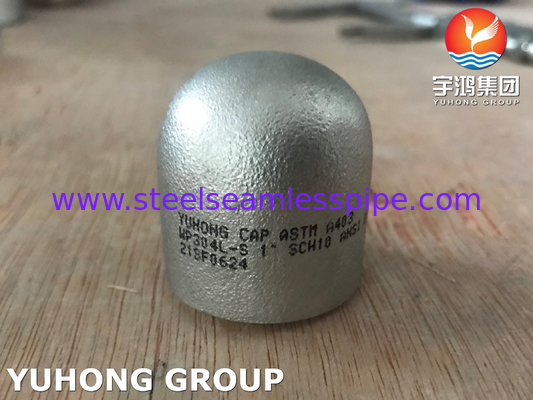

ASTM A403 WP304L 1.4307 End Cap Stainless Steel Buttweld Fitting

Overview:

WP304L end caps are critical components used in various piping systems, particularly in industries where corrosion resistance and durability are essential. Made from WP304L stainless steel, these end caps are designed to provide a secure closure at the end of pipes, preventing the escape of fluids and ensuring structural integrity.

The “304L” designation indicates that this alloy has a lower carbon content compared to standard 304 stainless steel, enhancing its weldability and reducing the risk of carbide precipitation during welding. This makes WP304L suitable for high-temperature applications and environments exposed to corrosive substances.

These end caps offer excellent resistance to oxidation and corrosion, making them ideal for use in chemical processing, food and beverage, pharmaceutical, and marine applications. The material is also non-magnetic and exhibits good strength and ductility, contributing to its versatility in different conditions.

Manufactured through processes like hot or cold working, these end caps come in various sizes and wall thicknesses to accommodate different piping needs. They can be used in both welded and threaded connections, ensuring a tight fit in various installation scenarios. Additionally, WP304L end caps comply with industry standards, ensuring quality and reliability.

In terms of maintenance, these caps require minimal care due to their robust nature, although regular inspections can help identify any signs of wear or corrosion over time. Their longevity and durability not only reduce the need for frequent replacements but also contribute to the overall efficiency and safety of the piping system.

Specification:

| Standard |

ASTM A403/ASME SA403 |

| Material |

WP304L; 1.4307 |

| Type |

Buttweld Cap |

| Connection |

Welding |

| Size |

1/2"-48"(DN15-DN1200) or custom size |

| Thickness |

SCH10S-XXS(2-60mm) |

| Surface |

Sand Blasting |

| Packing |

Plywood case/Pallet |

Chemical Composition:

| Grade |

C |

Mn |

P |

S |

Si |

Ni |

Cr |

| WP304L |

0.03 max |

2.0 max |

0.045 max |

0.03 max |

1.00 max |

8.0-12.0 |

18.0-20.0 |

Mechanical Properties:

| Grade |

Yield Strength, min,

ksi [MPa] |

Tensile Strength, min,

ksi [MPa] |

Elongation

%

|

| WP304L |

25(170) |

70(485) |

28 |

Dimension for BW Cap:

|

| Nominal Size |

Out Diameter at Bevel

(mm)

|

Length

(mm)

|

Limiting Wall Thickness for Length E

(mm)

|

| DN |

NPS |

O.D. |

E |

E1 |

| 15 |

1/2 |

21.3 |

25 |

25 |

4.57 |

| 20 |

3/4 |

26.7 |

25 |

25 |

3.81 |

| 25 |

1 |

33.4 |

38 |

38 |

4.57 |

| 32 |

1 1/4 |

42.2 |

38 |

38 |

4.83 |

| 40 |

1 1/2 |

48.3 |

38 |

38 |

5.08 |

| 50 |

2 |

60.3 |

38 |

44 |

5.59 |

| 65 |

2 1/2 |

73.0 |

38 |

51 |

7.11 |

| 80 |

3 |

88.9 |

51 |

64 |

7.62 |

| 90 |

3 1/2 |

101.6 |

64 |

76 |

8.13 |

| 100 |

4 |

114.3 |

64 |

76 |

8.64 |

| 125 |

5 |

141.3 |

76 |

89 |

9.65 |

| 150 |

6 |

168.3 |

89 |

102 |

10.92 |

| 200 |

8 |

219.1 |

102 |

127 |

12.7 |

| 250 |

10 |

273.0 |

127 |

152 |

12.7 |

| 300 |

12 |

323.8 |

152 |

178 |

12.7 |

| 350 |

14 |

355.6 |

165 |

191 |

12.7 |

| 400 |

16 |

406.4 |

178 |

203 |

12.7 |

| 450 |

18 |

457.0 |

203 |

229 |

12.7 |

| 500 |

20 |

508.0 |

229 |

254 |

12.7 |

| 550 |

22 |

559.0 |

254 |

254 |

12.7 |

| 600 |

24 |

610.0 |

267 |

305 |

12.7 |

| 650 |

26 |

660.0 |

267 |

... |

... |

| 700 |

28 |

711.0 |

267 |

... |

... |

| 750 |

30 |

762.0 |

267 |

... |

... |

| 800 |

32 |

813.0 |

267 |

... |

... |

| 850 |

34 |

864.0 |

267 |

... |

... |

| 900 |

36 |

914.0 |

267 |

... |

... |

| 950 |

38 |

965.0 |

305 |

... |

... |

| 1000 |

40 |

1016.0 |

305 |

... |

... |

| 1050 |

42 |

1067.0 |

305 |

... |

... |

| 1100 |

44 |

1118.0 |

343 |

... |

... |

| 1150 |

46 |

1168.0 |

343 |

... |

... |

| 1200 |

48 |

1219.0 |

343 |

... |

... |

GENERAL NOTE: The shape of these caps shall be ellipsoidal and shall conform to the requirements given in the ASME Boiler and Pressure Vessel Code.

NOTES:

(1) Length E applies for thickness not exceeding that given in column “Limiting Wall Thickness for Length, E.”

(2) Length E1 applies for thickness greater than that given in column “Limiting Wall Thickness for Length, E” for NPS 24 and smaller. For NPS 26 and larger, length E1 shall be by agreement between the manufacturer and purchaser. |

Application:

1. Piping Systems: Used to seal the ends of pipes in chemical, oil, and gas industries, ensuring integrity and preventing leaks.

2. Food Processing: Suitable for food handling and processing systems, where hygiene and corrosion resistance are critical.

3. Pharmaceutical Industry: Utilized in manufacturing processes where cleanliness and low nickel content are essential to prevent allergic reactions.

4. Brewery Equipment: Ideal for brewing systems, where it helps maintain the quality of beer.

5. Marine Applications: Used in marine environments due to its resistance to saltwater corrosion.

6. Construction: Applications in structural components that require durability and resistance to the elements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!