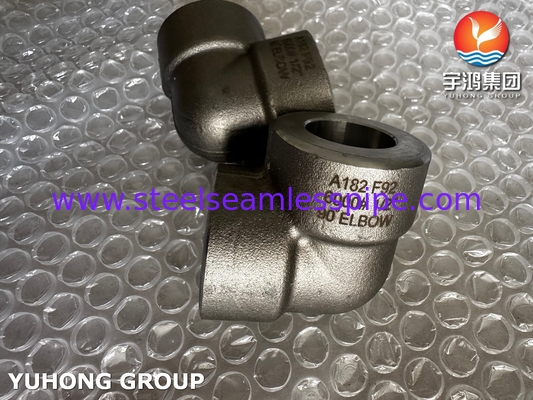

ASTM A182 F92 90 deg Stainless Steel Elbow For Chemical Processing B16.11

ASTM A182 Elbows are used in a wide range of industries, including chemical processing, food handling, and marine applications.

Standard A182 covers forged or rolled alloy steel, carbon steel, and stainless steel fittings.

The dimensions of an elbow typically include the nominal pipe size (NPS), wall thickness, and sometimes the length of the straight portion of the elbow. These dimensions ensure compatibility with existing piping in the system.

These elbows can be manufactured using a variety of methods including forging, rolling, or bending. The choice of method depends on the specific requirements of the application and the material properties.

Chemical Composition Requirements

| Chemical Composition of ASTM A182 Low Alloy Steels, % |

| ID. Symbol* |

C |

Mn |

P |

S |

Si |

Cr |

Mo |

Others |

| F1 |

0.28 |

0.60-0.90 |

0.045 |

0.045 |

0.15-0.35 |

- |

0.44-0.65 |

- |

| F2 |

0.05-0.21 |

0.60-0.80 |

0.040 |

0.040 |

0.10-0.60 |

0.50-0.81 |

0.44-0.65 |

- |

| F5 |

0.15 |

0.30-0.60 |

0.030 |

0.030 |

0.50 |

4.0-6.0 |

0.44-0.65 |

*A |

| F5A |

0.25 |

0.60 |

0.040 |

0.030 |

0.50 |

4.0-6.0 |

0.44-0.65 |

*B |

| F9 |

0.15 |

0.30-0.60 |

0.030 |

0.030 |

0.50-1.00 |

8.0-10.0 |

0.90-1.10 |

- |

| F10 |

0.10-0.12 |

0.50-0.80 |

0.040 |

0.030 |

1.00-1.40 |

7.0-9.0 |

- |

*C |

| F91 |

0.08-0.12 |

0.30-0.60 |

0.020 |

0.010 |

0.20-0.50 |

8.0-9.5 |

0.85-1.05 |

*D |

| F92 |

0.07-0.13 |

0.30-0.60 |

0.020 |

0.010 |

0.50 |

8.5-9.5 |

0.30-0.60 |

*E |

| F122 |

0.07-0.14 |

0.70 |

0.020 |

0.010 |

0.50 |

10.00-11.50 |

0.25-0.60 |

*F |

| F911 |

0.09-0.13 |

0.30-0.60 |

0.020 |

0.010 |

0.10-0.50 |

8.5-9.5 |

0.90-1.10 |

*G |

| F11 CLASS1 |

0.05-0.15 |

0.30-0.60 |

0.030 |

0.030 |

0.50-1.00 |

1.00-1.50 |

0.44-0.65 |

- |

| F11 CLASS2 |

0.10-0.20 |

0.30-0.80 |

0.040 |

0.040 |

0.50-1.00 |

1.00-1.50 |

0.44-0.65 |

- |

| F11 CLASS3 |

0.10-0.20 |

0.30-0.80 |

0.040 |

0.040 |

0.50-1.00 |

1.00-1.50 |

0.44-0.65 |

- |

| F12 CLASS1 |

0.05-0.15 |

0.30-0.60 |

0.045 |

0.045 |

0.50 |

0.80-1.25 |

0.44-0.65 |

- |

| F12 CLASS2 |

0.10-0.20 |

0.30-0.80 |

0.040 |

0.040 |

0.10-0.60 |

0.80-1.25 |

0.44-0.65 |

- |

| F21 |

0.05-0.15 |

0.30-0.60 |

0.040 |

0.040 |

0.50 |

2.7-3.3 |

0.80-1.06 |

- |

| F3V |

0.05-0.10 |

0.30-0.60 |

0.020 |

0.020 |

0.10 |

2.8-3.2 |

0.90-1.10 |

*H |

| F3VCb |

0.10-0.15 |

0.30-0.60 |

0.020 |

0.010 |

0.10 |

2.7-3.3 |

0.90-1.10 |

*I |

| F22 CLASS1 |

0.05-0.15 |

0.30-0.60 |

0.040 |

0.040 |

0.50 |

2.00-2.50 |

0.87-1.13 |

- |

| F22 CLASS3 |

0.05-0.15 |

0.30-0.60 |

0.040 |

0.040 |

0.50 |

2.00-2.50 |

0.87-1.13 |

- |

| F22V |

0.11-0.15 |

0.30-0.60 |

0.015 |

0.010 |

0.10 |

2.00-2.50 |

0.90-1.10 |

*J |

| F23 |

0.04-0.10 |

0.10-0.60 |

0.030 |

0.010 |

0.50 |

1.90-2.60 |

0.05-0.30 |

*K |

| F24 |

0.05-0.10 |

0.30-0.70 |

0.020 |

0.010 |

0.15-0.45 |

2.20-2.60 |

0.90-1.10 |

*L |

| FR |

0.20 |

0.40-1.06 |

0.045 |

0.050 |

- |

- |

- |

*M |

| F36 |

0.10-0.17 |

0.80-1.20 |

0.030 |

0.025 |

0.25-0.50 |

0.30 |

0.25-0.50 |

*N

|

Alloy Steel Butt Weld Fittings

Low alloy steel fittings are engineered components made from steel that contains a small percentage of alloying elements other than carbon. These alloying elements, which can include chromium, nickel, molybdenum, vanadium, and others, enhance the steel's mechanical properties such as strength, toughness, and resistance to wear and corrosion.

Low alloy steel fittings are engineered components made from steel that contains a small percentage of alloying elements other than carbon. These alloying elements, which can include chromium, nickel, molybdenum, vanadium, and others, enhance the steel's mechanical properties such as strength, toughness, and resistance to wear and corrosion.

Low alloy steel F92

Low alloy steel F92 is a type of high strength low alloy (HSLA) steel. It is typically used in applications where high strength and toughness are required, such as in the construction of pressure vessels, boilers, and pipelines.

F92 is known for its excellent mechanical properties at both room temperature and low temperatures. Its chemical composition includes carbon (0.15-0.2%), manganese (1.3-1.6%), silicon (0.1-0.4%), phosphorus (≤ 0.04%), sulfur (≤ 0.04%), chromium (0.8-1.1%), molybdenum (0.3-0.6%), nickel (≤ 0.3%), and copper (≤ 0.3%).

This steel is also notable for its good resistance to atmospheric corrosion and it can be easily welded. It's used in industries like power generation, oil and gas, and petrochemicals.

Excellent corrosion resistance in a wide range of environments, including oxidizing acids. High strength and creep resistance at elevated temperatures. Good formability and weldability. Suitable for temperatures from cryogenic to approximately 700°C. Used in aerospace components, chemical processing equipment, and other high temperature applications where corrosion resistance and mechanical strength are critical.

This material is frequently used in demanding industrial applications due to its excellent mechanical properties and corrosion resistance, especially at elevated temperatures.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!