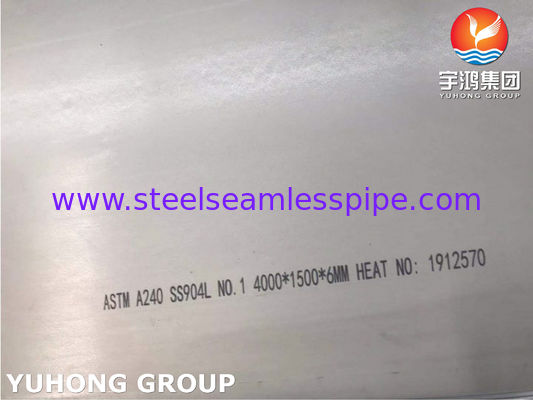

ASTM A240 904L NO8904 Stainless Steel Plate Sheet Coil

ASTM A240 is a specification for stainless steel plate, sheet, and strip for pressure vessels and for general applications. It covers grades such as 304, 304L, 316, 316L, 321, 347, and 904L.

Stainless steel 904L is a low carbon, high alloy austenitic stainless steel with excellent corrosion resistance. It is commonly used in chemical processing, oil and gas production, and other demanding environments where corrosion resistance is critical.

ASTM A240 stainless steel 904L plate is available in various thicknesses, widths, and lengths. It is typically supplied in the annealed condition and can be further heat treated to enhance its properties.

The mechanical properties of ASTM A240 stainless steel 904L plate include a tensile strength of 490 MPa (71 ksi), a yield strength of 220 MPa (32 ksi), and an elongation of 35%.

The execution standard for 904L seamless steel pipe is ASTM A240/ASME

904L belongs to austenitic stainless steel, with physical and mechanical properties: density: 8.24g/cm3. Tensile strength: σ B ≥ 520Mpa. Elongation: δ≥ 35%.It has good resistance to spot corrosion and Crevice corrosion, high resistance to stress corrosion cracking, good resistance to intergranular corrosion, good workability and weldability.

904L is a low-carbon austenitic stainless steel that can be used under severe corrosion conditions. It contains 25% nickel and 4.5% molybdenum, and has good resistance to chloride stress corrosion cracking. Compared with 316L and 317L, 904L has excellent corrosion resistance. Due to the addition of Cu, the alloy exhibits excellent corrosion resistance to reducing acids such as sulfuric acid and phosphoric acid.

Common applications include the production and transportation of sulfuric acid, metal pickling in sulfuric acid, papermaking and related industries, and the chemical and pharmaceutical industries.

ASTM A240 SS904L Stainless Steel Plate Chemical Composition

| Element |

SS 904L |

| C |

0.020 max |

| Mn |

2 max |

| Si |

1 max |

| P |

0.040 max |

| S |

0.030 max |

| Cr |

19 – 23 |

| Ni |

23 – 28 |

| Mo |

4 – 5 |

| Cu |

1 – 2 |

ASTM A240 SS904L Stainless Steel Plate Mechanical Properties

| Element |

SS 904L |

| Density |

7.95 g/cm3 |

| Melting Point |

1350 °C (2460 °F) |

| Tensile Strength |

Psi – 71000 , MPa – 490 |

| Yield Strength (0.2%Offset) |

Psi – 32000 , MPa – 220 |

| Elongation |

35% |

Material Testing

1. Chemical processing

2. Oil and gas industry

3. Desalination plants

4. Food processing industry

5. Marine industry

6. Heat exchangers

7. Petrochemical industry

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!