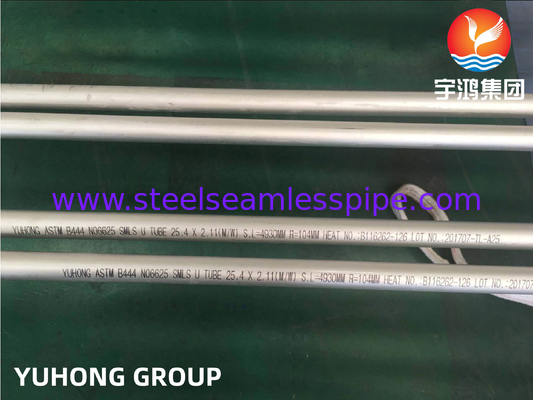

Inconel 625 , Nickel Alloy Seamless U Tube ASTM B444 UNS NO8825 For Heat Exchanger

ASTM B444 specifies the requirements for nickel-alloy seamless pipes and tubes, with UNS N08825 (commonly known as Incoloy 825) being a high-performance material designed for aggressive environments. This alloy combines excellent corrosion resistance with mechanical strength, making it suitable for demanding industrial applications.

Inconel 625 Seamless U Tube Composition:

Nickel (Ni): 38-46% (provides corrosion resistance).

Chromium (Cr): 19.5-23.5% (enhances oxidation resistance).

Iron (Fe): Remainder (base metal).

Molybdenum (Mo): 2.5-3.5% (resists pitting/crevice corrosion).

Copper (Cu): 1.5-3.0% (improves resistance to sulfuric acid).

Titanium (Ti): 0.6-1.2% (stabilizes against sensitization during welding).

Carbon (C): ≤0.05% (minimizes carbide precipitation).

Other elements (Mn, Si, S) are controlled to low levels for optimal performance.

Inconel 625 Seamless U Tube Manufacturing:

Produced via extrusion or rotary piercing, seamless tubes ensure superior pressure integrity and uniformity, ideal for high-stress applications. The process avoids weld seams, enhancing reliability in corrosive or high-pressure environments.

Inconel 625 Seamless U Tube Key Properties:

Tensile Strength: ≥586 MPa.

Yield Strength: ≥241 MPa.

Elongation: ≥30% (ensures ductility).

Heat Treatment: Solution annealed at 925-1025°C followed by rapid cooling to optimize microstructure.

Corrosion Resistance: Excels in both oxidizing (e.g., nitric acid) and reducing (e.g., sulfuric, phosphoric acids) environments. Resists stress-corrosion cracking, chloride-induced pitting, and marine atmospheres.

Inconel 625 Seamless U Tube Applications:

- Sulfuric acid production: Used in acid concentrators, piping, and heat exchangers (resists corrosion up to 40% concentration at elevated temperatures).

- Phosphoric acid evaporators: Handles hot, highly corrosive slurries during fertilizer production.

- Chlorinated solvents production: Reactors and condensers exposed to chlorine, chlorides, and organic acids.

- Subsea pipelines: Flowlines and umbilicals for seawater injection or corrosive hydrocarbon transport.

- Refinery heat exchangers: Tubes for crude oil preheaters and sulfur recovery units (resists sulfidation).

- Seawater cooling systems: Condenser and heat exchanger tubes in desalination plants, ships, and offshore platforms.

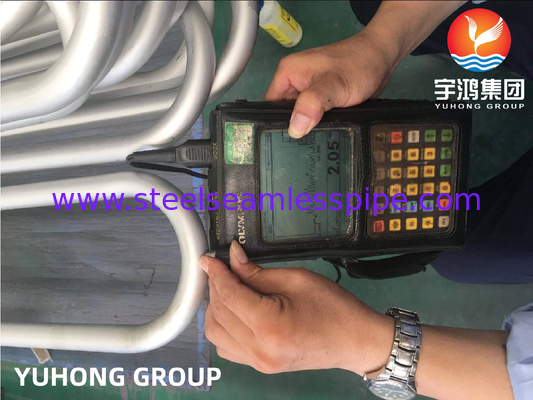

Inconel 625 Seamless U Tube Standards Compliance:

Meets ASTM B444 for chemical, mechanical, and dimensional requirements.

Compatible with ASME SB444 for pressure vessel use.

Non-destructive testing (NDT) and hydrostatic testing ensure quality.

Inconel 625 Seamless U Tube Advantages:

Superior performance in extreme temperatures (up to 540°C).

Seamless construction enhances safety in high-pressure systems.

Versatile in multiphase corrosive environments.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!