- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

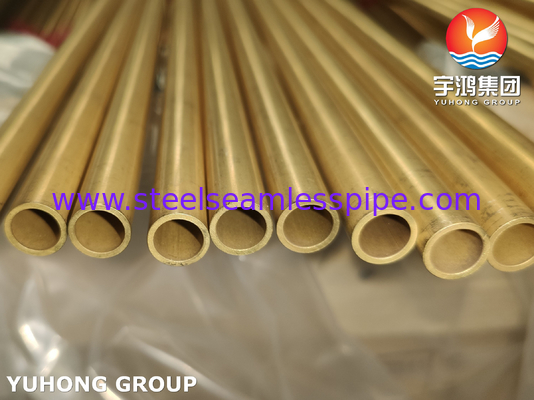

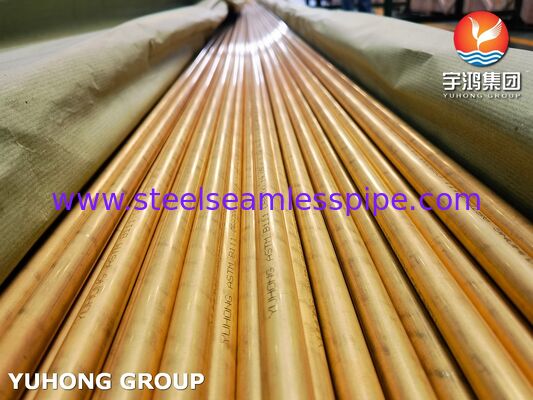

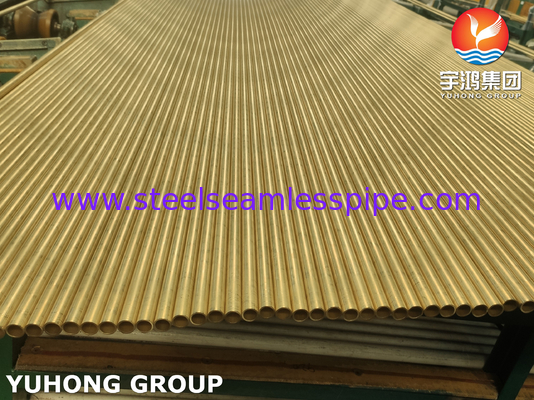

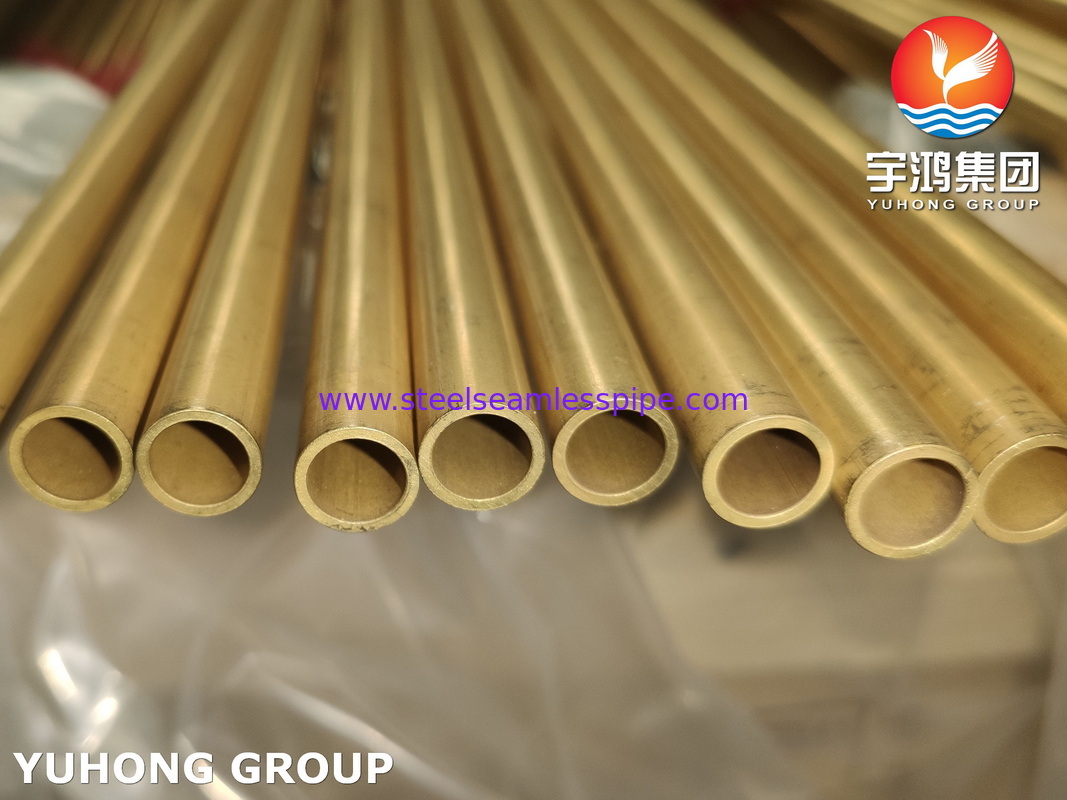

ASTM B111 C68700 Copper-Alloy Seamless Tube For Condenser and Heat Exchanger Tube Bundle

ASTM B111 C68700 is a high-performance arsenical aluminum brass (CuZn20Al1As) seamless tube specifically engineered for critical heat transfer applications in condensers, heat exchangers, and other thermal systems. This alloy combines copper (Cu), zinc (Zn), aluminum (Al), and a controlled arsenic (As) addition to achieve superior corrosion resistance, erosion resistance, and thermal conductivity, particularly in marine, power plant, and industrial cooling systems.

1.Chemical & Mechanical Properties

| ASTM B111 C68700 Chemical Composition (%) |

| Cu |

Al |

Fe |

Zn |

As |

Mo |

| 76.0-79.0% |

1.8-2.5% |

≤0.06% |

REM |

0.02-0.06% |

/ |

Mechanical Properties

| Property |

Standard Value (Annealed) |

| Tensile Strength |

≥ 380 MPa |

| Yield Strength |

≥ 140 MPa |

| Elongation |

≥ 30% |

| Hardness (Brinell) |

≤ HRB 65 |

2. Key Adventages

- Superior Corrosion Resistance

Dezincification Resistance: Arsenic (As) addition prevents dezincification in seawater and aggressive cooling media.

Erosion-Corrosion Resistance: Aluminum (Al) oxide layer resists impingement attack in high-velocity flows (>3 m/s).

-

Excellent Thermal Conductivity

Thermal conductivity ~100 W/m·K, close to pure copper, far surpassing stainless steel (15 W/m·K) and titanium (22 W/m·K).

Smooth seamless interior minimizes fouling, ensuring sustained heat transfer efficiency.

-

High Strength & Fabrication Flexibility

Cold-work hardening: Tensile strength can reach 650 MPa (hard temper) via cold drawing.

Annealed temper (O61) allows tube bending/flaring for complex heat exchanger layouts.

-

Long Service Life & Low Maintenance

Service life exceeds 20 years in seawater (3~5x longer than carbon steel).

No need for cathodic protection or coatings, reducing lifecycle costs.

3. Key Applications

Thermal power plant condensers: Resists high-pressure steam, ammonia attack, and sulfide corrosion

Nuclear plant heat exchange systems: Used in secondary cooling loops, resists chloride-induced corrosion

- Marine & Offshore Engineering

Marine central coolers: Resists seawater corrosion and biofouling, reduces maintenance

Desalination plants: Withstands high-salinity media, maintains heat transfer performance

Refinery heat exchangers: Resists H₂S and acidic fluid corrosion

LNG liquefaction equipment: Maintains ductility in cryogenic conditions (above -40°C)

- Industrial Refrigeration & HVAC

Industrial chillers: High thermal conductivity reduces energy consumption

Lithium bromide absorption chillers: Resists LiBr solution corrosion, service life >15 years

| Performance |

C68700

(Arsenical Aluminum Brass)

|

C71500

(Cu-Ni 70/30)

|

C70600

(Cu-Ni 90/10)

|

C44300

(Admiralty Brass)

|

| Composition |

Cu-Zn20-Al1-As0.04 |

Cu-30Ni-0.7Fe |

Cu-10Ni-1.4Fe |

Cu-Zn28-Sn1-As0.04 |

| Thermal Conductivity (W/m·K) |

100 |

29 |

50 |

110 |

| Seawater Corrosion Resistance |

★★★★★

(anti-dezincification)

|

★★★★★

(all-round)

|

★★★★☆

(better than 90/10)

|

★★★☆☆

(requires inhibitor)

|

| Acid Resistance |

★★★☆☆ (pH≥6) |

★★★★★

(resists H₂S/CO₂)

|

★★★★☆ |

★★☆☆☆ |

| Erosion-Corrosion Resistance |

★★★★☆

(Al oxide layer)

|

★★★★★ |

★★★★☆ |

★★☆☆☆ |

| Max Operating Temp (°C) |

200 (short-term 260) |

300 |

260 |

150 |

| Low-Temperature Toughness |

Good above -40°C |

Stable at -196°C |

Stable at -100°C |

Good above -40°C |

| Cost Index |

$$$ (moderate) |

$$$$$ (highest) |

$$$$ |

$$ (lowest) |

| Typical Applications |

Seawater condensers, marine heat exchangers |

Offshore platforms, LNG equipment |

Desalination plants, chemical exchangers |

Freshwater coolers, HVAC |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!