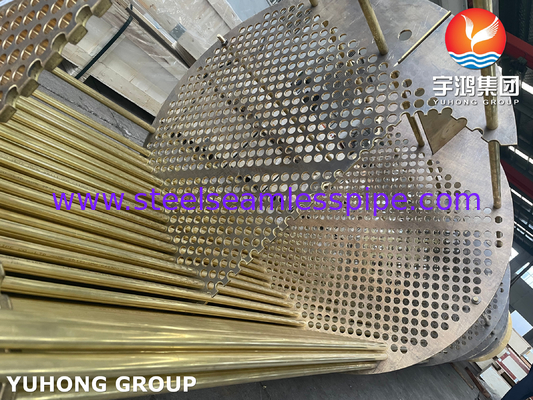

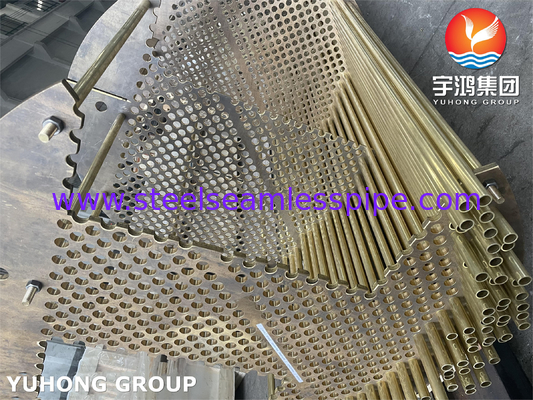

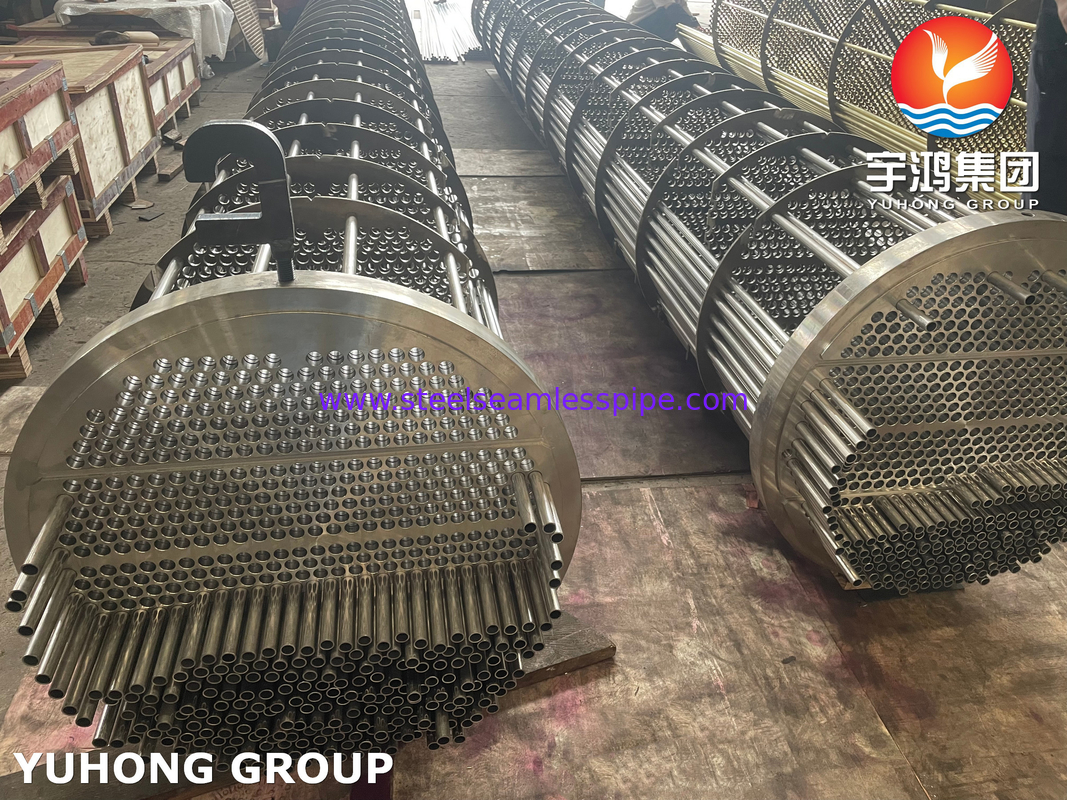

Stainless Steel / Carbon Steel / Copper Alloy Tube Bundle For Heat Exchanger

Tube Bundles are usually used for heat exchangers, like shell and tube heat exchangers, tubular heat exchangers. We, YUHONG GROUP, are professional in manifacturing stainless steel / carbon steel / copper alloy / nickel alloy tube bundles with high quality. We also supply heat exchanger components, like tubesheets, nozzles, heads, an so on. These tube bundles are also widely applied in industries like petrochemical industry, chemical industry, power plant, oil and gas plant, etc..

A tube bundle for a heat exchanger can be constructed using various materials depending on the specific requirements of the application. Here's a brief overview of the characteristics of stainless steel, carbon steel, and copper alloy for such purposes:

1.Stainless Steel:

Stainless steel is known for its excellent corrosion resistance, making it suitable for applications where the fluid being processed is corrosive.

It offers good strength and durability, making it suitable for high-pressure and high-temperature applications.

Common stainless steel grades used in heat exchanger tubing include SS304, SS316, and SS321.

2.Carbon Steel:

Carbon steel is relatively less expensive compared to stainless steel and is often used in applications where corrosion resistance is not the primary concern.

It offers good thermal conductivity, making it efficient for heat transfer.

Carbon steel is suitable for applications where the operating temperature and pressure are within its limits.

It may require protective coatings or treatments to prevent corrosion.

3.Copper Alloy: ASME SB111 UNS C70600, C44300, C68700, C71500, C71640 and so on.

There are two different of tube bundles: Straight Tubes and U Bend Tubes.

Stright Tube bundle: As both ends are in open status, the hot liquid is pumped through the bundle in a straight line from one end of the tank shell to another end of tank shell. This type is efficient, but it requires more effort to open the tank shall to remove the bundle to do cleanning or maintainace.

U Bend Tube Bundle: This bundle has entry and exit points on the same side of the shell on a tube shell cap divided into two sealed chambers. The tubes are bent in U shape, which leaves the entry chamber and travels to the opposite end of the shell and return in the opposite direction to the exit chamber. U bend tube bundle also suits well with high temperature differences, relieving most thermal expansion and reducing contraction stresses in the bundle.

What are the components of tube bundle heat exchanger?

The components of a shell and tube heat exchangers include the shell, shell cover, tubes, channel, channel cover, tube sheet, baffles, and nozzles.

Applications:

Chemical Production

Petroleum Industry

Energy Power

Pharmaceutical Industry

Oil And Gas Plant

Refineries

Power Generation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!