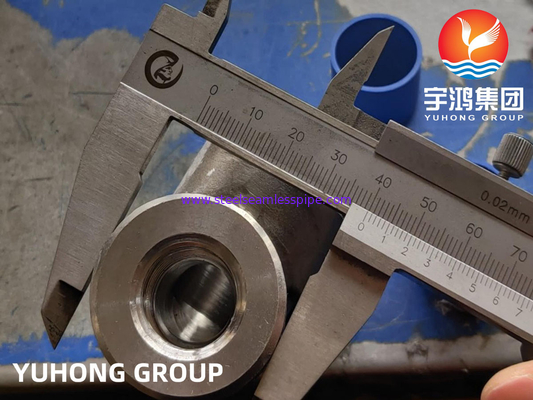

B16.11 Forged ASTM A182 F53 Super Duplex Steel 2507 / S32750 / 1.4410 / F53 Thread Elbow

ASME/ANSI B16.11 covers a wide range of forged fittings, including elbows, tees, crosses, couplings, unions, caps, plugs, bushings, and inserts. These fittings are typically used in piping systems for applications such as oil and gas, refineries, chemical plants, power plants, and other industrial processes. F53 is a super duplex stainless steel grade with excellent corrosion resistance and mechanical properties. Thread Elbow: t has threaded ends to facilitate connection with other threaded components.

ASTM A182 F53 Pipe Fitting Specification

| Grade |

Duplex Steel 2507 / S32750 | WNR. 1.4410 |

| Standard |

ASTM A182 & ASME SA182 |

| Dimensions |

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size |

1/8” NB to 4” NB |

| Grade |

S31803 / S32205 / A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Class |

2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Form |

S/W & SCRD |

| Type |

Elbow, Tee, Union , Cross, CAP, Swage Nipples Coupling, Plug, Bush, Sokolet, Weldoket, Thredolet, Elbolet, Nipolet, Lateral Tee. |

Chemical Composition of A182 F53 Super Duplex Pipe Fittings

| UNS |

C % |

Cr % |

Ni % |

Mo % |

N % |

Mn % |

Cu % |

W |

S |

Si |

| S32750 |

< 0.03 |

24.0-26.0 |

6.0-8.0 |

3.0-5.0 |

0.24-0.32 |

< 1.20 |

< 0.5 |

- |

- |

- |

| 2507 |

< 0.03 |

24.0-26.0 |

6.0-8.0 |

3.0-5.0 |

0.24-0.32 |

< 1.20 |

< 0.5 |

- |

- |

- |

| F53 |

< 0.03 |

24.0-26.0 |

6.0-8.0 |

3.0-5.0 |

0.24-0.32 |

< 1.20 |

< 0.5 |

- |

- |

- |

Mechanical Propertities of A182 F53 Super Duplex Pipe Fittings

| Grade |

YS (MPa) |

UTS (MPa) |

% Elongation |

Hardness(BHN) |

| UNS S32750 |

550 min. |

795 min. |

15 min. |

310 max. |

| 2507 |

550 min. |

795 min. |

15 min. |

310 max. |

| F53 |

550 min. |

795 min. |

15 min. |

310 max. |

Forged Steel Elbow

| Sr. No. |

Material |

Size |

Sch. & Class |

Specification |

Item |

| 1. |

Forged Stainless Steel |

15 NB

To

100 NB |

3000, 6000

&

9000 LBS |

A-182

S/W & SCRD

ANSI B16.11 |

- Elbow - 90o & 45o

- Tee - Equal & Reducing

- Union

- Cross

- Coupling - Full & Half

- Socket Reducing

- CAP

- Plug-Hex & Square

- Nipples (Hex/Reducing)

- Sokolet & Weldolet

- Bush

|

| 2. |

Forged Alloy Steel |

15 NB

To

100 NB |

3000, 6000

&

9000 LBS |

A-182

S/W & SCRD

ANSI B16.11 |

| 3. |

Forged Carbon Steel |

15 NB

To

100 NB |

3000, 6000

&

9000 LBS |

A-105

S/W & SCRD

ANSI B16.11 |

| Stainless Steel in Grade |

ASTM A 182 |

304, 304L, 304H, 316, 316L, 316LN, 316Ti, 309, 310S, 317L, 321, 347, 410, 420, 440C Etc |

| Alloy Steel in Grade |

ASTM A 182 |

F5, F9, F11, F12, F21, F22 & F91. |

| Othe rGrade Available |

A-350 LF2 |

| Other Forms |

Compression Fitting / Instrumentation / Hydraulic Fitting & Also As Per Drawing |

| Other Material like Non Ferrous Metals & Nickel Base Alloys |

Fittings are also available in Copper (Dow), Brass, Aluminium, Cupro Nickel (90/10, 70/30), Hastelloy (C-276), Nickel (200, 201, 205), Monel (K400, K500), Inconel (600, 800), Alloy 20, Duplex, Phosphorus Bronze (90/10, PB2) Etc. as per ASTM, ASME, BS, IS & DIN Standard |

| Test Certificate |

- Manufacturer Test Certificate / Under Third Party Inspection .

- with Excise Gate Pass to avail Modvat benefit.

|

| Product Pictures and Drawings |

|

|

|

|

|

|

|

|

| 90 Degree Elbow (SW) |

45 Degree Elbow (SW) |

Tee (SW) |

Lateral (SW) |

|

|

|

| Cross (SW) |

Socket Weld Fittings |

|

| Socket Weld Dimensional Data |

| 1/8" to 4" class 3000 socket weld, 1/8" to 4" class 6000 socket weld, 1/2" to 2 " class 9000 socket weld |

| Class 3000 |

|

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

1 1/4 |

1 1/2 |

2 |

2 1/2 |

3 |

4 |

| A |

7/8 |

7/8 |

31/32 |

1 1/8 |

1 5/16 |

1 1/2 |

1 3/4 |

2 |

2 3/8 |

3 |

3 3/8 |

4 3/16 |

| B |

29/32 |

29/32 |

1 1/16 |

1 5/16 |

1 9/16 |

1 27/32 |

2 7/32 |

2 1/2 |

3 1/32 |

3 11/16 |

4 5/16 |

5 3/4 |

| C |

0.420 |

0.555 |

0.690 |

0.855 |

1.065 |

1.330 |

1.675 |

1.915 |

2.406 |

2.906 |

3.535 |

4.545 |

| D |

3/8 |

3/8 |

3/8 |

3/8 |

1/2 |

1/2 |

1/2 |

1/2 |

5/8 |

5/8 |

5/8 |

3/4 |

| E |

7/16 |

7/16 |

17/32 |

5/8 |

3/4 |

7/8 |

1 1/16 |

1 1/4 |

1 1/2 |

1 5/8 |

2 1/4 |

2 5/8 |

| Class 6000 |

|

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

1 1/4 |

1 1/2 |

2 |

2 1/2 |

3 |

4 |

| A |

- |

- |

- |

1 5/16 |

1 1/2 |

1 3/4 |

2 |

2 3/8 |

2 1/2 |

3 1/4 |

3 3/4 |

4 1/2 |

| B |

- |

- |

- |

1 9/16 |

1 27/32 |

2 7/32 |

2 1/2 |

3 1/32 |

3 11/32 |

4 |

4 3/4 |

6 |

| C |

- |

- |

- |

0.855 |

1.065 |

1.330 |

1.675 |

1.915 |

2.406 |

2.906 |

3.535 |

4.545 |

| D |

- |

- |

- |

3/8 |

1/2 |

1/2 |

1/2 |

1/2 |

5/8 |

5/8 |

5/8 |

3/4 |

| E |

- |

- |

- |

3/4 |

7/8 |

1 1/16 |

1 1/4 |

1 1/2 |

1 5/8 |

2 1/4 |

2 1/2 |

2 3/4 |

| Class 9000 |

|

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

1 1/4 |

1 1/2 |

2 |

2 1/2 |

3 |

4 |

| A |

- |

- |

- |

1 1/2 |

1 3/4 |

2 |

2 3/8 |

2 1/2 |

3 |

- |

- |

- |

| B |

- |

- |

- |

1 27/32 |

2 7/32 |

2 1/2 |

3 1/32 |

3 11/32 |

3 11/16 |

- |

- |

- |

| C |

- |

- |

- |

0.855 |

1.065 |

1.330 |

1.675 |

1.915 |

2.406 |

- |

- |

- |

| D |

- |

- |

- |

3/8 |

1/2 |

1/2 |

1/2 |

1/2 |

5/8 |

- |

- |

- |

| E |

- |

- |

- |

1 |

1 1/8 |

1 1/4 |

1 3/8 |

1 1/2 |

2 1/8 |

- |

- |

- |

|

ASME/ANSI B16.5 - 1996 - Pipe Flanges and Flanged Fittings

The ASME B16.5 - 1996 Pipe Flanges and Flange Fittings standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking, testing, and methods of designating openings for pipe flanges and flanged fittings.

The standard includes flanges with rating class designations 150, 300, 400, 600, 900, 1500, and 2500 in sizes NPS 1/2 through NPS 24, with requirements given in both metric and U.S units. The Standard is limited to flanges and flanged fittings made from cast or forged materials, and blind flanges and certain reducing flanges made from cast, forged, or plate materials. Also included in this Standard are requirements and recommendations regarding flange bolting, flange gaskets, and flange joints.

ASME/ANSI B16.9 - 2001 - Factory-Made Wrought Steel Buttwelding Fittings

This Standard covers overall dimensions, tolerances, ratings, testing, and markings for wrought factory-made buttwelding fittings in sizes NPS 1/2 through 48 (DN 15 through 1200).

ASME/ANSI B16.11 - 2001 - Forged Steel Fittings, Socket-Welding and Threaded

This Standard covers ratings, dimensions, tolerances, marking and material requirements for forged fittings, both socket-welding and threaded.

Applications

- Oil and gas industry.

- Petrochemical industries ( polymerization reactor cycle pumps and pipework)

- Offshore platforms (heat exchangers, process and service water systems, fire-fighting systems, and injection and ballast water systems)

- Chemical process industries (heat exchangers and vessels)

- Desalination plants (high pressure RO-plant and seawater piping)

- Fertilizers (Recirculation tanks, sedimentation tanks, phosphate reactor recirculation pumps)

- Power industry FGD systems

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!