| Standard Specifications |

ASTM A182 / A240 & ASME SA182 / SA240 |

| Dimensions |

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard |

- BS (British Standard)

- DIN, EN (European)

- ASA/ANSI/ASME B16.5/16.36/16.47A/16.47B

- B16.47 Series A & B

- B16.48

- BS4504

- BS 10

- EN-1092

- GOST Flange

- MSS S44

- ISO 70051

- JIS B2220

- BS1560-3.1

- API 7S-15

- API 7S-43

- API 605

- EN 1092

|

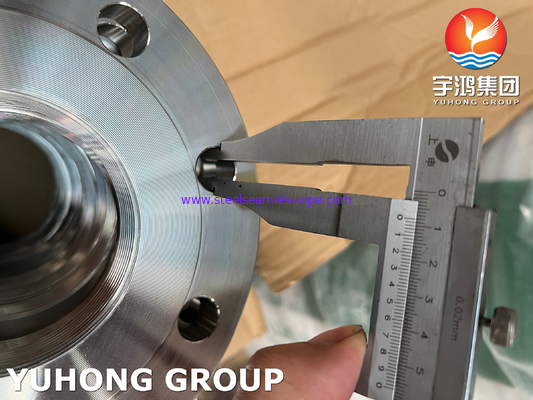

| Size Range |

1/2" (15 NB) to 48" (1200NB) DN10~DN5000 or special sizes |

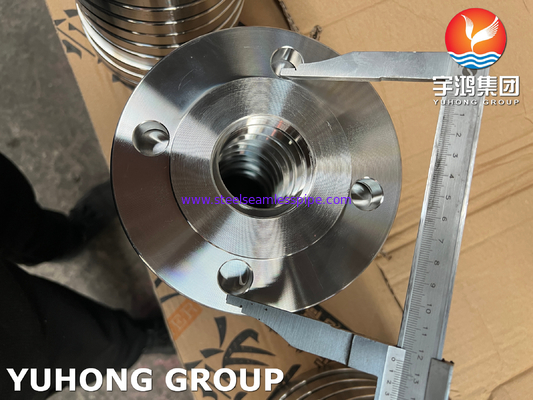

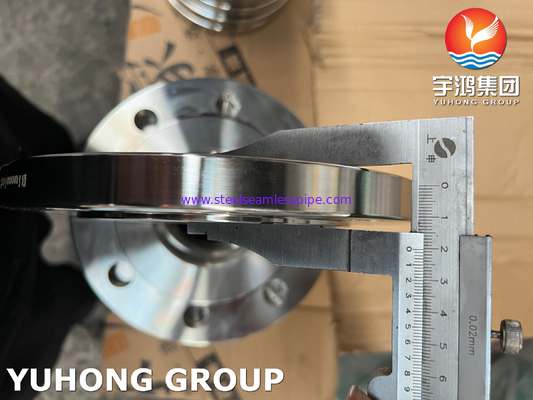

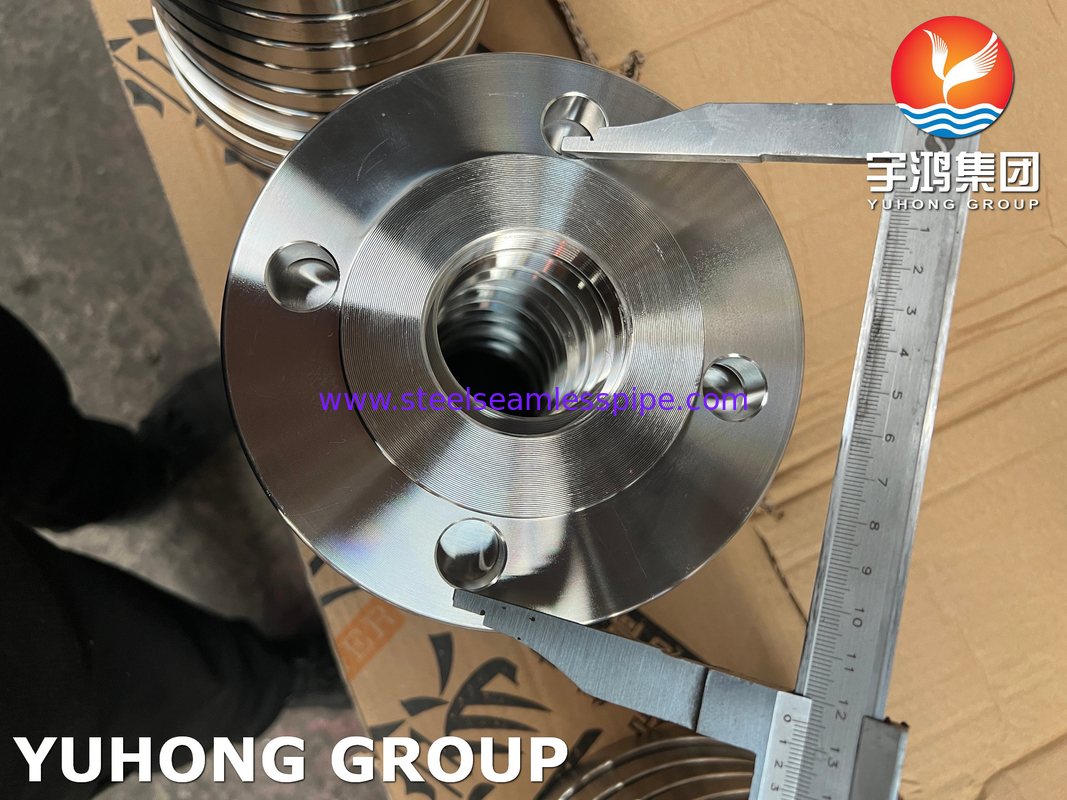

| Connect Type/ Flange Face Type |

Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Pressure Rating ANSI |

Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN |

6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS |

5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| UNI |

6Bar 10Bar 16Bar 25Bar 40Bar |

| EN |

6Bar 10Bar 16Bar 25Bar 40Bar |

| Most common types |

Forged / Threaded / Screwed / Plate |

| Test Certificates |

EN 10204/3.1B

Raw Materials Certificate

100% Radiography Test Report

Third Party Inspection Report, etc |

| Production technique |

- Forged, Heat treated and machined

|

| Special design |

As per your drawing

AS, ANSI, BS, DIN and JIS

15 NB (1/2") to 200 NB (8")

Equal and Reducing Configurations

|

| Origin |

China |

| Uses & application |

- Bitumen upgraders.

- Heavy oil refineries.

- Nuclear power (mostly seamless).

- Petrochemicals and acids.

|

| We produce |

- B.S: BS4504 , BS3293, BS1560, BS10

- AS 2129: Table D; Table E; Table H

- ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48

- ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

- American standard (ANSI)

- German (DIN)

- British standard (BS)

- DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638

- The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276

|

| Export to |

Dubai, UAE, Indonesia, Ireland, Malaysia, Singapore,Egypt, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Oman, Peru, etc

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!