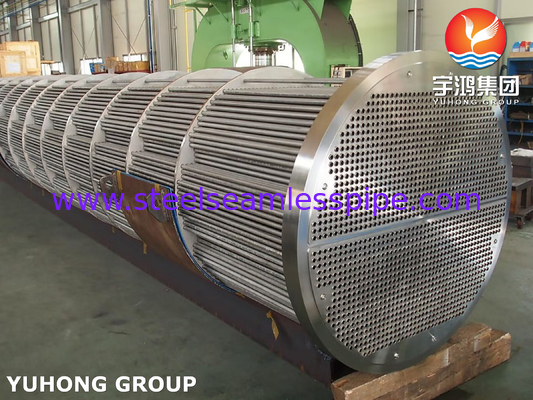

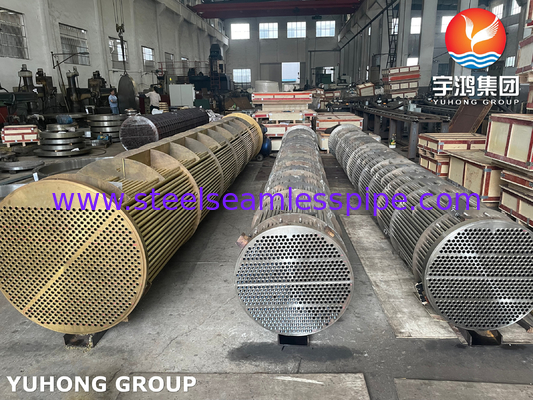

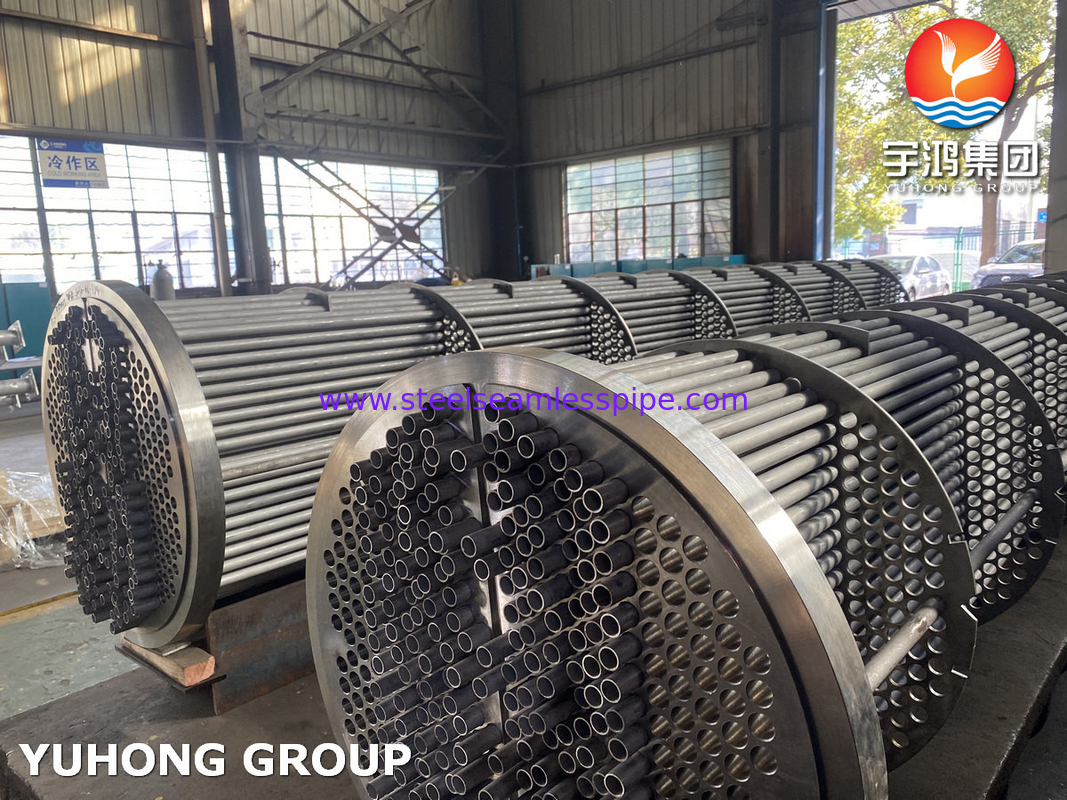

Heat Exchanger Tube Bundle, Stainless Steel Seamless Tube ASME SA213 TP316L , Tubesheet ASME SA182 F316L

Yuhong Group already export more than 85 countries and give service for more than 3000 clients also. During last 10 years we finished more than 50 sets of oil furnace/ Fir Furnace/Steam Reforming Furnace... Yuhong Group already start to support client of heat exchanger parts also , which like : Stationary Tubesheet, Floating Tubesheet, Baffle, Nozzle, Dishead, testing ring, back ring , Back flange, support plate, Tie rod, steel tube , fin tube, u bend tube , and material contain : Stainless Stee, Duplex Steel , Super Duplex Steel , Nickel Base Alloy Steel , Cr- Mo Alloy Steel , Carbon Steel , Copper / Copper Alloy Steel , Titanium , ...

| YUHONG GROUP Heat Exhanger Tube bundle parts- 081-E-0001 A/B/C |

| NO. |

POS |

DESPRITION |

SIZE |

MATERIAL |

OVERLAY CLADDING |

QUANTITY |

| A |

A--0 |

Seamless TUBE |

Ø19.05×2.11(min) x7315mm |

ASME SA213 TP316L |

/ |

2490 |

PCS |

| 11 |

3-1 |

S.T. TUBE SHEET |

Ø997×81mmT |

SA350 LF2 CL1N |

8MM SS316L |

3 |

PC |

| 12 |

3-2 |

F.L. TUBE SHEET |

Ø926×81mmT |

SA350 LF2 CL1N |

8MM SS316L |

3 |

PC |

| 17 |

4-5 |

GASKET |

Ø926×4mmT |

SS316L+GRAPHITE |

/ |

9 |

PCS |

| 21 |

5-4 |

STUD B./2H.N |

1-8UNC×395L |

SA320-L7/SA194-2H |

/ |

108 |

PCS |

| 22 |

5-5 |

SQ. STUD B./2H.N |

1-8UNC×445L |

SA320-L7/SA194-2H |

/ |

33 |

PCS |

| 27 |

7-1 |

F.T H.D FLANGE |

Ø1026×Ø894×100mmT |

SA350 LF2 CL1N |

3MM SS316L |

3 |

PC |

| 28 |

7-2 |

F.T H.D COVER |

Ø894×25mmT |

SA516 GR.70N |

3MM SS316L |

3 |

PC |

| 29 |

7-3 |

BACKING RING |

Ø1026×Ø894×167mmT |

SA350 LF2 CL1N |

/ |

3 |

PC |

| 32 |

10 |

CONNECTION PIECES |

Ø1018×Ø914×27mT |

SA516 GR.70N |

/ |

6 |

PCS |

| 33 |

1-1 |

BAFFLE |

Ø935.2×649.2×10mmT |

SA516 GR.70N |

/ |

3 |

PC |

| 34 |

1-2 |

BAFFLE |

Ø935.2×649.2×8mmT |

SA516 GR.70N |

/ |

21 |

PCS |

| 35 |

1-3 |

BAFFLE |

Ø935.2×649.2×10mmT |

SA516 GR.70N |

/ |

3 |

PC |

| 36 |

1-4 |

BAFFLE |

Ø935.2×649.2×8mmT |

SA516 GR.70N |

/ |

21 |

PCS |

| 37 |

1-5 |

SUPPORT PLATE |

Ø935.2×16mmT |

SA516 GR.70N |

/ |

3 |

PC |

| 38 |

3 |

TIE ROD / NUTS |

Ø13×6869mmL |

SA36/194-2H |

/ |

24 |

PCS |

| 39 |

4-1 |

SEALING STRIP |

8×27×5579mmL |

SA516 GR.70N |

/ |

12 |

PCS |

| 40 |

4-2 |

SEALING STRIP |

8×56.5×5579mmL |

SA516 GR.70N |

/ |

6 |

PCS |

| 41 |

5 |

SLIDING SHOE |

16×41×6843mmL |

SA516 GR.70N |

/ |

6 |

PCS |

| 42 |

6 |

IMPINGEMENT PLATE |

T=12mm |

SA516 GR.70N |

/ |

3 |

PC |

| 43 |

7-1 |

LIFTING LUG |

16×80×190 |

SA516 GR.70N |

/ |

6 |

PCS |

| 44 |

7-2 |

LIFTING LUG |

16×80×190 |

SA516 GR.70N |

/ |

6 |

PCS |

| 45 |

7-3 |

LIFTING LUG |

16×80×140 |

SA516 GR.70N |

/ |

9 |

PCS |

| 46 |

7-4 |

LIFTING LUG |

16×95×170 |

SA516 GR.70N |

/ |

12 |

PCS |

| 47 |

7-5 |

LIFTING LUG |

25×110×160 |

SA516 GR.70N |

/ |

12 |

PCS |

| 48 |

7-6 |

LIFTING LUG |

T=25mm |

SA516 GR.70 |

/ |

12 |

PCS |

| 49 |

7-7 |

RIB PLATE |

T=25mm |

SA516 GR.70 |

/ |

12 |

PCS |

| 50 |

7-8 |

REINFORANCE PAD |

T=14mm |

SA516 GR.70 |

/ |

12 |

PCS |

| 51 |

9-1 |

EYE BOLT |

M36×P4 |

SA36 |

/ |

12 |

PCS |

| 52 |

9-2 |

PLUG |

M36×P4×75 |

SS304 |

/ |

12 |

PCS |

| 53 |

10 |

CENTERING PIN LUG |

T=25mm |

SA516 GR.70 |

/ |

6 |

PCS |

| A |

HEAT TREATMENT |

| B |

HYDROSTATIC TEST |

| A |

HARDNESS TEST |

| B |

MECHANICAL PROPERTY |

| A |

CHEMICAL ANALYSIS REPORT |

| B |

WELDING PROCEDURE SPECIFICATIONS |

Application:

HVAC Systems: Heat exchangers are integral components in heating, ventilation, and air conditioning systems. They transfer heat between the air and a fluid (such as water or refrigerant) to either heat or cool indoor spaces.

Industrial Processes: Many industrial processes require precise temperature control. Heat exchangers are used to regulate temperatures in chemical processing, oil refining, power generation, food processing, and pharmaceutical production.

Refrigeration and Cooling: Heat exchangers play a critical role in refrigeration cycles, where they transfer heat from the refrigerant to the outside environment, thereby cooling the interior space.

Renewable Energy: Heat exchangers are used in renewable energy systems like solar thermal collectors and geothermal power plants to transfer heat from renewable sources to usable mediums such as water or air.

Automotive: In vehicles, heat exchangers are used in cooling systems to regulate engine temperature by transferring heat from coolant to air via radiators.

Waste Heat Recovery: Heat exchangers can capture and reuse waste heat from industrial processes or exhaust gases, improving energy efficiency and reducing operational costs.

Domestic Appliances: They are present in household appliances like refrigerators, air conditioners, and water heaters, where they facilitate heat transfer to maintain desired temperatures.

Heat Pumps: These devices use heat exchangers to transfer heat between indoor and outdoor environments for heating or cooling purposes in residential and commercial buildings.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!