Carbon Steel Butt Weld Fittings B16.9 ASTM A234 WPB Oil Gas Heat Exchanger Valve

Overwiew

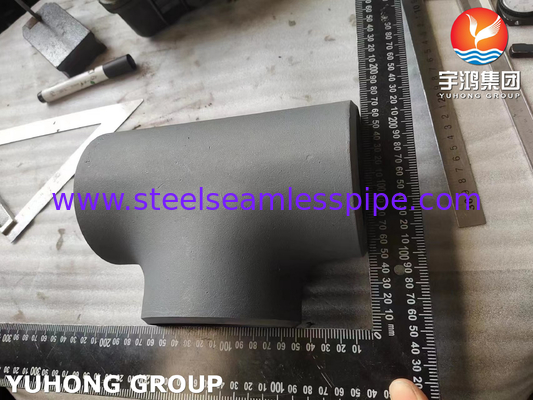

Tee fittings are also known as tee fittings or three-way fittings. A tee fitting is used for the main pipe. It has three vacancies, i.e. one inlet, two outlets; or two inlets, one outlet. It is a kind of chemical piping fittings. It has T-shape, Y-shape, equal pipe holes and reducer holes. It can be used to change the flow direction of fluids, and can also be used in pipes, ducts and pipelines of various liquid chemical materials. It is mainly used in medical, water conservancy (water-saving irrigation, water supply and drainage), energy (oil, gas, nuclear industry), construction and other engineering fields.

Characteristic of ASTM A234 WPB TEE

Carbon steel tee fittings are generally used for regulating valve devices with drainage. Concentric round pipe is conducive to fluid flow, change the diameter of the fluid flow pattern of less interference.

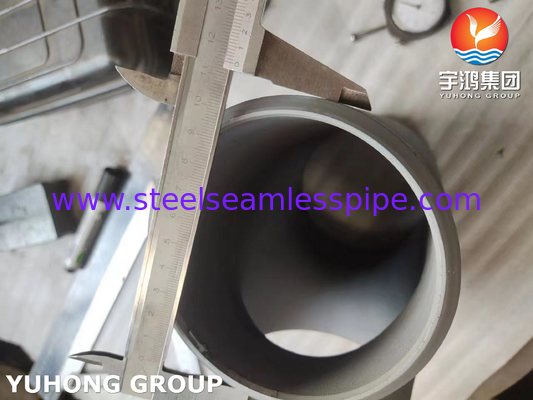

Therefore, seamless tee fittings use concentric different diameter pipes for gas and vertical flow liquid piping. As one side of the different diameter pipe is flat, which is conducive to draining or discharging the liquid, easy to start and maintain, so the liquid pipe of the horizontal device is generally used for the different diameter pipe.

Different diameters of the pipe, also known as the size of the head, the two ends of the orifice diameter is different, used to connect the different diameters of the pipe fittings or flanges for diameter changes. In the concentric and different diameter pipe ends, the center of the circle in the same axis, when the pipe diameter change, if the axis to calculate the orientation of the pipe, the azimuth angle of the pipe will remain unchanged, which is usually used to change the diameter of the gas or vertical liquid pipe. Circumferential cuts at the ends of different pipe diameters pain pipes are generally used for horizontal liquid pipes.

Butt-welding tee fittings are elbows made of steel hot-pressed or forged, and are connected by welding tee fittings directly to the steel pipe. The main manufacturing technical indexes of butt-welding tee fittings are GB/T 12459, GB/T 13401, ASMEB 16.9, SH 3408, SH3409, HG/T21635, HG/T21631, SY/T0510.

Welded tee fittings generally have equal diameter tee fittings, reducer tee fittings, etc. The materials are carbon steel, alloy steel and stainless steel.

When the chromium content in steel reaches about 1.2%. The oxygen effect in the corrosive medium forms a very thin oxide film (self-passivation film) on the steel surface. Seamless tee fittings can prevent further corrosion of the steel matrix, in addition to chromium, the commonly used alloying elements are nickel, molybdenum, titanium, niobium, copper, nitrogen, etc., to meet the requirements of concentric reducers for various purposes of structure and function. In the production of concentric reducer pipe, choose a certain production process to ensure that the outstanding effect and role in the production and processing.

Chemical Composition of ASTM A234 WPB TEE

| Grade |

C |

Mn |

P |

S |

Si |

Cr |

Mo |

Ni |

Cu |

V |

Nb |

| WPB |

0.3 |

0.29-1.06 |

0.05 |

0.058 |

0.1min |

0.4 |

0.15 |

0.4 |

0.4 |

0.08 |

0.02 |

Mechanical Properties of ASTM A234 WPB TEE

| Tensile Requirements |

WPB |

WPC, WP11CL2 |

WP11CL1 |

WP11CL3 |

| Tensile Strength, min, ksi[MPa] |

60-85 |

70-95 |

60-85 |

75-100 |

| (0.2% offset or 0.5% extension-under-load) |

[415-585] |

[485-655] |

[415-585] |

[520-690] |

| Yield Strength, min, ksi[MPa] |

32 |

40 |

30 |

45 |

| [240] |

[275] |

[205] |

[310]

|

Equivalent of ASTM A234 WPB TEE

| Pipe |

Pipe Tee Fitting |

Flanges |

Valves |

Bolts & Nuts |

| A106 Gr A |

A234 Gr WPA tee |

A105 |

A216 Gr WCB |

A193 Gr B7

A194 Gr 2H |

| A106 Gr B |

ASTM A234 gr WPB tee |

A105 |

A216 Gr WCB |

| A106 Gr C |

A234 Gr WPC tee |

A105 |

A216 Gr WCB

|

Application

Oil Gas

Heat Exchanger

Valve

pipe branch

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!