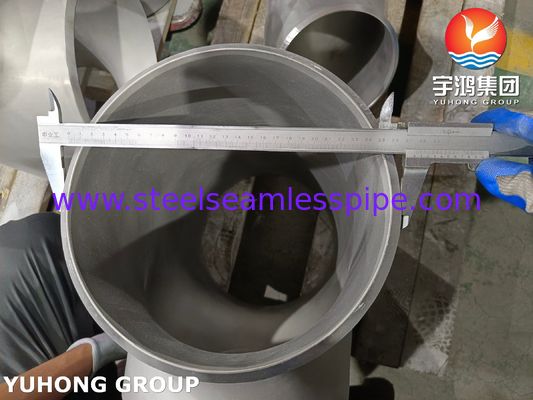

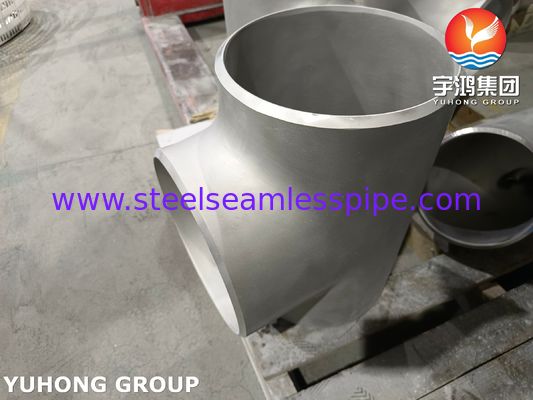

ASTM A815 S31803 Duplex Stainless Steel Fitting Tee B16.9

ASTM A815, the American Society for Testing and Materials (ASTM) standard for "Standard Specification for Wrought Ferritic, Ferritic/Austenitic, and Martensitic Stainless Steel Pipe Fittings," covers the manufacturing requirements for various stainless steel butt-weld, socket-weld, and threaded fittings. S31803 is known as duplex stainless steel due to its microstructure consisting of approximately 50% ferrite and 50% austenite, more commonly known commercially as 2205 duplex. Its improved version, S32205, has slightly different chemical compositions, but similar properties and applications, with S32205 offering superior corrosion resistance.

ASTM A815 S31803 butt-weld fittings are typically manufactured from forged or stamped steel plates/billets, followed by machining. All ASTM A815 S31805 duplex steel fittings undergo a solution annealing treatment, which involves heating to a minimum temperature of approximately 1020°C to 1100°C, then holding at this temperature for a sufficient time to dissolve the detrimental phases, followed by a rapid water quench. This treatment achieves the desired duplex microstructure, ensuring optimal corrosion resistance and mechanical properties, and relieving processing stresses.

What are the core advantages of ASTM A815 S31803 Duplex Stainless Steel?

1. High Strength: The yield strength of S31803 is approximately twice that of standard austenitic stainless steels such as 304 and 316. This higher yield strength allows S31803 duplex steel pipe fittings to be designed and manufactured with thinner walls and lighter weight at the same design pressure, reducing production costs and improving economic benefits.

2. Excellent Stress Corrosion Cracking Resistance: One of the most prominent advantages of ASTM A815 S31803 is its strong resistance to chloride stress corrosion cracking, maintaining excellent mechanical properties even in chloride-containing environments. For stainless steels such as 304 and 316, stress corrosion cracking is the primary cause of their failure in chloride-containing environments.

3. Good Corrosion Resistance: ASTM A815 S31803 duplex stainless steel offers uniform corrosion resistance close to, or even better than, 316L stainless steel. Thanks to its high content of chromium, molybdenum, and nitrogen, S31803 boasts an extremely high pitting corrosion resistance equivalent, significantly outperforming 316L and approaching that of 904L. Furthermore, the presence of approximately 50% ferrite provides S31803 with excellent wear resistance and enhanced corrosion fatigue resistance.

4. Good Weldability: S31803 duplex steel exhibits excellent weldability, but the welding process and heat input must be carefully controlled to maintain a balance between ferrite and austenite in the weld and heat-affected zone, preventing the precipitation of harmful intermetallic phases.

ASTM A815 S31803 Duplex Stainless Steel Chemical Components

| Grade |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

N |

| S31803 |

≤0.030 |

≤2.00 |

≤0.030 |

≤0.020 |

≤1.00 |

21.0-23.0 |

4.5-6.5 |

2.5-3.5 |

0.08-0.20 |

ASTM A815 S31803 Duplex Stainless Steel Fittings Main Application

- Oil and Gas Industry: Offshore platform process piping, subsea pipelines, heat exchangers, and oil and gas processing equipment.

- Chemical and Petrochemical Industry: Various towers, reactors, heat exchangers, and piping systems, especially in environments containing chlorides and acidic media.

- Chemical and Oil and Gas Transportation: Ship cargo tanks and piping systems.

- Pulp and Paper Industry: Digesters and bleaching plants.

- Energy and Environmental Protection: Flue gas desulfurization systems, seawater cooling piping, and wastewater treatment systems.

- High-Pressure and Highly Corrosive Media: Any piping system requiring both high mechanical strength and excellent corrosion resistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!