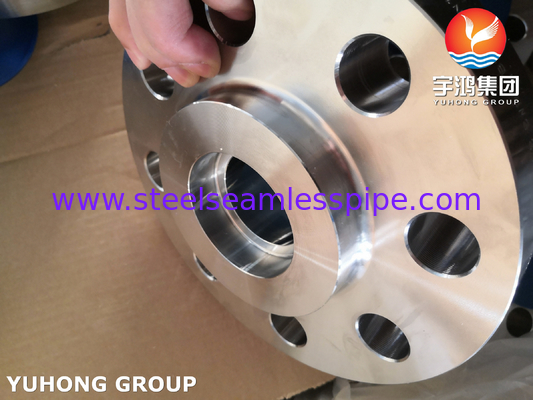

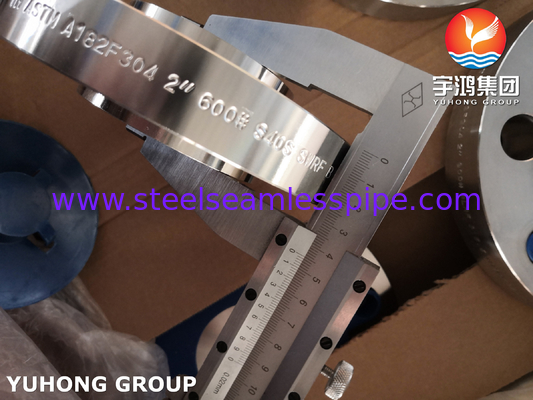

SWRF Stainless Steel Flange ASTM A182 F304 B16.5 Oil Gas Proof Against Corrosion

What is ASTM A183 F304 Flange?

ASTM A182 F304 is Stainless Steel Flat Welding Flanges are made of stainless steel 304 as raw material, through the processes of forging, turning, polishing, inspection, etc., and manufactured into a kind of piping fittings, which are usually used for connecting pipelines and equipments in order to transmit fluids in piping systems. Here we come to know more about the production process and material standard requirements of this flange.

First, the production process:

1, material cutting: according to ASME B16.9 feet standard requirements, select the appropriate size of the raw material for cutting down. Common cutting methods include shearing, flame cutting, plasma cutting and so on. When cutting, you need to pay attention to keep the cutting surface flat and accurate.

2, forging: F304 stainless steel material is heated to a certain temperature and then forged to form the basic shape and size of the flange.

3,Turning:Turning the flange after forging to precisely control its diameter and thickness and other dimensions.

4,Finishing: The flange after turning is polished to remove surface burrs and oxidized layer to ensure the surface of the flange is flat and smooth.

5,Inspection: Strict inspection and testing of the polished flange to ensure that its dimensional accuracy, surface quality and sealing performance meet the requirements.

Feature of ASTM A182 F304

1.Corrosion resistance,

2.high pressure resistance,

3.impermeability,

4.smooth inner surface,

5.low cost,

6.long life and easy installation.

Chemical Composition of A182 F304 Alloy Steel Flanges

| |

C |

Mn |

Si |

P |

S |

Cr |

Ni |

N |

| 304 |

0.07max |

2.0max |

0.75max |

0.045max |

0.03max |

min: 18.0 max: 20.0 |

min: 8.0 max: 10.5 |

— |

Mechanical Properties of A182 F304 Alloy Steel Flanges

| Grade |

Tensile Strength (MPa) min |

Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) min |

Hardness |

| Rockwell B (HR B) max |

Brinell (HB) max |

| 304 |

515 |

205 |

40 |

92 |

201 |

Physical Composition of A182 F304 Alloy Steel Flanges

| Grade |

Density(kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (μm/m/°C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-100°C (J/kg.K) |

Electrical Resistivity (nΩ.m) |

| 0-100°C |

0-315°C |

0-538°C |

at 100°C |

at 500°C |

| 304/L/H |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |

Food and pharmaceutical industry

Petroleum

Energy

Chemical

Oil Gas

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!