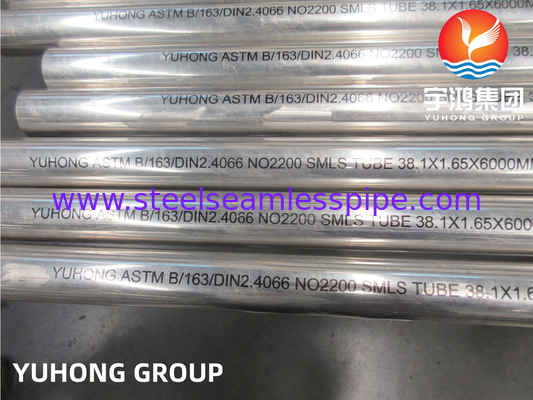

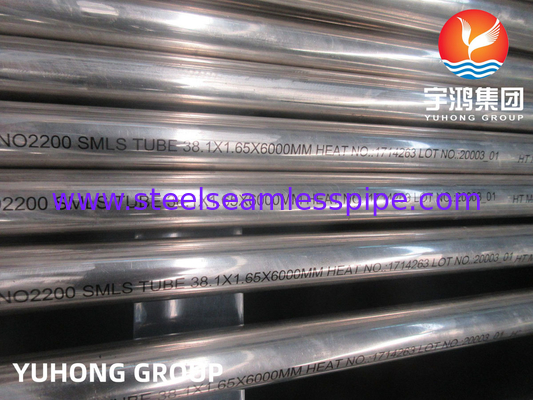

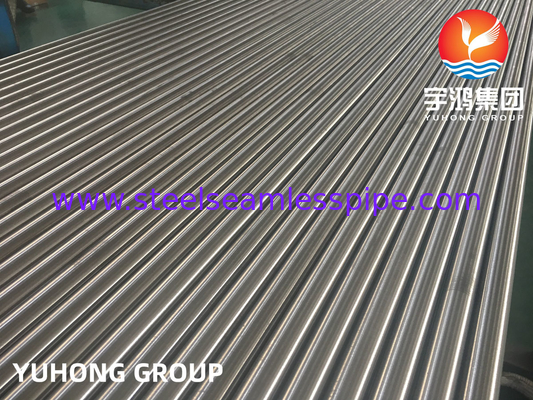

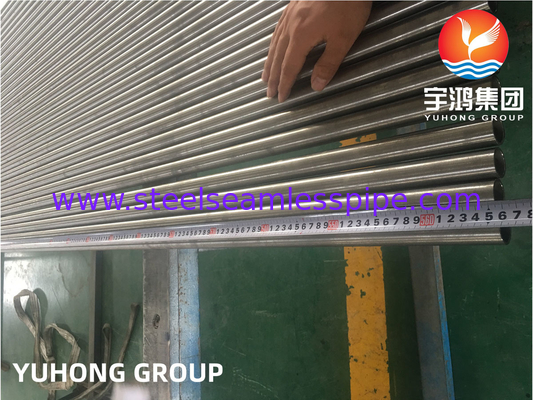

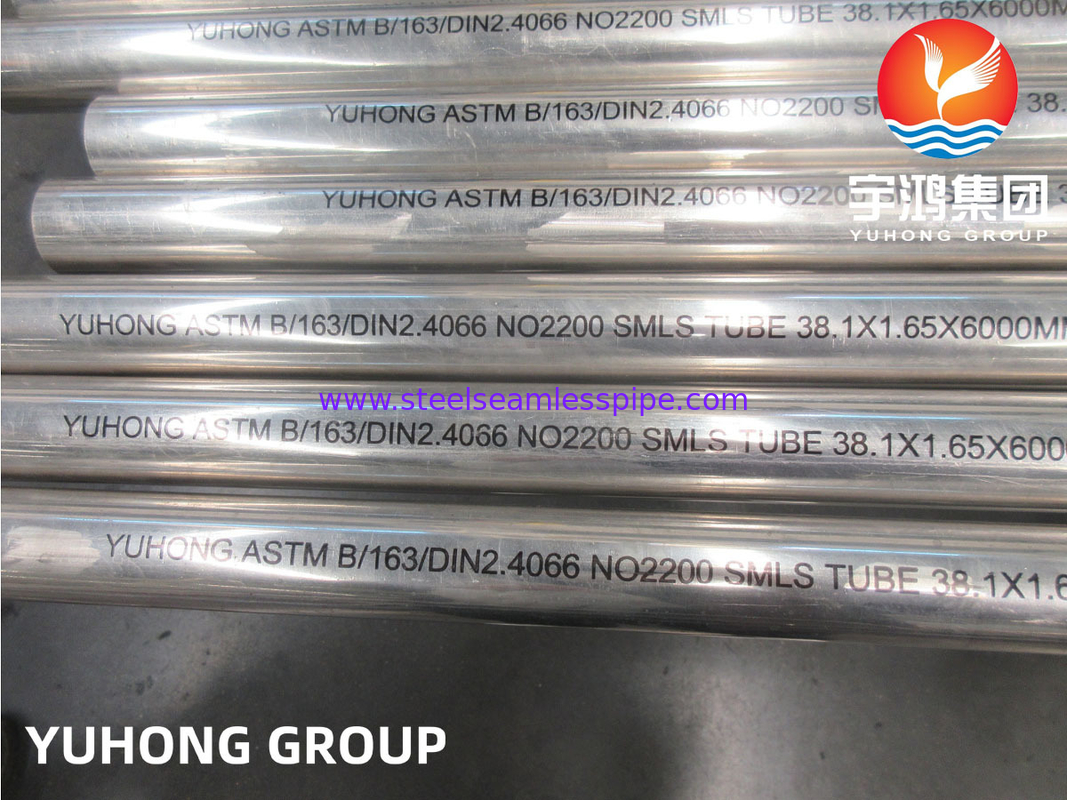

ASTM B163 N02200 Nickel Alloy Seamless Condenser And Heat Exchanger Tubes

YUHONG Group can offer ASTM B163 / ASME SB163 N02200 SMLS nickel alloy tubes.

ASTM B163 This specification covers seamless tubes of nickel and nickel alloys, for use in condenser, heat-exchanger and other industrial service.

UNS N02200 (Alloy 200) is a commercially pure (99.0% min) wrought nickel. Below are key characteristics of N02200 seamless tubes:

Excellent Corrosion Resistance: Resists corrosion in a wide range of reducing and neutral media, including fresh water, natural waters, non-oxidizing salts, and alkaline solutions. It is particularly resistant to caustic alkalies.

High Thermal and Electrical Conductivity: Higher than most nickel alloys.

Good Mechanical Properties: Maintains good strength and ductility from cryogenic temperatures up to moderately high temperatures.

Testing and Inspection

Hydrostatic Test (or Nondestructive Electric Test)

Flattening Test,Reverse Flattening Test

Flaring Test

Hardness Test

Tension Tests

Chemical Analysis

Chemical Composition % Alloy 200 / UNS N02200

| Nickel |

Copper |

Iron |

Manganese |

Carbon |

Silicon |

Sulfur |

| 99.0 min |

0.25 max |

0.40 max |

0.35 |

0.15max |

0.35 |

0.01 |

Nickel element shall be determined arithmetically by difference.

Mechanical Property Alloy 200 / UNS N02200

| Condition |

Tensile Strength min |

Yield Strength min |

Elongation (%) |

Rockwell Hardness |

| annealed |

55ksi (379MPa) |

15ksi (103MPa) |

40 min |

/ |

| stress-relieved |

65ksi (448MPa) |

40ksi (276MPa) |

15 min |

B65 max |

Rockwell or equivalent hardness values apply only to the annealed ends of stress-relieved tubing. Caution should be observed in using the Rockwell test on thin material, as the results may be affected by the thickness of specimen.

Applications Industries

Heat exchangers, evaporator tubes, distillation columns, and piping for handling caustic soda (sodium hydroxide) and other alkalies, organic chemicals, and food processing.

Components requiring reliability in corrosive environments about aerospace and defense.

Condenser tubes and other components exposed to seawater and marine atmospheres.

Feedwater heaters and other systems in power generation.

Components requiring high purity and conductivity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!