ASTM B366 Alloy C22 (UNS N06022) Butt Weld Elbows | Superior Corrosion Resistant Nickel Alloy Fittings

Introduction: The Pinnacle of Corrosion Resistance in Nickel Alloy Elbows

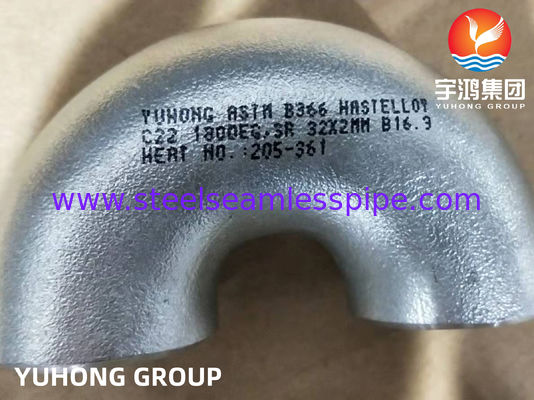

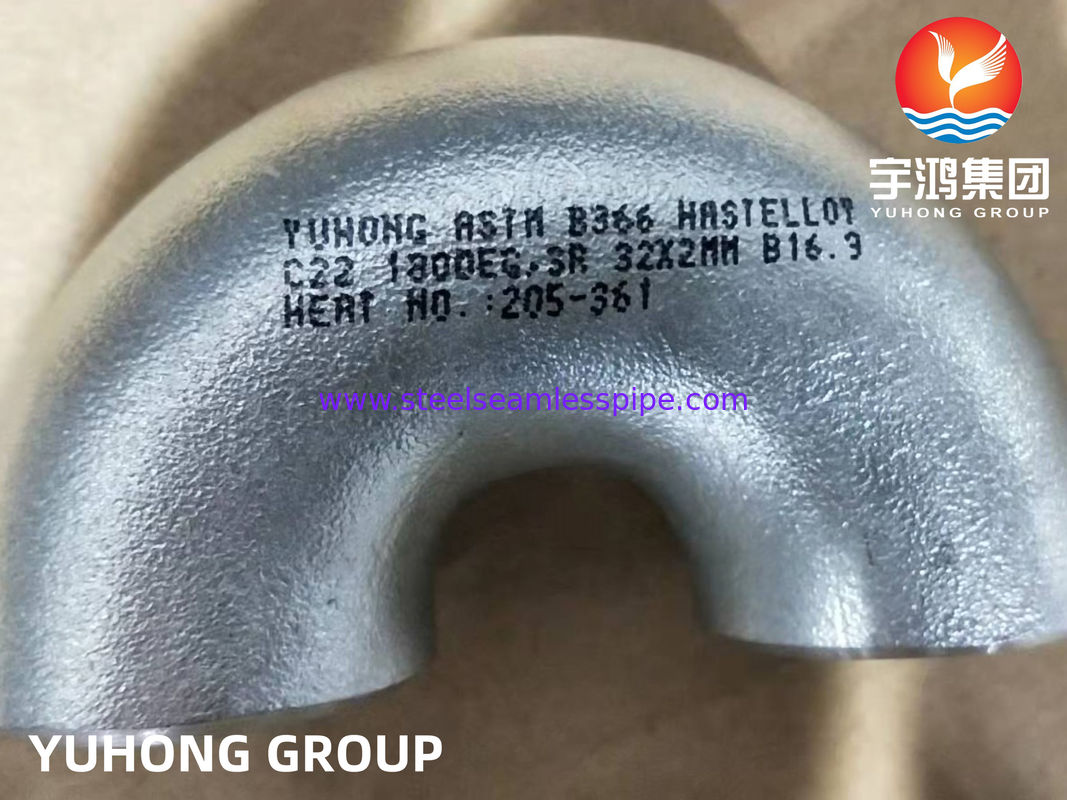

Alloy C22 (UNS N06022) Butt Weld Elbows manufactured to ASTM B366 represent the gold standard in corrosion resistance for demanding industrial piping systems. This nickel-chromium-molybdenum-tungsten alloy offers exceptional performance in oxidizing and reducing environments, handling chlorides, acids (including sulfuric, hydrochloric, phosphoric), and mixed acid/salt solutions where lesser alloys fail. Our precision elbows ensure leak-free flow direction changes in critical applications worldwide.

Alloy C22 Chemical Composition: Engineered for Maximum Stability

The outstanding corrosion resistance of C22 elbows stems from its tightly controlled, balanced chemistry:

Table 1: ASTM B366 Alloy C22 (UNS N06022) Typical Chemical Composition (Weight % Maximum Unless Noted)

| Element |

Nickel (Ni) |

Chromium (Cr) |

Molybdenum (Mo) |

Tungsten (W) |

Iron (Fe) |

Cobalt (Co) |

Carbon (C) |

Manganese (Mn) |

Silicon (Si) |

| Requirement |

Balance |

20.0 - 22.5 |

12.5 - 14.5 |

2.5 - 3.5 |

2.0 - 6.0 |

≤ 2.5 |

≤ 0.015 |

≤ 0.50 |

≤ 0.08 |

Key: This precise Ni-Cr-Mo-W balance creates a highly stable passive film, resisting pitting, crevice corrosion, and stress corrosion cracking (SCC).

Alloy C22 Equivalent Grades: Global Material Recognition

C22 elbows are specified under various international standards for identical/similar corrosion performance:

Table 2: Alloy C22 (UNS N06022) International Equivalent Specifications

| Standard System |

UNS |

EN (Europe) |

W.Nr. (DIN) |

ISO |

JIS (Japan) |

GOST (Russia) |

Common Trade Names |

| Designation |

N06022 |

NiCr21Mo14W |

2.4602 |

NW 6022 |

NW 6022 |

ХН60МВЮ |

Hastelloy® C-22, INCONEL® alloy 622 |

Note: Equivalency indicates similar corrosion performance; verify specific standard requirements for interchangeability.

Alloy C22 Mechanical Properties: Strength Meets Fabricability

C22 maintains excellent mechanical properties even in aggressive service conditions:

Table 3: ASTM B366/B564 Alloy C22 Typical Room Temperature Mechanical Properties (Wrought & Annealed Condition)

| Property |

Tensile Strength (min) |

Yield Strength (0.2% Offset, min) |

Elongation (in 2" or 50mm, min) |

Hardness (Rockwell B, max) |

| Requirement |

690 MPa (100 ksi) |

310 MPa (45 ksi) |

40% |

100 HRB |

| Typical Achieved Value |

780-895 MPa (113-130 ksi) |

360-415 MPa (52-60 ksi) |

55-65% |

75-90 HRB |

Key: High ductility (Elongation) ensures good formability for elbows, while strength exceeds most corrosive service needs.

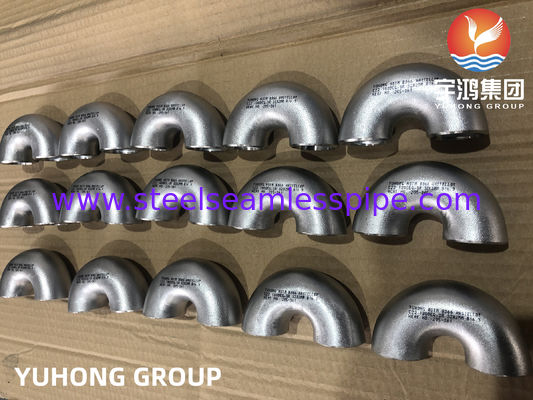

Alloy C22 Elbow Product Range: Precision Formed for Critical Service

We supply the full spectrum of ASTM B366 C22 butt weld elbows for seamless system integration:

- Types: 90° Elbows (LR & SR), 45° Elbows, 180° Returns (LR & SR)

- Dimensions: ASME B16.9 / MSS SP-43 (Standard), ASME B16.28 (Butt Weld Short Radius)

- Sizes: 1/2" NB (DN15) to 48" NB (DN1200)

- Wall Thickness: SCH 5S, SCH 10S, SCH 40S, SCH 80S, SCH 160S, XXS; Also available per customer specified thickness (WT).

- Manufacturing Process: Seamless (SMLS) or Welded & Solution Annealed (mandatory for corrosion resistance).

- Ends: Beveled ends (ASME B16.25) ready for welding.

Alloy C22 Elbow Dimensional Tolerances: Precision Guaranteed

Our elbows conform to strict dimensional standards ensuring fit-up and weld integrity:

Table 4: Key Dimensional Tolerances per ASME B16.9 for Alloy C22 Elbows

| Parameter |

Tolerance |

| Center-to-End (90° LR) |

±1.6mm (1/16") for NPS ≤ 24", ±3.2mm (1/8") for NPS > 24" |

| Center-to-End (90° SR) |

±1.6mm (1/16") for all NPS |

| Center-to-End (45°) |

±1.6mm (1/16") for NPS ≤ 24", ±3.2mm (1/8") for NPS > 24" |

| Out of Roundness (Ovality) |

1% of Nominal OD max (after welding prep) |

| Wall Thickness |

±12.5% of ordered nominal wall (subject to mill tolerance of raw pipe/tube) |

| Bevel Angle |

37.5° ± 2.5° |

| Bevel Land (Face) |

1.6mm ± 0.8mm (1/16" ± 1/32") |

Alloy C22 Elbow Applications: Conquering the Most Aggressive Environments

These elbows excel where corrosion resistance is paramount:

- Chemical Processing: Reactors, mixers, piping for HCl, H2SO4, H3PO4, acetic acid, chlorine, solvents.

- Pollution Control (FGD/Scrubbers): Ducts, headers, mist eliminators, absorber towers handling hot, wet SO2/Cl⁻/F⁻.

- Pharmaceutical: High-purity process lines, CIP/SIP systems requiring contamination resistance.

- Pulp & Paper: Bleach plants (chlorine dioxide, hypochlorite), digesters, liquor lines.

- Waste Incineration & Treatment: Flue gas, ash slurry, and leachate handling systems.

- Marine & Offshore: Seawater cooling, ballast water treatment, chemical injection.

- Nuclear Fuel Reprocessing: Handling nitric acid and fission products.

- Acid Mining & Metal Refining: Electrowinning, pickling, electrolyte handling.

Why Choose Our ASTM B366 Alloy C22 Elbows?

- Material Integrity: Mill Test Certificates (MTCs) per EN 10204 3.1/3.2 guaranteeing full traceability and compliance.

- Precision Manufacturing: Strict adherence to ASME B16.9/B16.28 dimensional tolerances for perfect fit-up.

- Optimal Corrosion Resistance: Solution annealing per ASTM B366 ensures maximum alloy performance.

- Global Availability: Stocked in key sizes; custom orders fulfilled promptly.

- Technical Expertise: Engineering support for material selection and application suitability.

Order Your Corrosion-Resistant Solution Today!

Request a quote for ASTM B366 Alloy C22 (UNS N06022) Butt Weld Elbows in your required size, schedule, and quantity. Specify angle (90°/45°/180°) and radius (LR/SR).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!