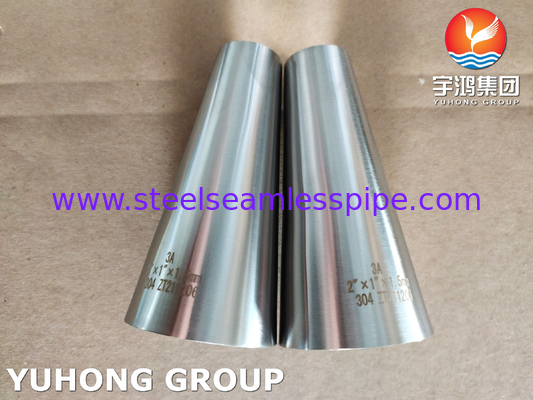

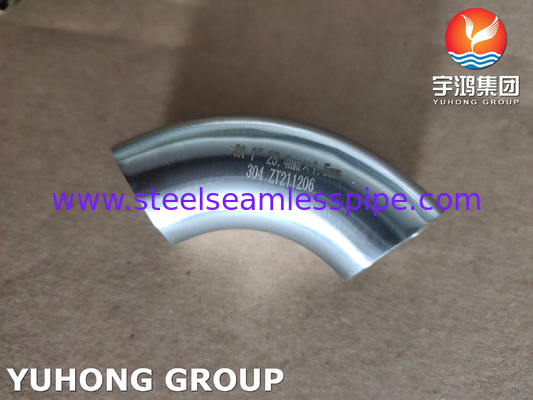

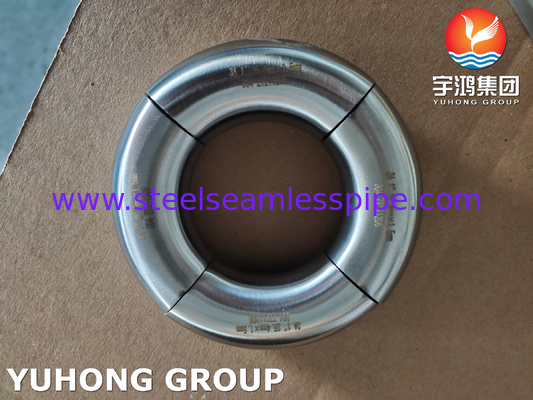

Sanitary pipe fittings

Sanitary pipe fittings are components used in the installation of plumbing systems that carry fluids or gases. These fittings are designed to ensure that the fluid or gas being transported is not contaminated by the surrounding environment. Sanitary pipe fittings are commonly used in the food and beverage, pharmaceutical, and biotech industries, as well as in clean rooms and other controlled environments. Examples of sanitary pipe fittings include clamps, elbows, tees, reducers, and valves. These fittings are typically made from materials such as stainless steel, brass, or plastic, and are designed to be easy to clean and maintain.

Sanitary Fitting Types

A sanitary fitting can be attached to your system in a number of ways. It could fasten with a single bolt, having double pin hinges on the other side, or you could choose a design that fastens with bolts on each side and no hinge. If you’re dealing with certain high–pressure ASME applications, then you might include a third bolt in a hinged design, on the side of the hinge itself.

While some manufacturers may offer sanitary fittings with a single pin hinge, at LJ Star we firmly believe that you need to have at least two pins. This ensures that you have a sturdier and even clamping force.

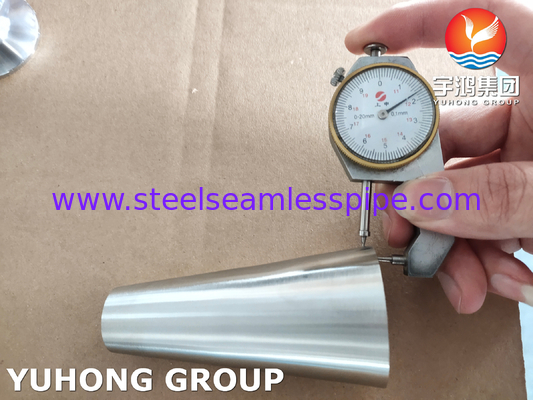

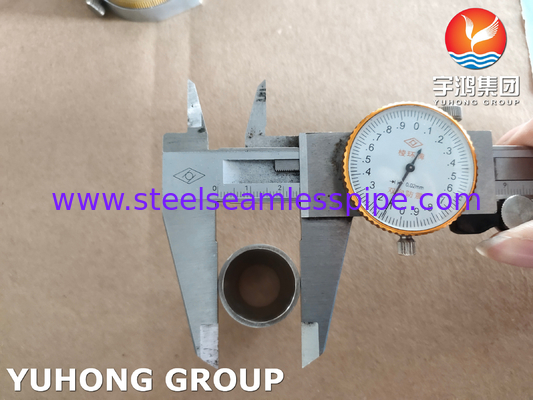

Sanitary Pipe Fitting Sizing

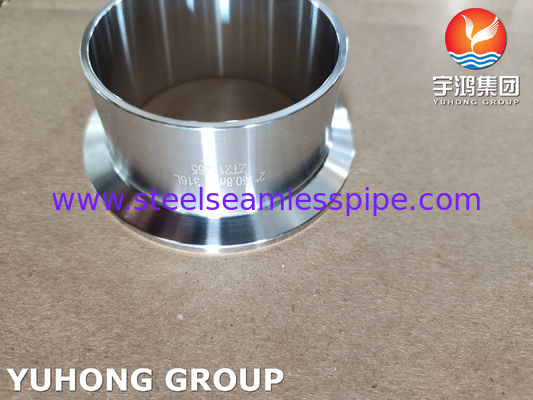

Simply put, the size of your sanitary fitting is based on the sizes of the ferrules that it is connecting. This has to do with the physical mechanics behind how these parts are mated. Take a look at one of your ferrules. You’ll notice that it’s the beveled surface on the outside diameter of the ferrule that’s connected with the inside diameter of your sanitary fitting. This is the same for the other ferrule as well. When you tighten the clamp, you pull both ferrules together and create a sanitary seal.

Choose too big of a clamp, even just by a fraction of an inch, and you won’t have the sanitary connection you need. That’s because the clamp will be too loose around the ferrules or have openings that bacteria could find their way through. If your clamp is too small, you could warp the ferrules and damage your system.

While clamps should be sized specifically to your ferrules, typical sanitary fittings range from ½” to 12” for the tubing and 4” to 12” for the piping. For LJ Star’s clamps, sizes and dimensions are standardized by ASME BPE to ensure product consistency and reliability. With this standardization, the flange’s outside diameter is the same for 1/2” and 3/4” fittings, as well as for 1” and 1-1/2” fittings. Make sure that you measure the outside diameter of the tubing itself, not the flange, when choosing the size of your gaskets.

Material Selection

Stainless steel is the go-to material for sanitary fittings, and for a good reason. It offers an unrivaled mechanical strength and abrasion resistance, making it a great option for even the most challenging applications.

The main choice here is whether to go with 304 or 316 stainless steel. 304 stainless is cheaper and easier to get, but 316 stainless has superior corrosion resistance. Make sure to choose 316 stainless steel if your application involves any of the following:

Advantages

1. Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it ideal for use in sanitary applications where hygiene is of utmost importance. It can withstand exposure to harsh chemicals, acids, and alkaline solutions without corroding or deteriorating.

2. Durability: Stainless steel is a durable material that can withstand high pressure, high temperature, and extreme weather conditions. It is resistant to wear and tear, making it ideal for use in high-traffic areas.

3. Aesthetic Appeal: Stainless steel has a sleek and modern appearance that adds to the aesthetic appeal of any facility. It is easy to clean and maintain, ensuring that it always looks its best.

4. Easy to Fabricate: Stainless steel is easy to fabricate, making it easy to create custom fittings for specific applications. It can be welded, brazed, or soldered to create a seamless connection.

5. Hygienic: Stainless steel is a non-porous material that is easy to clean and sanitize. It does not harbor bacteria, making it ideal for use in food processing, pharmaceuticals, and other sanitary applications.

6. Cost-Effective: Although stainless steel may be more expensive than other materials, it is a cost-effective investment in the long run. It requires minimal maintenance and has a long lifespan, reducing the need for frequent replacements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!