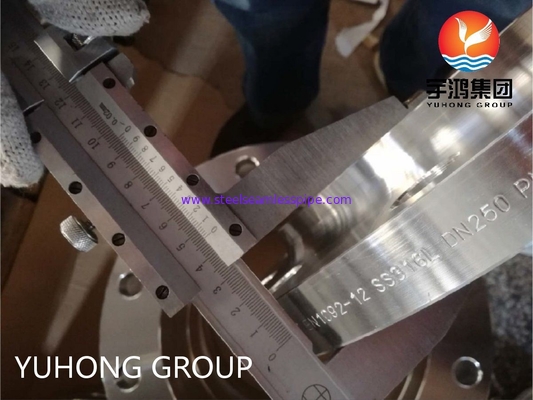

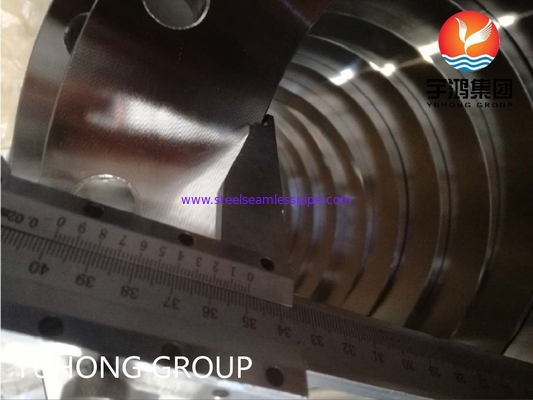

ASTM A182 F316L Stainless Steel Forged SO Flange EN1092-1 Type12 DN250 PN16

Yuhong Group has an experienced team dedicated to the research and development of flanges, and can customize various products according to the different requirements of customers. We promise that every product will be inspected and confirmed in accordance with current Good Manufacturing Practices. Our team is united, pragmatic and forward-looking. Our development is inseparable from the care and companionship of all customers and partners. We continuously improve the technological content of our products and successfully develop energy-saving products that meet international standards. The company is based on the local area, looks at the world, and continuously improves its strength with cutting-edge technology.

Our range of ASTM A182 F316L flanges are ideal for excessive pressure and temperature applications in the manifold industry. The addition of molybdenum and nickel provides excellent sub-zero notch ductility superior to other standard 410, 13 Cr and 420 Mod martensitic stainless steels. ASME SA 182 F316L material is air hardened and has little risk of cracking in thick sections when heat treated. We manufacture 316L stainless steel flanges in special sizes and custom shapes for our customers. Molybdenum imparts better overall corrosion resistance to stainless steel 316L slip flanges than grade 304. SS 316L blind flanges are standard for austenitic stainless steel varieties.

Type 316L stainless steel flanges are widely used for heavy duty welded parts (about 6mm+)

There is no significant price difference between SS 316L blind flanges and 316 SS flanges. Stainless Steel 316L plate flanges are also easier to machine than 316 stainless steel due to its lower carbon content. 316L SS slip flanges will not harden by heat treatment. It can be hardened by cold work.

This can also lead to increased strength. 316L flat flanges are mostly used for stainless steel flanges family. The ultimate tensile strength (UTS) of SS 316L eyeglass blind flanges has excellent formability and welding characteristics. SS 316L butt weld flange austenitic structure also makes these grades perform well Toughness, even down to low temperatures.

1. Stainless Steel 316 / 316L Flanges Specification

Specification : ASTM A182 / ASME SA182

Dimension : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Size : 1/2" (15 NB) to 48" (1200NB)

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Class / Pressure Rating : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64. etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

2. Stainless Steel 316 / 316L Pipe Flanges Manufacturing Standards :

|

ASME/ANSI

B16.5

|

Welding Neck Flange, Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS |

150, 300, 400, 600, 900, 1500, 2500 |

|

ASME/ANSI

B16.47

|

Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS |

75, 150, 300, 400, 600, 900 |

|

ASME/ANSI

B16.36

|

Welding Neck Flange, Slip on Flange, Threaded Flange |

| PRESSURE CLASS |

300, 400, 600, 900, 1500, 2500 |

|

BS 4504

SEC 3.1

|

Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS |

PN 2.5 TO PN 40 |

|

BS 4504

[PART 1]

|

Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS |

PN 2.5 TO PN 400 |

| BS 1560 BOSS |

Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS |

150, 300, 400, 600, 900, 1500, 2500 |

| BS10 |

Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE |

D, E, F, H |

| DIN FLANGES |

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS |

PN 6 TO PN 100 |

3. ASME SA182 Stainless Steel 316 / 316L Pipe Flanges Equivalent Standards

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

| SS 316 |

1.4401 / 1.4436 |

S31600 |

SUS 316 |

316S31 / 316S33 |

- |

Z7CND17‐11‐02 |

X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L |

1.4404 / 1.4435 |

S31603 |

SUS 316L |

316S11 / 316S13 |

03Ch17N14M3 / 03Ch17N14M2 |

Z3CND17‐11‐02 / Z3CND18‐14‐03 |

X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Chemical Composition of Grade 316 / 316L Stainless Steel Plate Flanges

| Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

Fe |

| SS 316 |

0.08 max |

2.0 max |

1.0 max |

0.045 max |

0.030 max |

16.00 - 18.00 |

2.00 - 3.00 |

11.00 - 14.00 |

67.845 min |

| SS 316L |

0.035 max |

2.0 max |

1.0 max |

0.045 max |

0.030 max |

16.00 - 18.00 |

2.00 - 3.00 |

10.00 - 14.00 |

68.89 min |

Mechanical Properties of ASTM A182 SS UNS S31600 / S31603 Industrial Flanges

| Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| 8.0 g/cm3 |

1400 °C (2550 °F) |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

35 % |

| 8.0 g/cm3 |

1399 °C (2550 °F) |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

35 % |

4. Size Range:

1/2" ~ 24" (DN15 ~ DN600)

Dimensions and weights of Class 150 Flange

|

SIZE

|

FLANGE

|

BARREL

|

BOLTING

|

Raised

Face Dia.

R

|

LENGTH

L

|

WEIGHT

|

|

Nom

|

Unit

|

Bore

B

|

OD

O

|

Thk

T

|

OD

D

|

No. OF

Holes

|

Hole

Size

|

Bolt

Circle

C

|

POUND

KILO

|

|

1/2

|

mm

inches

|

12,7

0,50

|

88,9

3,50

|

11,2

0,44

|

31,8

1,25

|

4

|

15,7

0,62

|

60,5

2,38

|

34,9

1,38

|

228,6

9,00

|

3

1,36

|

|

3/4

|

mm

inches

|

19,1

0,75

|

98,6

3,88

|

12,7

0,50

|

41,1

1,62

|

4

|

15,7

0,62

|

69,9

2,75

|

42,9

1,69

|

228,6

9,00

|

5

2,27

|

|

1

|

mm

inches

|

25,4

1,00

|

108,0

4,25

|

14,2

0,56

|

50,8

2,00

|

4

|

15,7

0,62

|

79,2

3,12

|

50,8

2,00

|

228,6

9,00

|

7

3,17

|

|

1 1/4

|

mm

inches

|

31,8

1,25

|

117,3

4,62

|

15,7

0,62

|

60,5

2,38

|

4

|

15,7

0,62

|

88,9

3,50

|

63,5

2,50

|

228,6

9,00

|

10

4,54

|

|

1 1/2

|

mm

inches

|

38,1

1,50

|

127,0

5,00

|

15,5

0,69

|

66,5

2,62

|

4

|

15,7

0,62

|

98,6

3,88

|

73,0

2,88

|

228,6

9,00

|

12

5,44

|

|

2

|

mm

inches

|

50,8

2,00

|

152,4

6,00

|

19,1

0,75

|

82,6

3,25

|

4

|

19,1

0,75

|

120,7

4,75

|

92,1

3,63

|

228,6

9,00

|

15

6,81

|

|

2 1/2

|

mm

inches

|

63,5

2,50

|

177,8

7,00

|

22,4

0,88

|

95,3

3,75

|

4

|

19,1

0,75

|

139,7

5,50

|

104,8

4,13

|

228,6

9,00

|

22

9,98

|

|

3

|

mm

inches

|

76,2

3,00

|

190,5

7,50

|

23,9

0,94

|

108,0

4,25

|

4

|

19,1

0,75

|

152,4

6,00

|

127,0

5,00

|

228,6

9,00

|

25

11,35

|

|

3 1/2

|

mm

inches

|

88,9

3,50

|

215,9

8,50

|

23,9

0,94

|

124,0

4,88

|

8

|

19,1

0,75

|

177,8

7,00

|

139,7

5,50

|

228,6

9,00

|

32

14,52

|

|

4

|

mm

inches

|

101,6

4,00

|

228,6

9,00

|

23,9

0,94

|

139,7

5,50

|

8

|

19,1

0,75

|

190,5

7,50

|

157,2

6,19

|

304,8

12,00

|

47

21,33

|

|

5

|

mm

inches

|

127,0

5,00

|

254,0

10,00

|

23,9

0,94

|

165,1

6,50

|

8

|

22,4

0,88

|

215,9

8,50

|

185,7

7,31

|

304,8

12,00

|

57

25,87

|

|

6

|

mm

inches

|

152,4

6,00

|

279,4

11,00

|

25,4

1,00

|

196,9

7,75

|

8

|

22,4

0,88

|

241,3

9,50

|

215,9

8,50

|

304,8

12,00

|

75

34,05

|

|

8

|

mm

inches

|

203,2

8,00

|

342,9

13,50

|

29,4

1,12

|

247,7

9,75

|

8

|

22,4

0,88

|

298,5

11,75

|

269,9

10,63

|

304,8

12,00

|

102

46,30

|

|

10

|

mm

inches

|

254,0

10,00

|

406,4

16,00

|

30,2

1,19

|

304,8

12,00

|

12

|

25,4

1,00

|

362,0

14,25

|

323,9

12,75

|

304,8

12,00

|

143

64,92

|

|

12

|

mm

inches

|

304,8

12,00

|

482,6

19,00

|

31,8

1,25

|

365,3

14,38

|

12

|

25,4

1,00

|

431,8

17,00

|

381,0

15,00

|

304,8

12,00

|

205

93,07

|

|

14

|

mm

inches

|

355,6

14,00

|

133,4

31,00

|

35,1

1,38

|

406,4

16,00

|

12

|

28,4

1,12

|

476,3

18,75

|

412,8

16,25

|

304,8

12,00

|

211

95,79

|

|

16

|

mm

inches

|

406,4

16,00

|

596,9

23,50

|

36,6

1,44

|

457,2

18,00

|

16

|

28,4

1,12

|

539,8

21,25

|

469,9

18,50

|

304,8

12,00

|

246

111,68

|

|

18

|

mm

inches

|

457,2

18,00

|

635,0

25,00

|

3,96

1,56

|

508,0

20,00

|

16

|

31,8

1,25

|

577,9

22,75

|

533,4

21,00

|

304,8

12,00

|

270

122,.58

|

|

20

|

mm

inches

|

508,0

20,00

|

698,5

25,50

|

42,9

1,69

|

558,8

22,00

|

20

|

31,8

1,25

|

635,0

25,00

|

584,2

23,00

|

304,8

12,00

|

311

141,19

|

|

24

|

mm

inches

|

609,6

24,00

|

812,8

32,00

|

4,78

1,88

|

666,8

26,25

|

20

|

35,1

1,38

|

749,3

29,50

|

692,2

27,25

|

304,8

12,00

|

423

192,04

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!