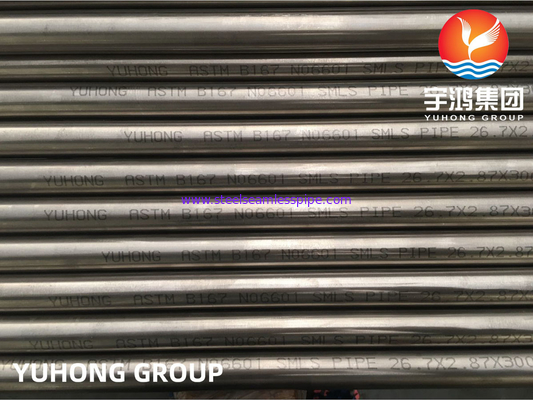

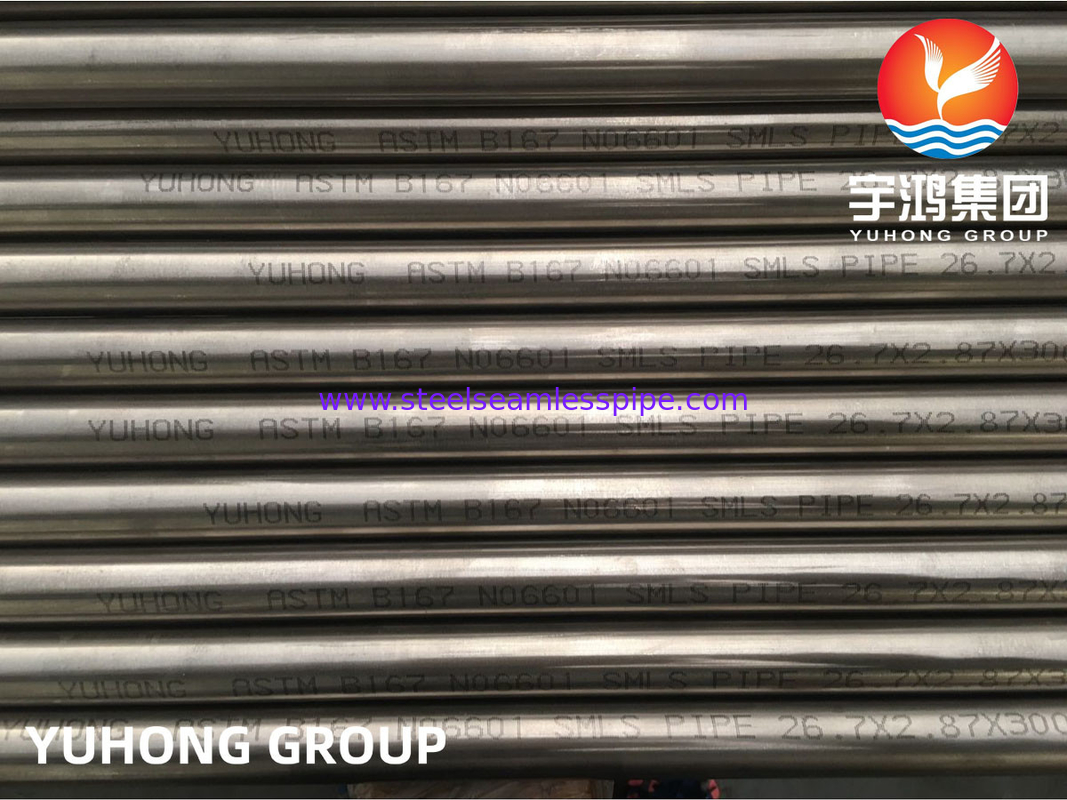

ASTM B167 Inconel 601 N06601 Nickel Alloy Steel Seamless Pipe

What is Inconel 601?

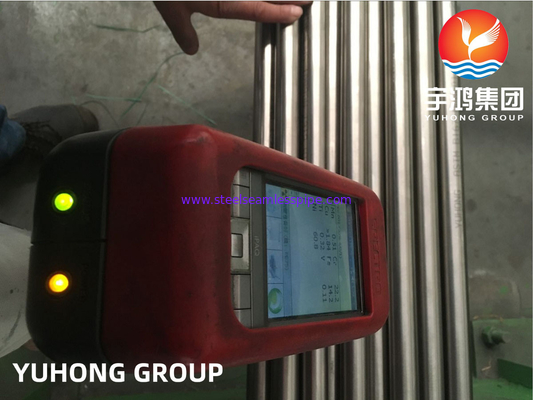

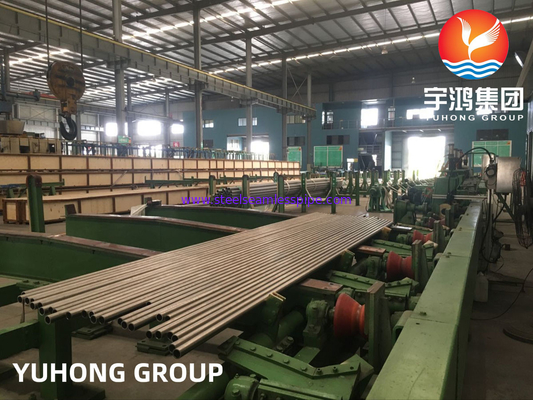

B167 N06601 is a specification for seamless pipes made from Inconel 601, a nickel-chromium alloy known for its high temperature resistance and corrosion resistance. These seamless pipes are typically used in high temperature and corrosive environments, such as in the chemical processing, aerospace, and power generation industries. The seamless construction of these pipes ensures a smooth interior surface, which helps to reduce pressure drop and improve flow efficiency.

This nickel alloy has good high temperature strength, and retains its ductility after long service exposure. It has good resistance to aqueous corrosion, high mechanical strength, and is readily formed, machined and welded.

Inconel 601’s properties make it a material of broad utility in fields like thermal processing, chemical processing, pollution control, aerospace, and power generation. However, alloy 601 is not suggested for use in strongly reducing, sulfur bearing environments.

Processability of Inconel 601 (Alloy 601/UNS N06601)

Inconel 601 (UNS N06601) nickel base alloy is easy to hot work. The heating temperature is 1150 ~ 1200 ℃, and the hot working temperature is 1050 ~ 1200 ℃. The simple processing can be carried out below 850 ℃. Cracking will occur in the temperature range of 650 ~ 850 ℃, please avoid this temperature range for processing.

In order to avoid carbide precipitation, it is suggested to increase the cooling rate in the range of 500 ~ 800 ℃. 601 alloy has excellent cold workability and can be processed as SUS 310S and alloy800.

Chemical Compostion of Inconel 601

| Ni |

Cr |

Al |

C |

Mn |

Si |

Fe |

| 61.5 |

22.5 |

1.4 |

.05 |

.3 |

.2 |

14 |

N06601 is easy to machine and weld, but attention should be paid to temperature control during machining, and the forging temperature is usually between 1100℃ and 1200℃. After forging, heat treatment and surface treatment may be required to improve performance.

Le principal avantage des tubes sans soudure en alliage 601 est leur résistance supérieure à la chaleur, ce qui leur permet d'être utilisés à des températures extrêmes sans se dégrader ni perdre leurs propriétés mécaniques au fil du temps. De plus, ces tubes offrent une excellente résistance à la corrosion due aux solutions acides et alcalines et de bonnes caractéristiques de soudabilité qui les rendent faciles à utiliser lors de l'installation.

De plus, les tubes soudés en Inconel 601 peuvent supporter des pressions plus élevées que les systèmes de tuyaux en acier au carbone ordinaires tout en offrant des performances supérieures sur des périodes prolongées, même lorsqu'ils sont exposés à des environnements agressifs tels que l'eau salée ou les vapeurs d'acide chlorhydrique.

Mechanical Properties of Inconel 601

| Tensile (psi) |

.2% Yield (psi) |

Elongation (%) |

| 80,000 |

30,000 |

35 |

Physical Properties of Inconel 601

| Density |

Melting Range |

Specific Heat |

Curie Temperature |

| lb/inch3 |

Mg/m3 |

°F |

°C |

Btu/lb-°F |

J/kg-°C |

°F |

°C |

| 0.293 |

8.11 |

2480-2571 |

1360-1411 |

0.107 |

448 |

<-320 |

<-196 |

*The mechanical properties of Inconel 601 may vary in different product forms or heat treatment conditions.

Equivalent Material of Inconel 601

| Grade |

Euronorm |

Old British |

GOST |

UNS No |

Japanese JIS |

| AFNOR |

No |

En |

BS |

| Inconel 601 |

NC23FeA |

2.4851 |

NiCr23Fe |

NA 49 |

XH60BT |

N06601 |

NCF 601 |

Applications:

-Exhaust system components

-Piping system

-The solid waste incinerator combustion chamber

-Pipe supports and ash handling part

-Exhaust detoxification system components

-Oxygen to the heater

-Heat exchanger tubes

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!