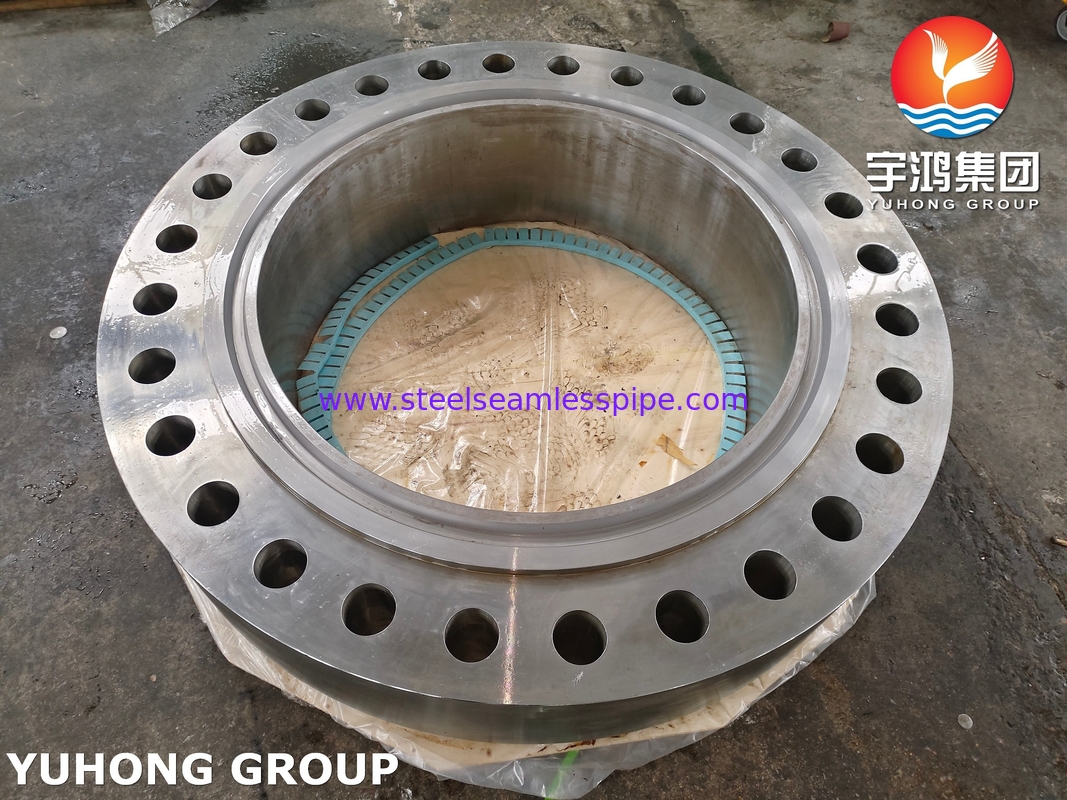

ASTM A266 / ASME SA266 Gr.2N Forged Carbon Steel Body Flange for Pressure Vessel

A forged body flange is a critical component used in piping systems, pressure vessels, or machinery to connect sections of equipment (e.g., pipes, valves, pumps) while ensuring a secure, leak-proof seal. The term "body flange" often refers to the main structural flange that forms part of a larger assembly, such as the casing of a pump, compressor, or pressure vessel.

Forging Process: Made by shaping metal (e.g., carbon steel, stainless steel, alloy steel) under extreme pressure and heat, forging aligns the metal’s grain structure, enhancing strength and resistance to stress, corrosion, and temperature fluctuations.

Key Features: High durability, uniformity, and suitability for high-pressure/temperature environments compared to cast or plate-cut flanges.

Forged body flanges act as connection points in high-pressure or high-temperature systems. They are designed to:

-

Join sections of pipes, valves, or machinery.

-

Allow easy disassembly for maintenance or repairs.

-

Withstand extreme mechanical stress, corrosion, and thermal cycling.

Material Grades of Tubesheet

| Type of materials |

Technical requirements according to |

| Duplex Stainless Steel |

ASTM/ASME SA182 F44, F45, F51, F53, F55, F60, F61 |

| Stainless Steel |

ASTM/ASME SA182 F304,304L,F316,316L, F310, F317L, F321, F347 |

| Carbon Steel |

ASTM/ASME A105, A350 LF1, LF2, A266, A694, A765 Gr.2 |

| Alloy Steel |

ASTM/ASME SA182 F1, F5, F9, F11, F12, F22, F51, A350-LF3 |

| Titanium |

ASTM/ASME SB381, Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel |

ASTM/ASME SB151, UNS 70600(Cu-Ni 90/10), 71500(Cu-Ni 70/30) |

| Brass, Al-brass |

ASTM/ASME SB152 UNS C10100, C10200,C10300,C10800,C12200 |

| Nickel Alloys |

ASTM/ASME SB169,SB171, SB564, UNS 2200, UNS 4400, UNS 8825

UNS 6600, UNS 6601, UNS 6625 |

| Alloy 20 |

ASTM/ASME SB472 UNS 8020 |

| Hastelloy |

ASTM/ASME SB564, UNS10276 ( C 276 ) |

| Claded materials |

ASTM/ASME SB898, SB263, SB264 or closer

explosion cladding, making materials of 2 in 1 or 3 in 1. |

Titanium- Steel, Nickel-Steel,Titanium- Copper,

Stainless Steel- Carbon Steel, Alloys- Steel etc. |

Chemical Composition Requirements

| Item |

Chemical Req. for ASTM A266, % |

| Gr. 1 & 2 |

Gr. 3 |

Gr. 4 |

| C |

≤ 0.30 |

≤ 0.35 |

≤ 0.30 |

| Mn |

0.40~1.05 |

0.80~1.35 |

0.80~1.35 |

| P |

≤ 0.025 |

≤ 0.025 |

≤ 0.025 |

| S |

≤ 0.025 |

≤ 0.025 |

≤ 0.025 |

| Si |

0.15~0.35 |

0.15~0.35 |

0.15~0.35 |

Heat Treatment

After forging and before reheating for heat treatment, the forgings in accordance with ASTM A266 shall be cooled in such a manner as to prevent injury and to accomplish transformation. All the ASTM A266 forgings shall be heat treated by one of the four processes: annealing, normalizing, normalizing and tempering, or liquid quenching and tempering. When tempering is performed, it shall be at a subcritical temperature, but no less than 1100°F [595°C].

"N" refers to "Normalization", which is a heat treatment process used to enhance the mechanical properties of the material, such as its strength and toughness. During normalization, the material is heated to a specific temperature, typically above the transformation range, and then cooled in air. This process helps to refine the grain structure, improve uniformity, and relieve internal stresses in the material.

Advantages of Forged Flanges

-

Strength: Superior mechanical properties due to forged grain structure.

-

Safety: Reduced risk of leaks or failures in critical systems.

-

Precision: Tight dimensional tolerances for proper alignment.

-

Longevity: Resistant to fatigue, creep, and thermal cycling.

Application

Forged body flanges are widely used in industries requiring reliability under harsh conditions:

-

Oil & Gas: Pipeline connections, wellheads, refinery equipment.

-

Chemical/Petrochemical: Reactors, heat exchangers, and storage tanks.

-

Power Generation: Boilers, turbines, and steam systems.

-

Marine/Offshore: Subsea pipelines and shipboard systems.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!