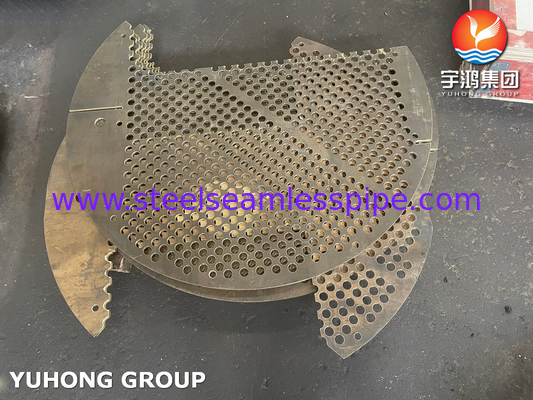

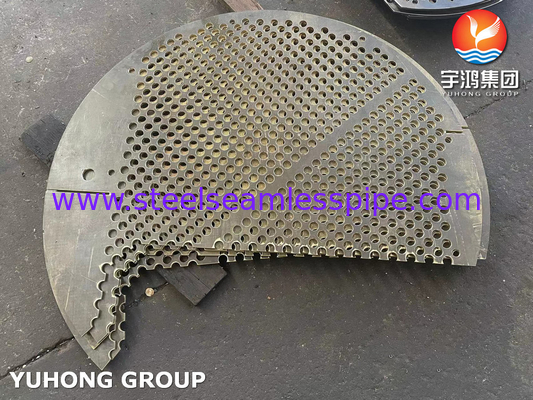

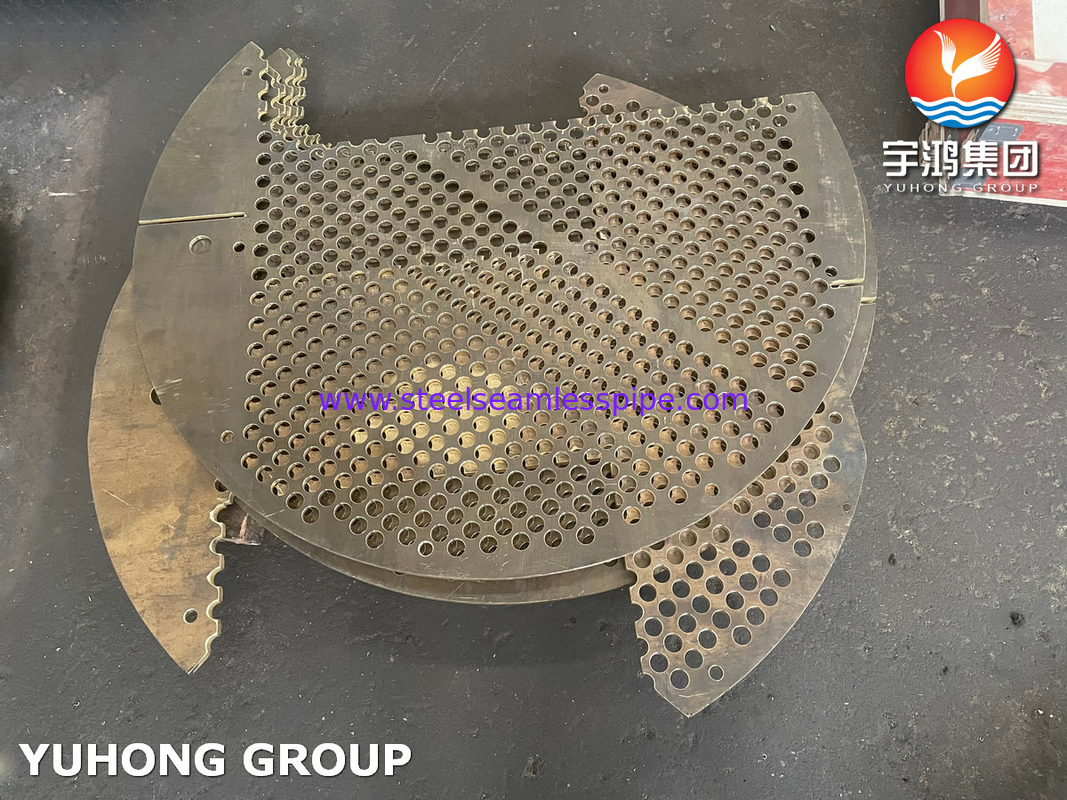

| Baffle plate for Heat Exchanger(Plate Type) |

| Type of materials |

Technical requirements |

| Or according to customer requirement |

| Duplex Stainless Steel |

ASTM/ASME SA240 S32205, S31803, S332750, S32760, S31254, S31500, S32304,… |

| Austenitic Stainless Steel |

ASTM/ASME SA240 SS304, SS304L, SS310S,SS310H, SS316, SS316L, SS317, SS317L |

| ASTM/ASME SA240 SS321, SS321H, SS347, SS347H, SS904L |

| Carbon Steel |

ASTM/ASME SA283 / SA285/ SA299 Gr.A, Gr.B, Gr.C , Gr.D |

| ASTM/ASME SA516 Gr.55, Gr.60, Gr.65, Gr.70 |

| Alloy Steel |

ASTM/ASME SA387 Gr.2, Gr.11,Gr.12,Gr.21, Gr.22, Gr5, Gr.9, Gr.91 |

| Non Ferrous |

Titanium, Brass, Al-Brass, Copper Nickel, Nickel Alloys, Hastelloy |

| Titanium |

ASTM/ASME SB265 Gr.1, Gr.2, Gr.5, Gr.7,Gr.9 Gr.12, Gr.16 |

| Copper Alloy |

ASTM/ASME SB171 C44300, C46400,C63000,C70600(Cu-Ni 90/10), C71500(Cu-Ni 70/30) |

| ASTM/ASME SB127 Monel400 |

| Copper |

ASTM/ASME SB152 UNS C10100, C10200,C10300,C10800,C12200 |

| Aluminum Bronze |

ASTM/ASME SB169 C61300,C61400 |

| Nickel Alloys |

ASTM/ASME SB168 UNS N06600, N06601, N06603, N06690,

N06693, N06025, N06045, AND N06696,UNS N06617, |

| ASTM/ASME SB333 UNS N10001, N10665, N10675,N10629, and N10624 |

| ASTM/ASME SB409 UNS N08120, UNS N08890,UNS N08800, UNS N08810,UNS N08811 |

| ASTM/ASME SB424 UNS N08825, UNS N08221,UNS N06845 |

| ASTM/ASME SB434 UNS N10003, UNS N10242 |

| ASTM/ASME SB435 UNS N06002, UNS N06230, UNS N12160,UNS R30556 |

| ASTM/ASME SB443 UNS N06625, UNS N06219 |

| ASTM/ASME SB463 UNS N08020 |

| ASTM/ASME SB536 UNS N08330, UNS N08332 |

| ASTM/ASME SB575 UNS N10276, N06022, N06455, N06035, N06044, UNS N06058,UNS N06059,UNS N06200,UNS N10362,UNS N06210,UNS N06686 |

| ASTM/ASME SB582 UNS N06007, N06975, N06985, N06030 |

| ASTM/ASME SB625 UNS N08925, UNS N08031, UNS N08034, UNS N08932, UNS N08926, UNS N08354, UNS N08830, UNS R20033 |

| ASTM/ASME SB688 UNS N08366, UNS N08367 |

| ASTM/ASME SB709 UNS N08028 |

| Pure Nickel |

ASTM/ASME SB162 Ni200(UNS N02200), Ni201(UNS N02201) |

| Claded materials |

ASTM/ASME SB898, SB263, SB264 or closer |

| explosion cladding, making materials of 2 in 1 or 3 in 1. |

| Titanium- Steel, Nickel-Steel,Titanium- Copper, |

| Stainless Steel- Carbon Steel, Alloys- Steel etc. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!