Low Finned Tube Stainless Steel Extruded Fin Tube For Heat Exchanger

Overview

ASTM B111 is an American Society of Testing and Materials (ASTM) standard that specifies requirements for seamless copper-nickel (CuNi) low finned tubes used in heat exchangers and other similar applications. The designation C70600-O61 refers to specific grades and finishes of the material.

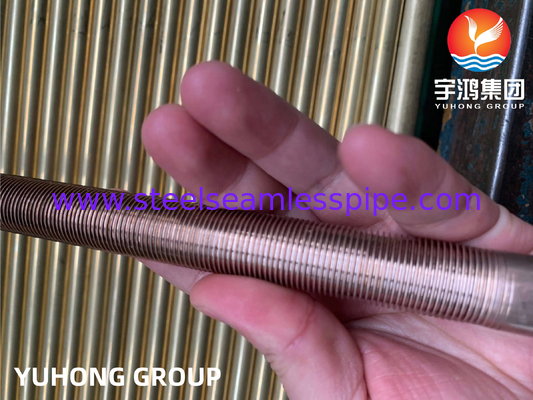

C70600 refers to the alloy composition, which is a copper-nickel alloy with a chemical composition of approximately 70% copper and 30% nickel. This alloy offers excellent corrosion resistance, particularly in chloride environments, making it suitable for use in marine, chemical processing, and industrial applications where harsh conditions are prevalent.

O61 refers to the finish or surface treatment applied to the tube. In this case, O61 indicates that the tube has undergone an oxygen-free brazing process (OFB), where the seam between the copper and nickel is brazed without the addition of any oxygen, resulting in a strong and durable joint with minimal metal loss.

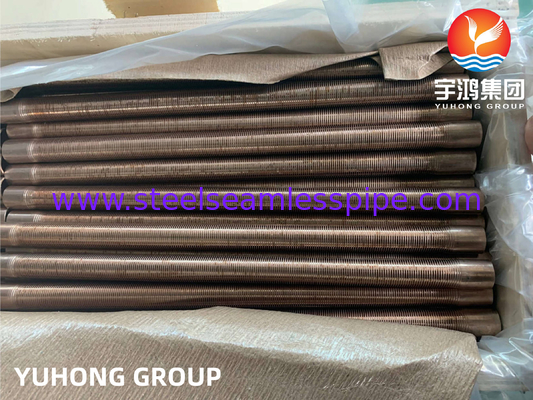

In summary, ASTM B111 C70600-O61 Copper Nickel Low Finned Tube is a high-quality, corrosion-resistant tube with a seamless construction and an OFB brazed seam, ideal for use in demanding heat exchange applications where the material's longevity and resistance to environmental factors are crucial.

What's Fin Tube ?

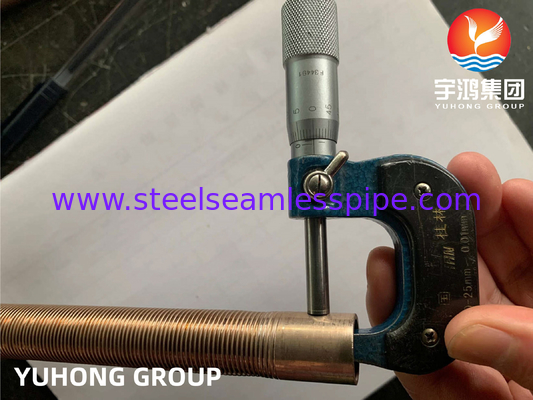

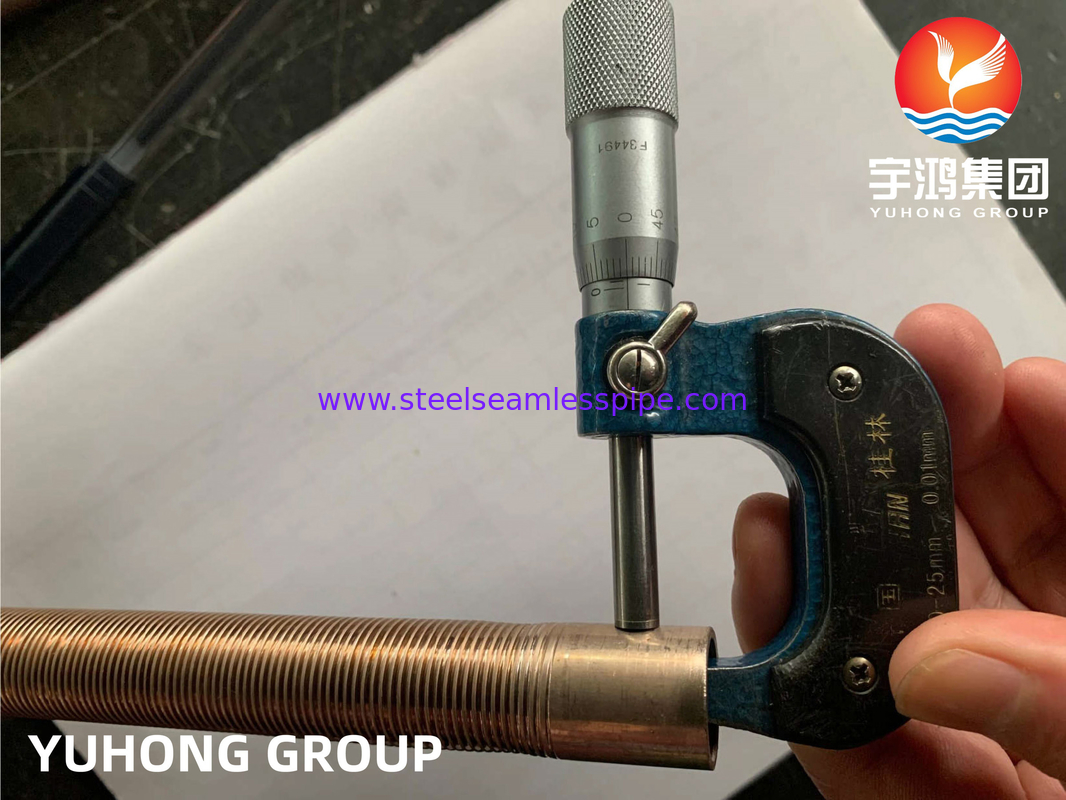

Low-fin (integral) tube is an extruded tube composed of short and low fins, and a high-efficiency heat-exchange tube type in which threaded fins are formed on the outer surface of the heat-exchange tube by rolling. The tube and fin are in the same piece of tube, also known as "N" fin type.

Because Low Finned Tube is an integral tube, there is only one material for the tube and fins

We offer you a wide range of materials and can expand our offering at any time to meet your specific needs in terms of thermal conductivity, mechanical properties or corrosion resistance.

Low fin tube advantages

Low fin tube, also known as low-fin tubes or microchannel heat exchangers, have several advantages over conventional finned tubes in various applications, particularly in high heat transfer and compact designs:

1. Enhanced Heat Transfer: Low fin tubes have thinner and closely spaced fins, which increase the surface area per unit volume. This results in higher heat transfer rates due to the greater contact between the fluid and the metal walls, allowing for more efficient cooling or heating.

2. Compact Size: The reduced fin size allows for a smaller overall footprint compared to traditional finned tubes. This makes them ideal for space-constrained applications like electronics, appliances, and aerospace where weight and volume are critical factors.

3. Improved Pressure Drop: With fewer and thinner fins, the pressure drop across the heat exchanger is lower. This can be beneficial in systems where maintaining a consistent flow rate is important, or where headroom for pressure loss is limited.

4. Reduced Manufacturing Cost: The simpler manufacturing process for low fin tubes can lead to lower material and labor costs, making them more cost-effective compared to high-fin designs.

5. Lower Maintenance: Due to their smaller size and improved heat transfer, low fin tubes may require less frequent cleaning or maintenance since they can handle fouling more effectively than conventional tubes.

6. Reduced Noise: Smaller fins typically generate less turbulence, resulting in quieter operation, which can be advantageous in noise-sensitive environments.

7. Easier Integration: Low fin tubes can be more easily incorporated into existing designs without requiring extensive redesigns or modifications.

8. Enhanced Thermal Cycling Performance: The smaller surface area of the fins reduces stress on the material during thermal cycling, potentially increasing the lifespan of the heat exchanger.

9. Higher Efficiency: In some cases, low fin tubes can achieve higher overall efficiency due to the higher heat transfer coefficients and reduced pressure drop.

However, it's essential to consider the specific application requirements, as low fin tubes might not always be the best choice. For instance, they may not perform as well in situations where large temperature differences or high flow velocities are present.

The performance degradation of a heat exchanger is essentially due to two phenomenons which occurs over time :

- Increased fouling resistance due to impurity accumulation contained in both fluids.

- Increased thermal resistance at the tube-to-fin bond due to thermal cycling dilatation of the materials and to corrosion at the fin base or root. These factors creates a loss of contact or bond pressure in between the fins and the tube.

| Type |

Description |

Base tube |

Fin specification (mm) |

| O.D. (mm) |

Fin pitch |

Fin height |

Fin thick |

| Embedded |

G-type fin tueb |

16-63 |

2.1-5 |

<17 |

~0.4 |

| Extruded |

Single metal combined metal |

8-51 |

1.6-10 |

<17 |

0.2-0.4 |

| Low fin tube t-type fin tube |

10-38 |

0.6-2 |

<1.6 |

~0.3 |

| Bamboo tube corrugated tube |

16-51 |

8-30 |

<2.5 |

/ |

| Wound |

l/kl/ll type fin tube |

16-63 |

2.1-5 |

<17 |

~0.4 |

| String |

String fin tube |

25-38 |

2.1-3.5 |

<20 |

0.2-0.5 |

| U-type |

U-type tube |

16-38 |

/ |

/ |

/ |

| Welding |

HF-welding fin tube |

16-219 |

3-25 |

5-30 |

0.8-3 |

| H/HH type fin tube |

25-63 |

8-30 |

<200 |

1.5-3.5 |

| Studed fin tube |

25-219 |

8-30 |

5-35 |

φ5-20 |

The common application fields are:

- heat exchangers for power plants (electric, nuclear, thermal and geothermal power plants)

- high corrosive systems (condensers, evaporators, sea water desalinations, fertilizing, urea systems, ammonia, gas, corrosive acids)

- chemical and petrochemical industries

- food processing and refrigeration industries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!