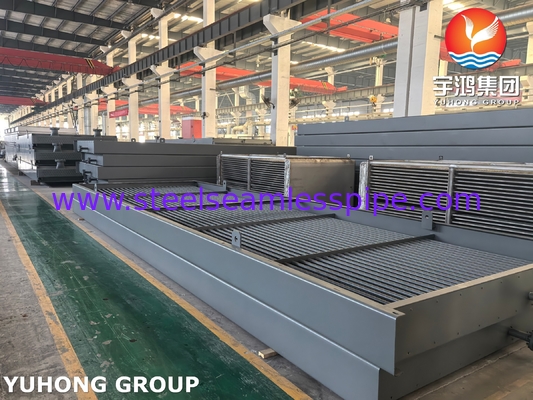

Air Cooler Heat Exchanger API 661 For Power Generation Plants ISO 13706

Industrial air coolers heat exchanger, also known as forced-draft air coolers (FDAC) or evaporative coolers, they are widely used in large-scale projects requiring efficient, cost-effective heat dissipation.

Some Common Key Projects

Industrial air coolers heat exchnager typically occurs in the following types of projects:

Power Generation Plants, Focus: High-temperature resistance, corrosion protection (for coastal plants,ect.)

Thermal Power Plants

1.Direct Air-Cooled Condensers (ACC) ,for steam turbine exhaust cooling (replacing water-cooled condensers).

2.Auxiliary Cooling for pumps, compressors, and transformers.

Gas Turbine Power Plants

1.Inlet Air Cooling, increases efficiency by lowering intake air temperature.

Nuclear & Renewable Energy Plants

1.Waste Heat Rejection, used in dry cooling systems for solar thermal or nuclear plants.

Oil & Gas / Petrochemical Industry, Key Requirements:Explosion-proof design (ATEX certification), chemical-resistant materials (e.g., stainless steel 316L)

Refineries

1.Cooling for distillation columns, reactors, and heat exchangers.

Chemical Plants (Ethylene, Fertilizers, etc.)

1.Process cooling for compressors and reactors.

LNG Terminals

1.Cooling boil-off gas (BOG) recondensation systems.

Metallurgy & Heavy Manufacturing, Key Technical Requirements:Dust-proof filters, high-temperature fan systems (>150°C)

Steel Mills

1.Blast furnace cooling, continuous casting machine cooling.

Aluminum & Copper Smelting

1.Electrolytic cell cooling, flue gas heat recovery.

Cement Plants

1.Rotary kiln and grate cooler cooling.

An air cooler is a euipment that cools air through the evaporation of water. Their advantage is that unlike traditional air conditioners that use refrigerants and compressors, air coolers are more energy-efficient and environmentally friendly. They work best in hot, dry climates where humidity is low.

Key Advantages

Energy Efficiency: fans consume less power than water-cooled systems.

Low Maintenance: unlike cooling towers,no need water treatment.

Dry Operation: ideal for water-scarce regions.

Modular Design: easy to scale for large industrial loads.

Air Cooler Heat Exchanger Works

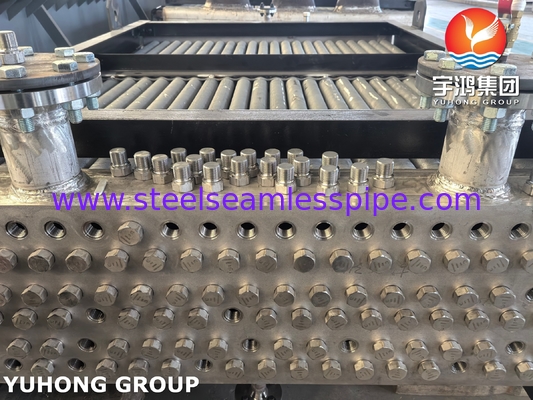

The core components: finned tubes(embedded G finned tubes or extruded finned tubes,etc.); forced-draft fans; header/manifold; support structure (steel frame to withstand wind or loads).

Note about finned tubes: Aluminum fins for corrosion resistance, stainless steel for harsh chemicals.

Working Principle

1. Hot Process Fluid Enters: The fluid (water, oil, steam, or chemicals,ect.) flows through the tubes.

2. Forced-Draft Fans Blow Air: Fans actively push ambient air across the finned tube.

3. Heat Exchange Occurs: Air absorbs heat from the tubes via conduction/convection.Fins amplify surface area for faster cooling.

4. Cooled Fluid Exits: The process fluid leaves at a lower temperature, ready for reuse.

5. Hot Air Discharged: Warm exhaust air is released to the atmosphere.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!