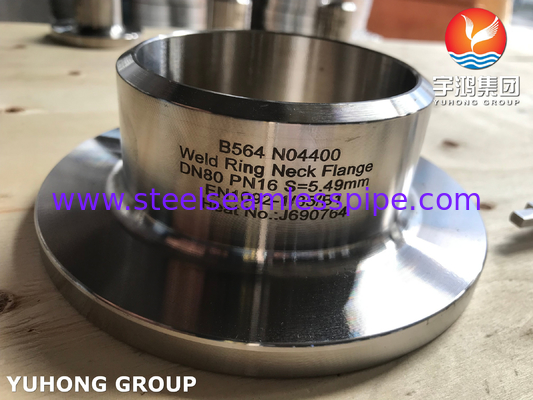

B564 N04400 Weld Neck Raised Face Nickel Copper Alloy Flange for Mining Industry

Monel 400 weld-neck flanges are a nickel-copper alloy (approx. 67% nickel - 23% copper) that is resistant to high-temperature seawater and steam, as well as salt and corrosive solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy has good corrosion resistance, weldability and high strength. It has a low corrosion rate in fast-flowing brackish or seawater, excellent resistance to stress corrosion cracking in most freshwaters, and is also resistant to a wide range of corrosive conditions, making it widely used in marine and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids after degassing. Due to the high copper content, Alloy 400 is quickly attacked by nitric acid and ammonia systems.

Chemical Composition

|

Element

|

Content (%)

|

|

Nickel, Ni

|

Remainder

|

|

Copper, Cu

|

28-34

|

|

Iron, Fe

|

2.5 max

|

|

Manganese, Mn

|

2 max

|

|

Silicon, Si

|

0.5 max

|

|

Carbon, C

|

0.3 max

|

|

Sulphur, S

|

0.024

|

|

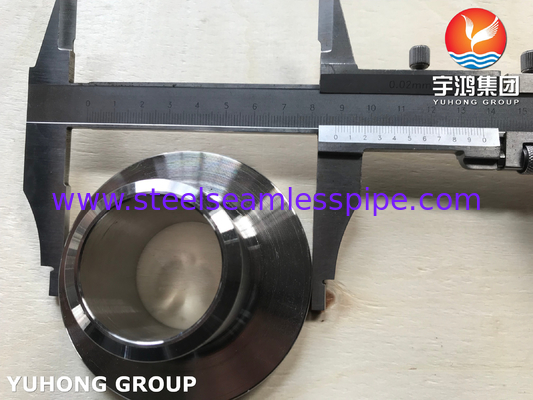

Weld Neck Flanges

Weld Neck Flanges are a very common type of pipe flanges used in various industrial applications. They have a long tapered hub and are often used for high pressure applications.

We are a fast growing organization, engaged in manufacturing, supply and export of welding neck flanges, industrial weld neck flanges and forged flanges. Our weld neck flanges are drilled with the wall thickness of flange having the same dimensions of pipe. Flanges for heavier pipes have smaller bore, while flanges of lighter pipes have larger bore. These weld neck flanges, industrial weld neck flanges, forged flanges are normally used for high-pressure, cold or hot temperature.

|

|

|

Stainless Steel WNRF Flanges: A182, GR F304, F309S, F316, F321, F347, F347H

Carbon Steel WNRF Flanges: A105

Alloy Steel WNRF Flanges : A182, GR F1, F11, F22, F5, F9, F91

Nickel Alloy WNRF Flanges : B564, GR N02200, N06022, N04400, N06625, N08811, N06600

Copper Alloy WNRF Flanges: SB151, GR C70600, C71500, C71520

WNRF Flanges Standard

ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S : BS4504 , BS4504, BS1560, BS10

Test Certificate

Manufacturer Test Certificate as per EN 10204 / 3.1B

Applications

-

Marine installations, pumps, valves and piping systems for seawater applications

-

Chemical plant equipment

-

Aerospace applications

-

Musical instruments

-

Heat exchangers

-

High Pressure Applications

-

Offshore Applications

-

Onshore applications

-

Welded pressure vessels for storage of cryogenic substances

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!