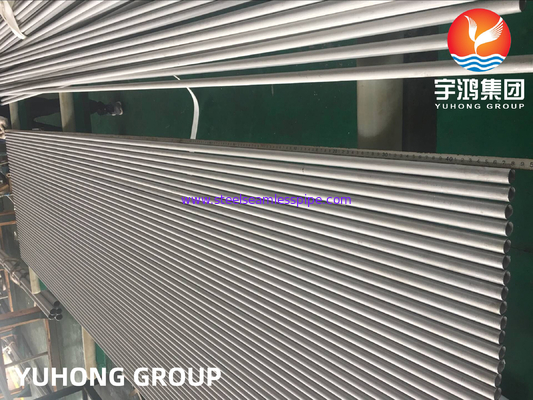

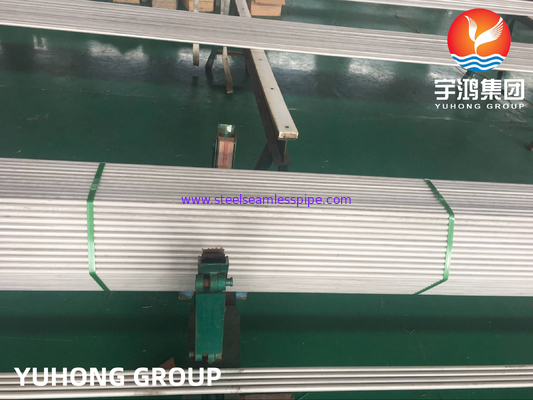

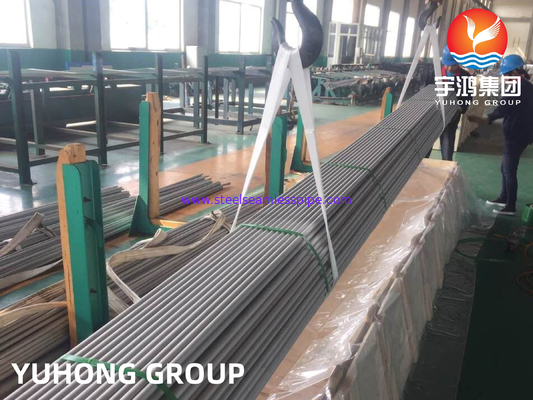

ASME SA213 TP321 / TP321H/1.4541, Stainless Steel Seamless Tube, Heat Exchanger / Boiler Application

Yuhong Group has more than 33 years experience for heat exchanger tube / boiler tube/ cooling tube,

The addition of titanium also provides the ASTM A213 Tp 321 pipes with high corrosion resistance properties. The intergranular corrosion risk present in most high carbon steels is reduced in the 321 Stainless Steel Tube due to the addition of titanium. The 321 Stainless Steel Exhaust Tubing can last longer in high temperatures. Therefore the 321 Stainless Steel Seamless Tube is used in heat exchangers and in super heaters. There are different types of these pipes such as the 321 Stainless Steel Flexible Tube which is easy to install and to maintain. The application of the Type 321 Stainless Steel Tube can also be seen in boilers and in condensers. We produce high quality 321 SS Tube in different sizes and types. Our SS 321 Seamless Tube is suitable for smaller size piping with high accuracy. This corrosion resistant steel could also be identified as the 321 Cres Tube. Our customers can get custom finishes of these pipes as well. Please contact us with any of your inquiries on product details or pricing.

TP321 is a stabilized stainless steel which offers as its main advantage an excellent resistance to intergranular corrosion following exposure to temperature in the chromium carbide precipitation range from 800 °F to 1500°F (427°C to 816°C). Alloy 321 stainless steel tubing is stabilized against chromium carbide formation by the addition of titanium.TP321 TP321H Stainless Steel is a titanium-stabilised version of TP304, used in particular applications within the sensitizing temperature range. Its resistance to sensitization, coupled with its higher strength at high temperature makes it suitable in applications where 304 will become sensitized, or where TP304L has insufficient hot strength. It is not subject to weld decay intergranular corrosion when exposed to mildly corrosive environments. However, welded 321 must never be used in highly oxidising environments as it is liable to ‘Knife-line’ attack. However, 321 is a much better option in operating temperature environments in excess of 500° C and therefore has its own merits. Alloy 321 stainless steel tube is also advantageous for high temperature service because of its good mechanical properties. Alloy 321 stainless steel offers higher creep and stress rupture properties than Alloy 304 and, particularly, Alloy 304L also be considered for exposure where sensitization and intergranular corrosion are concern.TP321 TP321H stainless steel is basically from 304 stainless steel. They different by a very very small addition of Titanium. The real difference is their carbon content. The higher the carbon content the greater the yield strength. 321 stainless steel has advantages in a high temperature environment due to its excellent mechanical properties. Compared with 304 alloy, 321 stainless steel has better ductility and resistance to stress fracture. In addition, 304L can also be used for anti-sensitization and intergranular corrosion.Grade TP304L is more readily available in most product forms, and so is generally used in preference to 321 if the requirement is simply for resistance to intergranular corrosion after welding. However 304L has lower hot strength than 321 and so is not the best choice if the requirement is resistance to an operating environment over about 500°C.

Solution Treatment (Annealing) – heat to 950-1120°C and cool rapidly for maximum corrosion resistance.

Stabilising – heat to 870-900°C for 1 hour per 25mm of thickness and air cool. Stabilisation is recommended for most severe service conditions (above 425°C) and particularly for material annealed at the upper side of the annealing temperature range.

Stress Relief – Heat to 700°C for 1 to 2 hours and air cool. These grades cannot be hardened by thermal treatment.

Our main products: Stainless/Duplex/Nickel Alloy Pipe/Tube:

1>.A:Stainless Steel Grade: TP304/304L/304H, TP310S/310H, TP316/316L/316Ti/316H, TP317L/317LN, TP321/321H, TP347/347H, NO8904(904L),

B:PH Stainless Steel:17-4PH(1.4542), 17-7PH(1.4568),15-7PH(1.4532)

C:Duplex Steel Grade: S31803(2205), S32750(2507), S32760, S32304, S32101, S31254(254Mo), 235Ma, UNS NO8926, NO8367.

D:Nickel Alloy Steel Grade:Hestalloy:C-276, C-4, C-22, C-2000, X, B-2, B-3, G-30, G-35. Monel:400,401, 404, R-405, K500.

Inconel:600, 601, 617, 625, 690, 718, 740, X-750. Incoloy:800, 800H, 800HT, 825, 840.

Pure Nickel:Ni-200, Ni-201, Ni-270. NS Alloy:Ns 1101, NS1102, NS1103,NS3105.

2>.Standards: ASTM A213, A249, A269, A312, A789,A790, B163,B167, B444, B677,... and ASME,DIN, EN, JIS, BS, GOST,...

3>.Out diameter sizes range: 0.5mm~650mm. Wall thickness:0.05mm~60mm. Max. length under 26 meters/PC.

4>.Seamless & welded, Solution Pickling/Bright Annealed / Polished.

Advantage Products: (Boiler & Heat Exchanger & Condenser Tube):

ASTM A213(TP304,TP304L,TP304H,TP310S,TP316L,TP316Ti, TP317/L, TP321/H, TP347/H)

ASTM A249(TP304,TP304L,TP316L, TP321/H)

ASTM A789(S31803(2205), 32750(2507), S31254(254MO),S32304)

ASTM B163/B167/B444 for Nickel Alloy Steel Tube

ASTM B677 UNS NO8904(904L)

ASTM B111(70400, C70600, C71500, C71640, C68700, C44300)

Other Standard: EN10216-5, DIN 17456, DIN17458, GOST9941-81, JIS-G3459, JIS-G3463

Specification:

ASME SA213/A213: Standard Specification for Seamless Ferritic and Austenitic Alloy-

Steel Boiler, Superheater and Stainless Steel Heat Exchanger Tubes.

ASTM A249 / A249M:Standard Specification for Welded Austenitic Steel Boiler, SuperheaterHeat-Exchanger, and Condenser Tubes.

Other Standard:DIN 17456 , DIN 17458, EN10216-5, GOST 9940-81, GOST 9941-81, JIS-G3463,...

Material Grade:

|

American Standard

|

Austenitic Steel:

TP304,TP304L,TP304H, TP304N, TP310S,TP316,TP316L,TP316Ti,TP316H, TP317,TP317L, TP321, TP321H,TP347, TP347H,904L…

Duplex Steel :

S32101,S32205,S31803,S32304,S32750, S32760

Others:TP405,TP409, TP410, TP430, TP439,...

|

|

Europen Standard

|

1.4301,1.4307,1.4948,1.4541,1.4878,1.4550,1.4401,1.4404,1.4571,1.4438, 1.4841,1.4845,1.4539,1.4162, 1.4462, 1.4362, 1.4410, 1.4501

|

|

GOST

|

08Х17Т,08Х13,12Х13,12Х17,15Х25Т,04Х18Н10,08Х20Н14С2, 08Х18Н12Б,10Х17Н13М2Т,10Х23Н18,08Х18Н10,08Х18Н10Т, 08Х18Н12Т,08Х17Н15М3Т,12Х18Н10Т,12Х18Н12Т,12Х18Н9, 17Х18Н9, 08Х22Н6Т, 06ХН28МДТ

|

Size Range:

|

Production

|

Outside Diameter

|

Wall Thickness

|

|

Heat Exchanger Tube

|

6.00mm to 101.6mm

|

0.5mm to 8mm

|

Final Finishing

Solution Annealed & Pickled/Bright Annealed.

Type of Tubes:

U-bend & Straight.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!