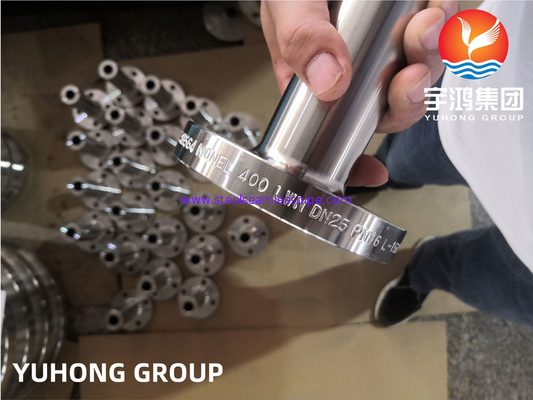

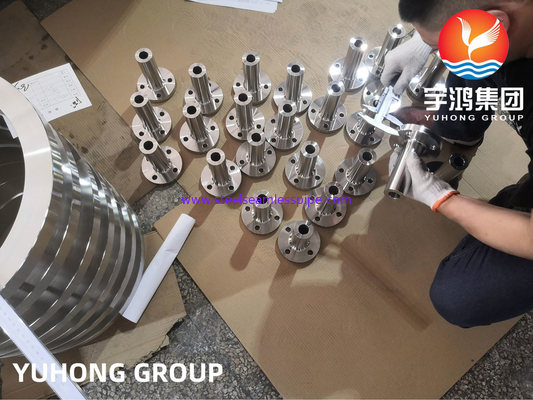

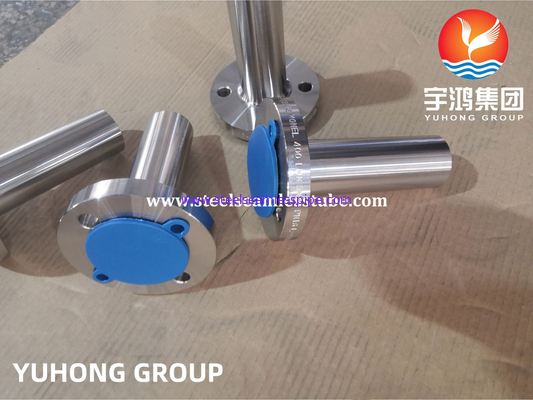

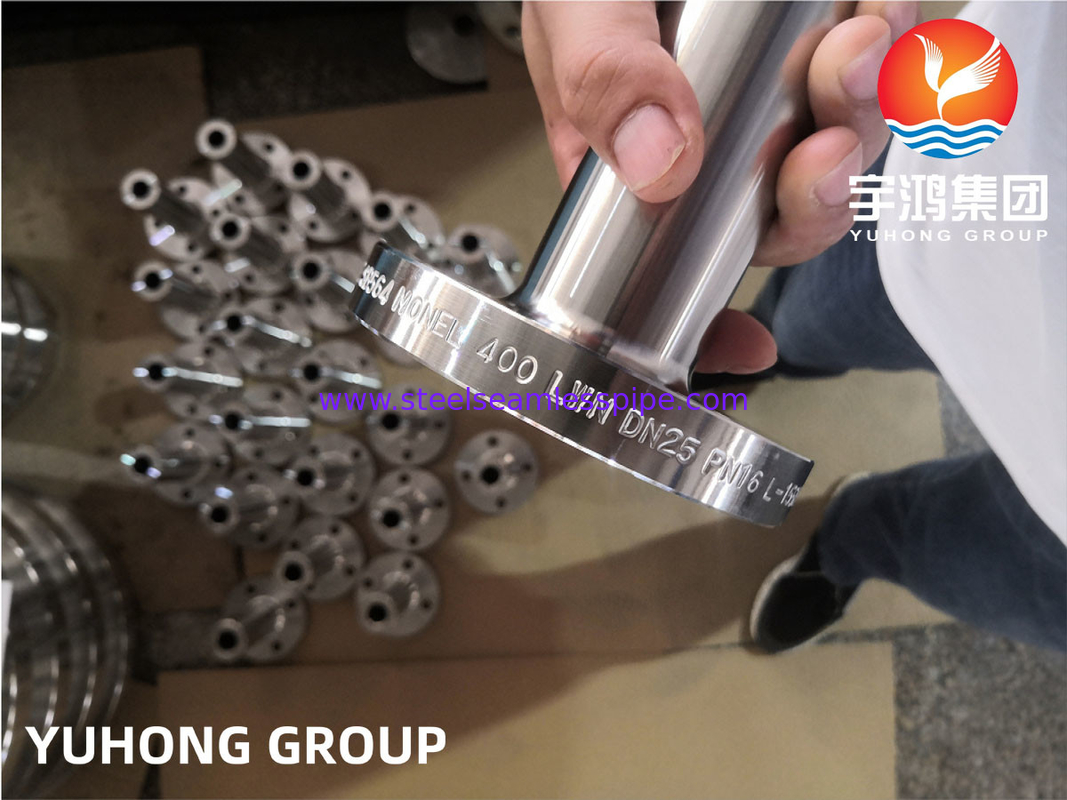

ASTM B564 Monel Alloy 400 LWN Flange Long Welded Neck Flange

YUHONG GROUP deal with Austenitic Stainless Steel, Nickel Alloy Steel(Hastelloy, Monel, Inconel, Incoloy) seamless and welded pipe and tube already more than 25 years, every year sell more than 80000 tons of steel pipe and tube.

Our client already cover more than 45 countries, like Italy, UK, Gernmany, USA, Canada, Chile, Colombia, Saudi Arabia, Korea, Singapore, Australia, Poland, France, etc. And our group branch company and factory have been already approved by : ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004.

Monel 400 is a very popular nickel-copper alloy with better properties, which is often used in more critical and high-performance applications. Monel 400 has high strength, excellent acid and alkali resistance, and good thermal conductivity and ductility. This alloy can maintain its excellent characteristics and performance in the temperature range of minus to 1,000°F (538°C). Monel 400 can only be hardened by cold working.

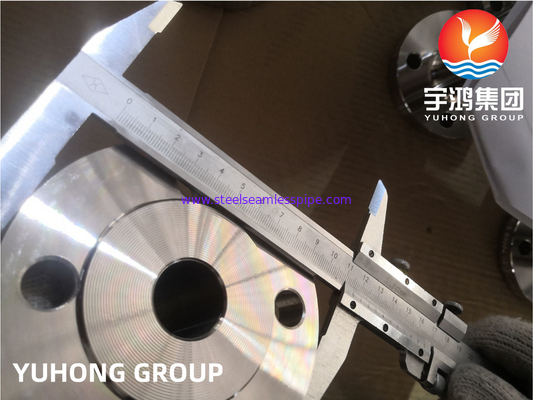

Full Specification for Weld Neck Flange:

1. Standards:

(1) American Standard

ASME/ANSI B 16.5

(2) German Standard

DIN2641, DIN2642

(3) British Standard

BS 1560, BS 4504

(4) Australian & Japanese Standard

JIS B2220 / KS B1503, AS2129,

2. Material:

UNS N04400, N04401, N04404, N05500, N04405

3. Pressure Ratings:

PN2.5, PN6, PN10, PN16, PN25, PN40, PN64, PN80, PN100, PN250, PN320, PN400

150LB, 300LB, 400LB, 600LB, 900LB, 1500LB, 2500LB;

4. Size Range:

1/2" ~ 24" (DN15 ~ DN600)

1. Technical Drawing of Class 150 Long Weld Neck Flange

2. Dimensions and weights of Class 150 Long Weld Neck Flange

|

SIZE

|

FLANGE

|

BARREL

|

BOLTING

|

Raised

Face Dia.

R

|

LENGTH

L

|

WEIGHT

|

|

Nom

|

Unit

|

Bore

B

|

OD

O

|

Thk

T

|

OD

D

|

No. OF

Holes

|

Hole

Size

|

Bolt

Circle

C

|

POUND

KILO

|

|

1/2

|

mm

inches

|

12,7

0,50

|

88,9

3,50

|

11,2

0,44

|

31,8

1,25

|

4

|

15,7

0,62

|

60,5

2,38

|

34,9

1,38

|

228,6

9,00

|

3

1,36

|

|

3/4

|

mm

inches

|

19,1

0,75

|

98,6

3,88

|

12,7

0,50

|

41,1

1,62

|

4

|

15,7

0,62

|

69,9

2,75

|

42,9

1,69

|

228,6

9,00

|

5

2,27

|

|

1

|

mm

inches

|

25,4

1,00

|

108,0

4,25

|

14,2

0,56

|

50,8

2,00

|

4

|

15,7

0,62

|

79,2

3,12

|

50,8

2,00

|

228,6

9,00

|

7

3,17

|

|

1 1/4

|

mm

inches

|

31,8

1,25

|

117,3

4,62

|

15,7

0,62

|

60,5

2,38

|

4

|

15,7

0,62

|

88,9

3,50

|

63,5

2,50

|

228,6

9,00

|

10

4,54

|

|

1 1/2

|

mm

inches

|

38,1

1,50

|

127,0

5,00

|

15,5

0,69

|

66,5

2,62

|

4

|

15,7

0,62

|

98,6

3,88

|

73,0

2,88

|

228,6

9,00

|

12

5,44

|

|

2

|

mm

inches

|

50,8

2,00

|

152,4

6,00

|

19,1

0,75

|

82,6

3,25

|

4

|

19,1

0,75

|

120,7

4,75

|

92,1

3,63

|

228,6

9,00

|

15

6,81

|

|

2 1/2

|

mm

inches

|

63,5

2,50

|

177,8

7,00

|

22,4

0,88

|

95,3

3,75

|

4

|

19,1

0,75

|

139,7

5,50

|

104,8

4,13

|

228,6

9,00

|

22

9,98

|

|

3

|

mm

inches

|

76,2

3,00

|

190,5

7,50

|

23,9

0,94

|

108,0

4,25

|

4

|

19,1

0,75

|

152,4

6,00

|

127,0

5,00

|

228,6

9,00

|

25

11,35

|

|

3 1/2

|

mm

inches

|

88,9

3,50

|

215,9

8,50

|

23,9

0,94

|

124,0

4,88

|

8

|

19,1

0,75

|

177,8

7,00

|

139,7

5,50

|

228,6

9,00

|

32

14,52

|

|

4

|

mm

inches

|

101,6

4,00

|

228,6

9,00

|

23,9

0,94

|

139,7

5,50

|

8

|

19,1

0,75

|

190,5

7,50

|

157,2

6,19

|

304,8

12,00

|

47

21,33

|

|

5

|

mm

inches

|

127,0

5,00

|

254,0

10,00

|

23,9

0,94

|

165,1

6,50

|

8

|

22,4

0,88

|

215,9

8,50

|

185,7

7,31

|

304,8

12,00

|

57

25,87

|

|

6

|

mm

inches

|

152,4

6,00

|

279,4

11,00

|

25,4

1,00

|

196,9

7,75

|

8

|

22,4

0,88

|

241,3

9,50

|

215,9

8,50

|

304,8

12,00

|

75

34,05

|

|

8

|

mm

inches

|

203,2

8,00

|

342,9

13,50

|

29,4

1,12

|

247,7

9,75

|

8

|

22,4

0,88

|

298,5

11,75

|

269,9

10,63

|

304,8

12,00

|

102

46,30

|

|

10

|

mm

inches

|

254,0

10,00

|

406,4

16,00

|

30,2

1,19

|

304,8

12,00

|

12

|

25,4

1,00

|

362,0

14,25

|

323,9

12,75

|

304,8

12,00

|

143

64,92

|

|

12

|

mm

inches

|

304,8

12,00

|

482,6

19,00

|

31,8

1,25

|

365,3

14,38

|

12

|

25,4

1,00

|

431,8

17,00

|

381,0

15,00

|

304,8

12,00

|

205

93,07

|

|

14

|

mm

inches

|

355,6

14,00

|

133,4

31,00

|

35,1

1,38

|

406,4

16,00

|

12

|

28,4

1,12

|

476,3

18,75

|

412,8

16,25

|

304,8

12,00

|

211

95,79

|

|

16

|

mm

inches

|

406,4

16,00

|

596,9

23,50

|

36,6

1,44

|

457,2

18,00

|

16

|

28,4

1,12

|

539,8

21,25

|

469,9

18,50

|

304,8

12,00

|

246

111,68

|

|

18

|

mm

inches

|

457,2

18,00

|

635,0

25,00

|

3,96

1,56

|

508,0

20,00

|

16

|

31,8

1,25

|

577,9

22,75

|

533,4

21,00

|

304,8

12,00

|

270

122,.58

|

|

20

|

mm

inches

|

508,0

20,00

|

698,5

25,50

|

42,9

1,69

|

558,8

22,00

|

20

|

31,8

1,25

|

635,0

25,00

|

584,2

23,00

|

304,8

12,00

|

311

141,19

|

|

24

|

mm

inches

|

609,6

24,00

|

812,8

32,00

|

4,78

1,88

|

666,8

26,25

|

20

|

35,1

1,38

|

749,3

29,50

|

692,2

27,25

|

304,8

12,00

|

423

192,04

|

Flanges are part of the piping system and are used inside or outside the pipeline. Many types of flanged pipes are generally used in piping systems. Flanges are like bridges, connecting pipes or fittings, making the pipe a complete system. Flange is an indispensable part of connecting piping.

Piping fittings are parts for installing or repairing pipelines or piping systems that transport liquid, gas, and solid materials. This work includes selecting and preparing pipe or tube, connecting them together in various ways, as well as locating and fixing vulnerabilities.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!