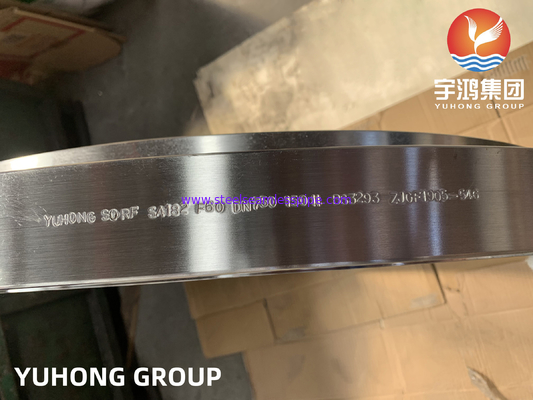

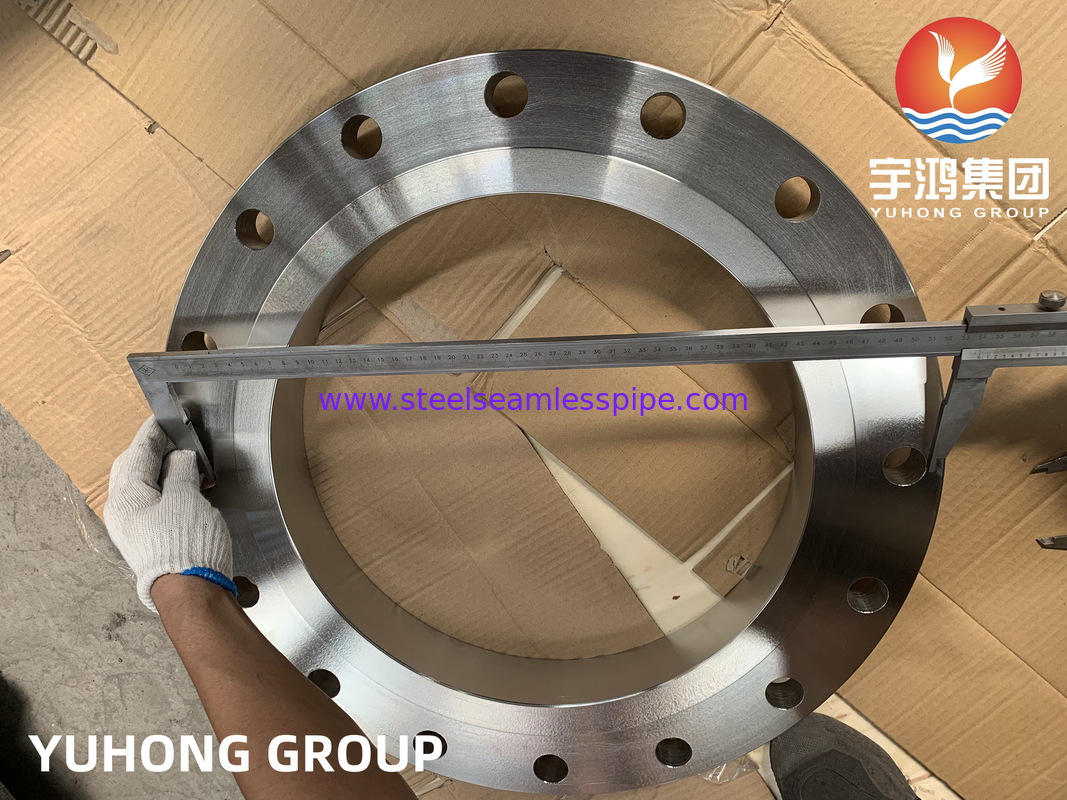

Duplex Steel Flange ASTM A182 F60 UNS S32205 B16.5 Chemical Processing

Overview

ASTM A182 Grade F60 is a standard forged grade of duplex stainless steel. It has the same nominal composition of 22Cr-5Ni-3Mo-N as ASTM A182 Gr. F51, but the actual composition is more narrowly restricted. Both Gr. F51 and Gr. However, the UNS number for the former is S31803 and the UNS number for the latter is S32205. The composition range originally set for alloy 2205 (S31803) was too wide. Experience has shown that for optimum corrosion resistance and to avoid intermetallic phases, the content of chromium, molybdenum and nitrogen should be kept at the higher half of the S31803 range. Therefore, a modified 2205 with a narrower composition range was introduced with the UNS number S32205.

What is the difference between F60(UNS S32205) and F51 (UNS S31803)?

Modern duplexes appeared in the early 1980s, and the original duplex specification was named UNS S31803.This remains the most widely used duplex grade.UNS S31803's inherently attractive combination of properties makes it suitable for a wide range of demanding applications.

Commonly used equivalent names for this stainless steel are:

F51: According to ASTM A182 ("Standard Specification for Pipe Flanges, Forged Fittings, Valves, and Components of Alloys and Stainless Steels, Forged or Rolled, for High-Temperature Service"), the "F" prefix stands for forged products. Duplex steels are numbered between F50 and F71.

1.4462: is the EN numerical designation (werkstoffnummer) of the material. X2CrNiMoN22-5-3 is the EN chemical designation.

To learn more about the different names in stainless steel, read this article.

Chemical composition of UNS S31803, %:

An important characteristic of this material is its excellent resistance to pitting corrosion. This is a form of corrosion that produces cavities in surfaces, usually in chloride-containing environments.

A method of comparing susceptibility to this type of corrosion is the PREN formula, which represents the pitting resistance equivalent number. The chromium, molybdenum and nitrogen content determines the resistance: PREN = %Cr + 3.3 x %Mo + 16 x %N

The difference in PREN between the bottom and top of the chemical specification is:

21 + (3,3 x 2,5) + (16 x 0,08) = 28,08

Vs.

23 + (3,3 x 3,5) + (16 x 0,2) = 37,75

In order to minimize pitting corrosion of UNS S31803, manufacturers are producing this grade to the upper limit of the permissible specification. After this, a new specification called UNS S32205 or F60 was introduced according to ASTM A182, which was designed to differentiate between double-chained bodies produced at the top of the composition.

Chemical composition of UNS S32205, %:

The minimum PREN for this stainless steel is 34,14. therefore, duplexes made according to UNS S32205 are interchangeable with UNS S31803, but not vice versa.

For more demanding applications, especially offshore oil and gas production, super duplexes (PREN range 38 - 45) and even ultra duplexes (PREN range >45) have been developed. For less demanding applications, low duplex steels (PREN range 22 - 27) are used.

Chemical Composition of ASTM A182 F60 UNS S32205 Flanges

| Element |

Composition, % |

| C |

≤0.030 |

| Mn |

≤2.00 |

| P |

≤0.030 |

| S |

≤0.020 |

| Si |

≤1.00 |

| Ni |

4.5–6.5 |

| Cr |

22.0–23.0 |

| Mo |

3.0–3.5 |

| N |

0.14–0.20 |

Mechanical Properties of ASTM A182 F60 UNS S32205 Flanges

| Density |

Melting Point |

Yield Strength (0.2%Offset) |

Tensile Strength |

Elongation |

| 7.8 g/cm3 |

(2460 °F) 1350 °C |

MPa - 550, Psi - 80000 |

MPa - 800, Psi - 116000 |

15 % |

Equivalent Grades

|

PIPE STANDARD

|

WERKSTOFF NR.

|

UNS

|

|

UNS S32205 Pipe

|

1.4462

|

S32205

|

Application

Oil and gas exploration and production

Nuclear Power Plant

Petrochemical

Seawater cooling

Chemical Processing

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!