| Specifications |

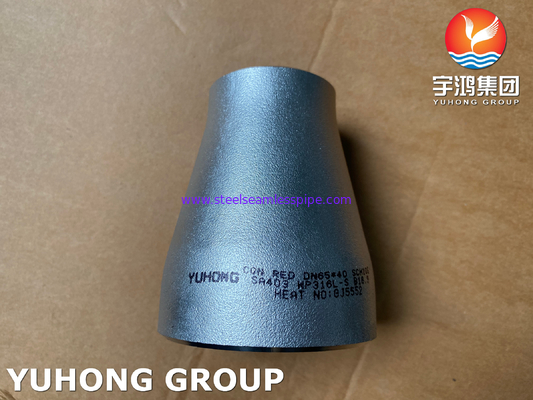

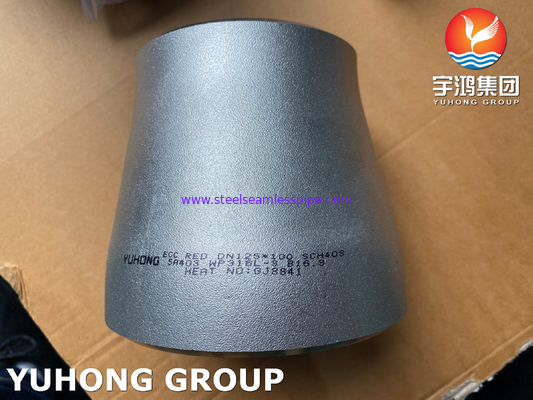

ASTM A403 / ASME SA403 |

| Pipe Fittings size |

Seamless Stainless Steel Butt Weld Fittings: 1/2" - 10"

Welded Stainless Steel Butt Weld Fittings: 1/2" - 48" |

| Pipe Fittings Dimensions |

ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Pipe Fittings Thickness |

SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Pipe fittings Types |

Seamless / ERW / Welded / Fabricated |

| Manufacturing Standards |

ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011, DN15-DN1200

BS : BS4504, BS4504, BS1560, BS10

JIS : JIS B2311, JIS B2312, JIS B2313, JIS B2316

GOST : GOST 17375, GOST 17376, GOST 30753, GOST 17378, GOST 17379, GOST 17380

EN: EN10253-1, EN10253-2 |

| Bending Radius |

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Connection |

Welding |

| Pipe Fittings Elbow |

Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D.

Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Pipe Fittings Size Range |

1/2" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Pipe Fittings Manufacturing process |

Push, Press, Forge, Cast, etc. |

| Buttweld Fittings Test Certificates |

- EN 10204/3.1B

- Raw Materials Certificate

- 100% Radiography Test Report

- Third Party Inspection Report, etc

|

| Specialized manufacturer of |

90º Elbows, Couplings, Reducers, Inserts, Caps, Nipples, 45º Elbows, Tees, Crosses, Equal Tees & Reducing Tees |

| Pipe Fittings uses & application |

- Fittings To Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy, Shipbuilding etc

- Schedule 10 Stainless Steel 317L fittings are an economical alternative for lower-pressure applications.

- Schedule 40 Steel 317L fittings have a thicker wall for higher-pressure applications.

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!