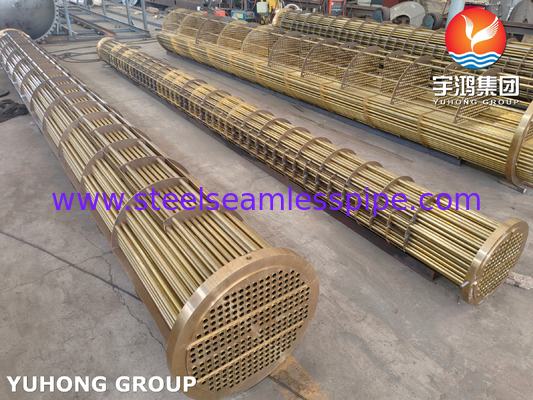

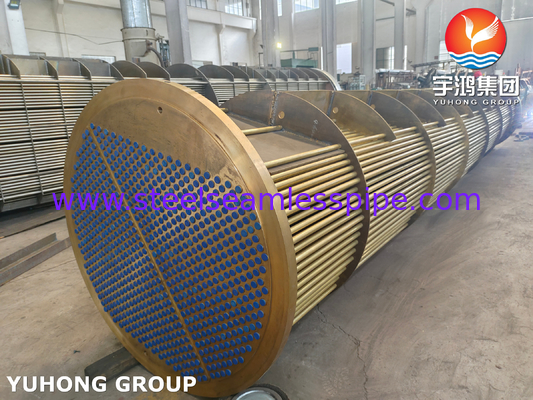

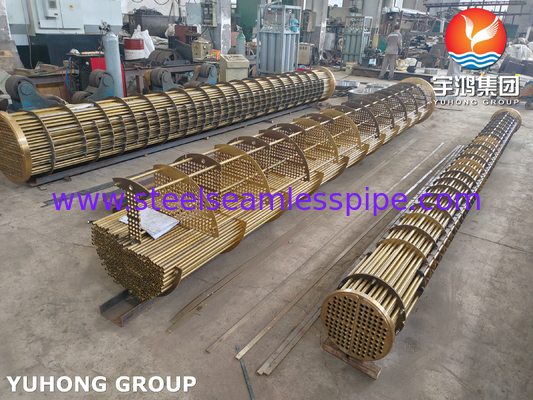

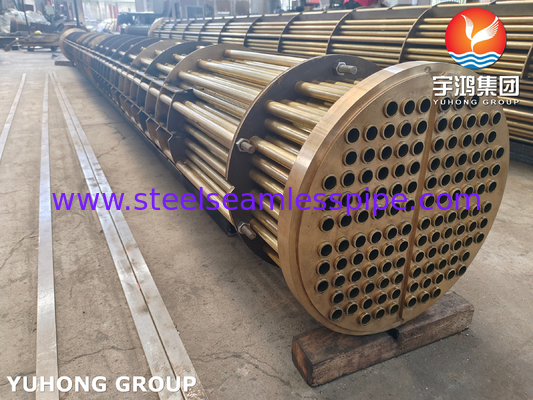

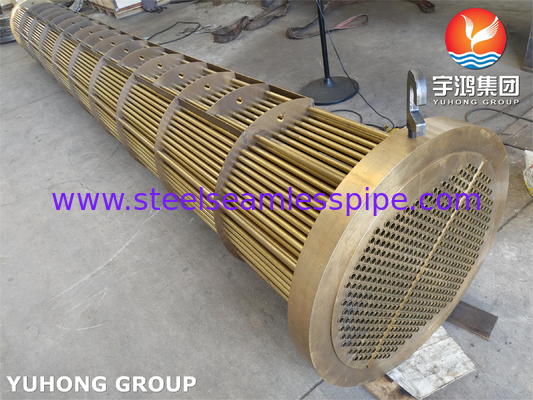

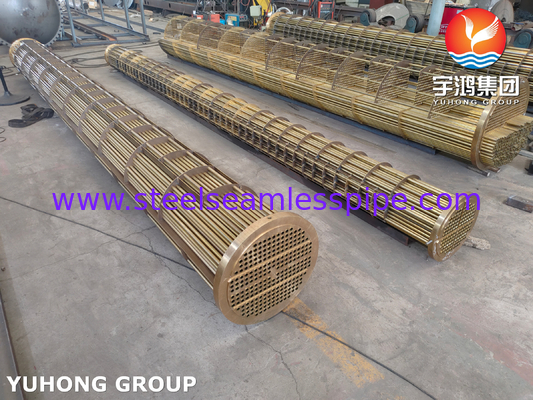

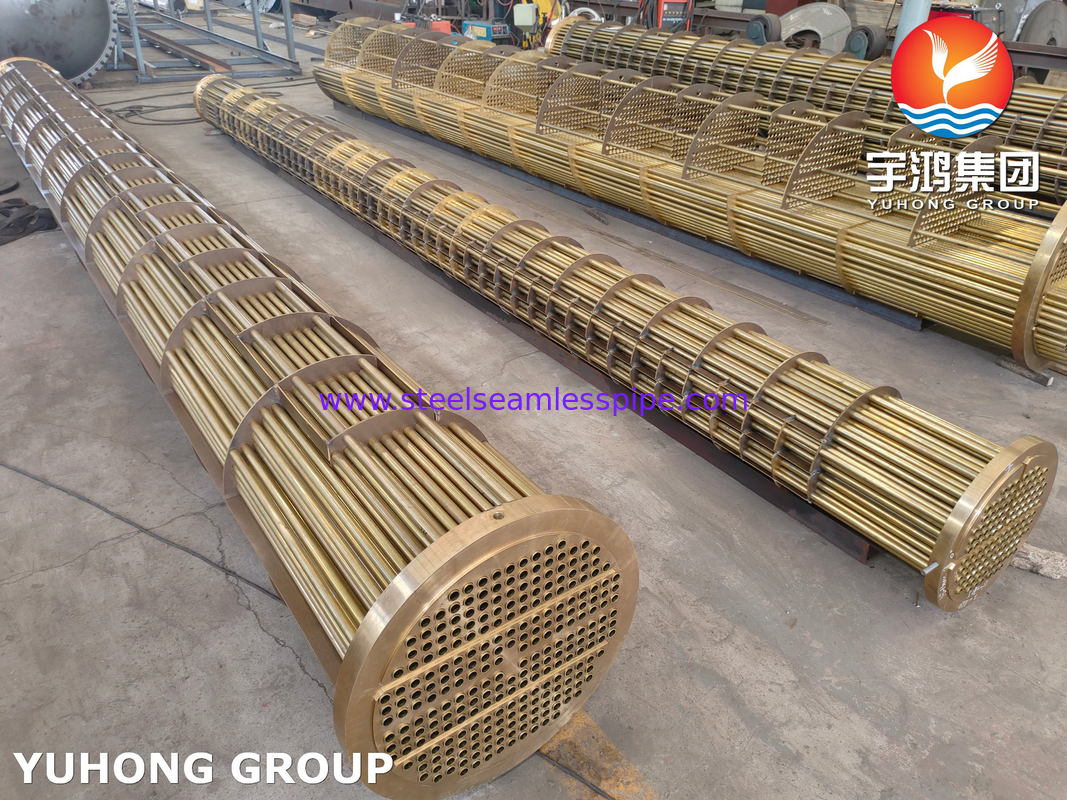

Copper Alloy Steel Straight Tube Bundle Heat Exchanger Parts

Tube bundle heat exchanger is a typical heat exchanging device that make two liquid with different temperatures to exchange heat. Through the heat exchanger tank, one fluid can be cooled down and the other fluid can be heated to meet the required temperature.

The tube bundle can contain different types of tubes, such as tubes with vertical fins and plain tubes. These tubes can be placed in different configurations such as Floating head configuration, fixed tube configuration, and U-shaped tube configuration.

The first of the most common tube bundle configurations is the straight line type. This layout consists of straight tubes which open on either end of the bundle into entry and exit chambers which form the end caps of the shell. The hot material is then pumped through the bundle in a straight line from one end of the shell to the other.

The second common tube bundle configuration is the U tube layout. This bundle variant features entry and exit points on the same side of the shell on a tube shell cap divided into two sealed chambers. The tubes leave the entry chamber and travel to the opposite end of the shell where they make a U bend and return in the opposite direction to the exit chamber.

How thick is a tube bundle?

between 5/8” to 3”

Tubesheet Thickness can vary between 5/8” to 3” in thickness. The thickness you require will depend on the use and volume of the tube bundle. Tubesheet Diameter will always be larger than the diameter of the bundle itself.

Why Use a Tube Bundle?

U bend tube designs also allow for the tube bundles easily removed from the heat exchanger. This is helpful in inspection and cleaning of the shell and outside of the tube bundle.

1. Tube Bundle with high heat efficient

The heat efficiency is one of the most major reasons for actually using heat exchangers. With the help of a tube bundle, the efficiency of heat tends to increase by a long shot, which makes the overall process much more productive and fully fulfills the requirements in the overall procedure of heat transfer.

2. Tube Bundle is easy to Install

It is simpler to install tube bundles than other types tube cores. Most of the installation has to be done underground. While in some case of the shell and heat exchanger, the installation has to be done inside the shell, which is a much more congested area. The simplicity of tube bundles is that they are not twisted but,are made by straight tubes, which design makes their replacement much easier.

3. How to choose tubing materials

Most tubing companies order a number of different materials for creating tube bundles. Manufacturers realize that different consumers of tube bundles require different,types of materials for their tubes. Thus. they can choose tube bundle made up of carbon steel or stainless steel. In the case of high heat transfer, they may use copper or copper alloys.

Applications:

-Aerospace

-Compressor Cooling

-Food & Beverage

-Healthcare

-HVAC

-Industrial

-Marine Applications

-Metals & Mining

-Oil & Gas

-Petrochemical (processing and refining)

-Pharmaceuticals

-Power Generation

-Pulp & Paper

-Refrigeration

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!