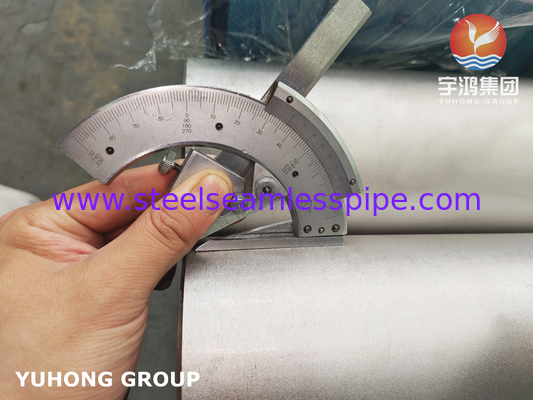

- Mechanical Properties: TP316L pipe has a minimum tensile strength of 485 MPa (70 ksi) and a minimum yield strength of 170 MPa (25 ksi). The minimum elongation is 35%.

- Sizes and Schedules: A312 TP316L pipe is available in sizes from 1/8" NB to 48" NB, with wall thicknesses ranging from Schedule 5S to Schedule 160. Common sizes include 1/2", 1", 2", 4", 6", and 12" NB.

- Manufacturing: The pipes can be produced as seamless or welded (ERW). Seamless pipes are made through a process that does not involve welding at any stage. Welded pipes use an automatic welding process with no filler metal added.

- Applications: Due to its excellent corrosion resistance, A312 TP316L pipe is widely used in the chemical processing, petrochemical, marine, and other industries that require piping systems to handle corrosive fluids and environments.

NACE MR0175, also known as ISO 15156, is a widely recognized international standard developed by the National Association of Corrosion Engineers (NACE) International. This standard provides requirements and recommendations for the selection and qualification of materials for equipment used in oil and gas production environments where sour (containing hydrogen sulfide) service conditions are present.

Here are some key points regarding NACE MR0175: Sour Service Environments, Material Selection, Material Qualification, Compliance, Global Recognition.

NACE MR0175 is a vital standard that helps to ensure the safe and reliable operation of equipment in sour service environments by providing guidelines for the selection and qualification of materials that can withstand the challenges posed by hydrogen sulfide and related contaminants.

Comparasion between SS316 and SS316L

- - Different carbon contents

The carbon content of 316L is lower than that of 316 stainless steel, with a carbon content below 0.03%, while the carbon content of 316 stainless steel is below 0.08%. This lower carbon content gives 316L stainless steel better corrosion resistance and toughness.

Due to its better corrosion resistance and toughness, 316L stainless steel is usually priced higher than 316 stainless steel.

- - Different application fields

Although 316L and 316 stainless steel have applications in many fields, their application areas are slightly different. For example, due to its better corrosion resistance and toughness, 316L stainless steel is commonly used in high demand fields such as manufacturing medical devices, chemical equipment, and food processing equipment. 316 stainless steel is more commonly used in ordinary fields such as manufacturing pipelines, water tanks, and stoves.

- - Different wire drawing treatments after heat treatment

After heat treatment, 316L stainless steel usually needs to undergo acid washing and polishing treatment to remove surface oxides and impurities, ensuring its surface quality. 316 stainless steel requires wire drawing treatment to obtain a better surface texture.

Although 316L and 316 stainless steel are very similar in many aspects, the slight differences between them make them exhibit different properties in different application fields. Therefore, when choosing which type of stainless steel to use, a decision needs to be made based on specific application requirements.

Chemical Composition for SS316L

|

Grade

|

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

|

|

316L

|

Min

|

-

|

-

|

-

|

-

|

-

|

16.0

|

2.00

|

10.0

|

-

|

|

Max

|

0.03

|

2.0

|

0.75

|

0.045

|

0.03

|

18.0

|

3.00

|

14.0

|

0.10

|

Mechanical Properties for SS316L

|

Grade

|

Tensile Str (MPa) min

|

Yield Str 0.2% Proof (MPa) min

|

Elong (% in 50 mm) min

|

Hardness

|

|

Rockwell B (HRB) max

|

Brinell (HB) max

|

|

316L

|

485

|

170

|

40

|

95

|

217

|

Application

The ASTM A312 TP316L stainless steel pipe is widely used in various industries due to its excellent corrosion resistance and mechanical properties. Here are some common applications of TP316L pipes:

- Chemical Processing

- Petrochemical Industry

- Marine Applications

- Pharmaceutical Industry

- Food and Beverage Industry

- Water Treatment Plants

- Medical Equipment

In medical applications, TP316L pipes are utilized in the construction of medical devices, surgical instruments, and equipment that require high levels of cleanliness, corrosion resistance, and biocompatibility.

Overall, the versatility, durability, and corrosion-resistant properties of ASTM A312 TP316L stainless steel pipes make them a preferred choice for a wide range of industries, including chemical processing, petrochemicals, marine, pharmaceuticals, food and beverage, water treatment, and medical equipment manufacturing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!