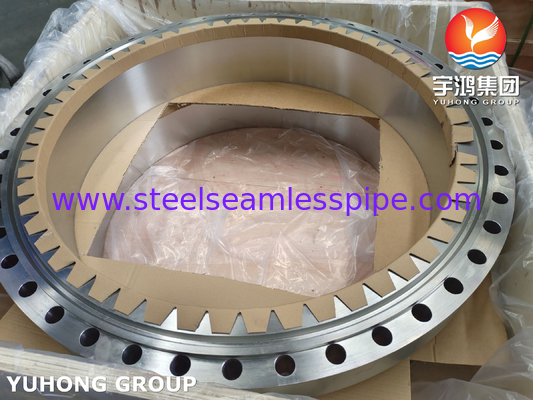

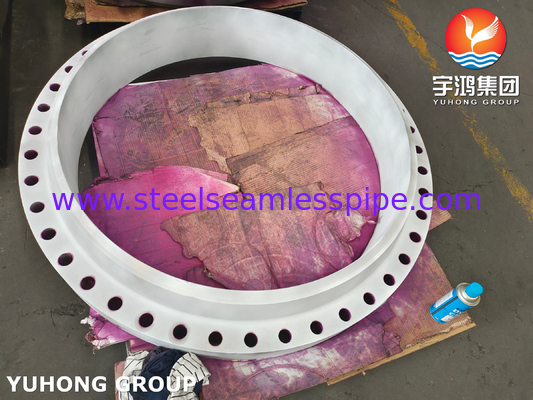

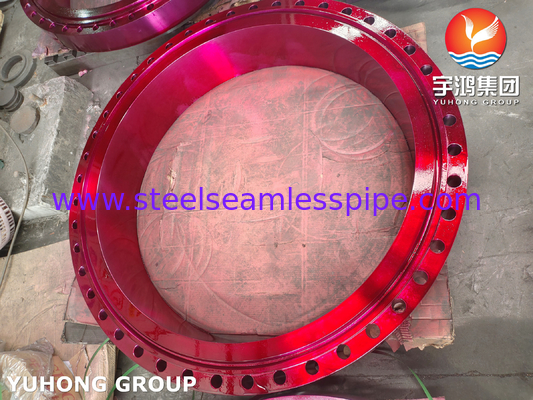

ASME B16.5 ASTM A182 F310 Stainless Steel WNRTJ Flange for Industries

ASTM A182 F310 is a specification for a high-temperature alloy steel known as stainless steel grade 310. with a high content of chromium and nickel. It also contains a small amount of manganese, silicon, phosphorus, sulfur, and carbon. This composition provides excellent resistance to oxidation, corrosion, and high-temperature scaling. The dimensions of ASTM A182 F310 WNRTJ flanges conform to standard dimensions specified by ASME B16.5 or ASME B16.47. These standards provide guidelines for flange sizes, bolt hole patterns, and facing types.

ASTM A182 F310/310S/310H Flange Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

| SS 310H | – | S31009 | – | – | – | – | –

|

ASTM A182 F310/310S/310H Flange Chemical Composition

| Grade | Ni | P | S | C | Mn | Si | Cr | Mo | Fe |

| SS 310 | 19.00 – 21.00 | 0.020 max | 0.015 max | 0.015 max | 2.0 max | 0.15 max | 24.00 – 26.00 | 0.10 max | 54.7 min |

| SS 310S | 19.00 – 21.00 | 0.045 max | 0.030 max | 0.08 max | 2.0 max | 1.00 max | 24.00 – 26.00 | 0.75 max | 53.095 min |

| SS 310H | 19.00 – 21.00 | 0.045 max | 0.030 max | 0.04 – 0.10 | 2.0 max | 1.00 max | 24.00 – 26.00 | – | 53.885 min |

ASTM A182 SS 310 Flanges Mechanical Properties

| Tensile Strength | Yield Strength (0.2%Offset) | Density | Melting Point | Elongation |

| Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 7.9 g/cm3 | 1402 °C (2555 °F) | 40 % |

Flanges Grades

Stainless Steel Flange: F304, F304L, F304H, F316, F316L, F316Ti, F310, F310S, F321, F321H, F317, F317L, F347, F347H, F904L etc

Duplex Steel Flange: UNS S31803, 2205, S31254 (254SMO)

Super Duplex Steel Flange : UNS S32750, UNS S32760, UNS S32304, S31500

Carbon Steel Flange: ASTM A105, A105N etc.

Alloy Steel Flange: F1, F11, F22, F5, F9, F91 etc.

Nickel Alloy Flange as below

Monel 400 & K500,

Inconel 600, 601, 617, 625, 690, 718, X-750.

Incolloy 800, 800H, 800HT, 825, 925.

Hastelloy C22, C4, C276, S, C2000, G-30, G-35, X, N, B, B-2, B-3.

Copper Alloys Flanges: Copper, Brass & Gunmetal

Various Kinds of Flanges we can supply as below

1. Slip-on Flanges.

Slip-on Flanges have a lower initial cost than welding neck flanges because they require less accuracy in cutting pipe to length, and they provide a greater ease of alignment in assembly. However, their calculated strength under internal pressure is approximately 2/3's the strength of welding neck flanges, and their life under fatigue is 1/3 shorter. Slip-on Flanges are limited to 1/2" to 2½" sizes in 1500lbs standard.

2. Threaded Flanges

Threaded Flanges are used for special applications. They can be assembled without welding and can be used in extremely high pressure services--at or near atmospheric pressure--where alloy steel is essential for strength. Threaded flanges are not suited for conditions involving temperature or bending stresses, or under cyclic conditions where leakage through the threads may occur.

3. Weld Neck Flanges

Weld Neck Flanges have a long tapered hub and gradual transition of thickness in the region of the butt weld joining them to the pipe. The tapered hub provides important reinforcement to the flange and resistance to dishing. This type of flange is preferred for severe service conditions resulting from high pressure, sub-zero or high temperatures.

4. Blind Flanges

Blind Flanges are used to blank off the ends of piping, valves and pressure vessel openings. Blind Flanges can handle high stress from internal pressure and bolt loading since the maximum stresses in the blind flange are bending stresses at the center.

5. Socket Weld Flanges

Socket Weld Flanges were developed for use on small size high pressure piping. With an internal weld, socket weld flanges are stronger and have greater fatigue strength than double welding a slip-on flange. Smooth bore conditions can be easily attained by grinding the internal weld. This flange is commonly used in chemical process piping.

6. Lap Joint Flanges

Lap Joint Flanges are used with lap joint stubs. Lap joint flanges are commonly used in carbon or low alloy steel piping systems that need to be frequently dismantled for inspection and cleaning. They should not be used at any points where severe bending stresses occur.

Applications

ASTM A182 F310 WNRTJ flanges are commonly used in industries such as petrochemical, chemical, power generation, and oil and gas.

They are suitable for applications involving high temperatures, such as heat exchangers, boilers, process piping, and thermal processing equipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!