- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

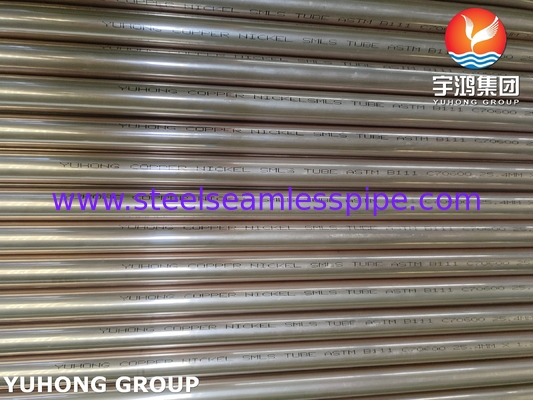

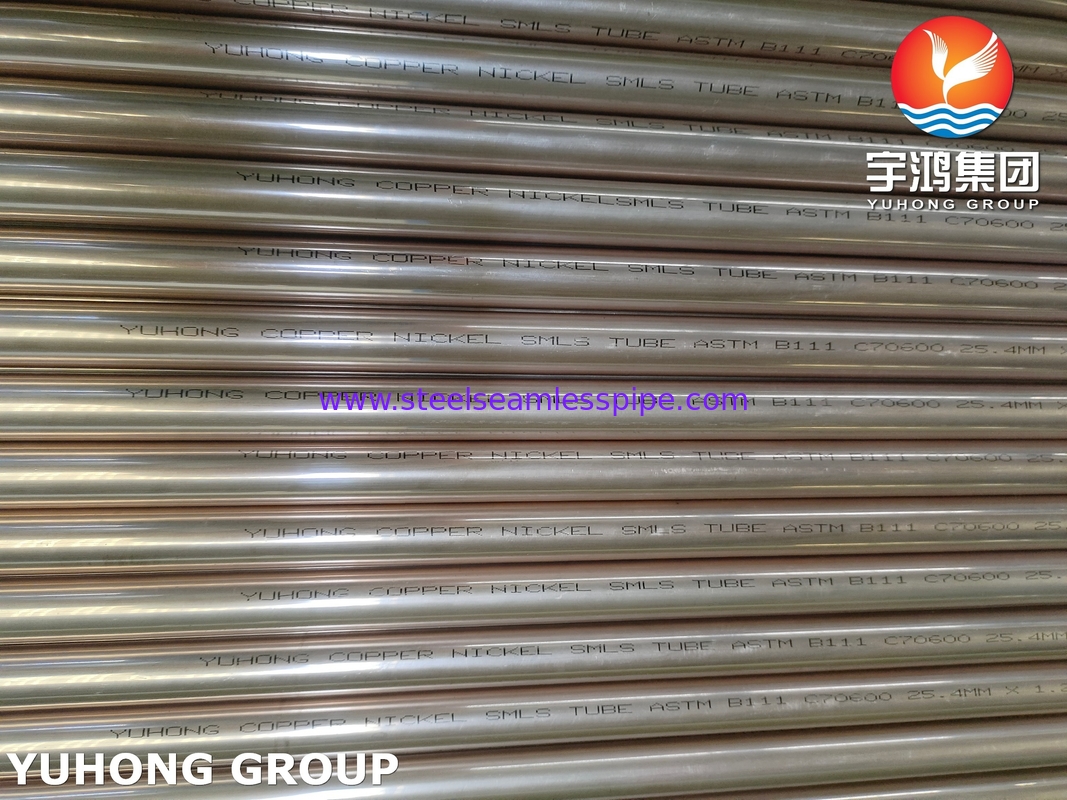

ASTM B111 C70600 Seamless 90-10 Copper Nickle Alloy Steel Tube For Water Treatment

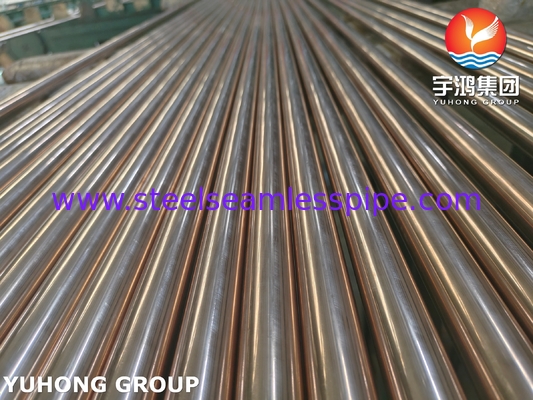

ASTM B111 C70600 is a specification for seamless tubes fabricated from a 90-10 copper-nickel alloy (UNS C70600), which contains approximately 90% copper and 10% nickel, along with small additions of iron(1%-1.8%) and manganese(≤1%) for enhanced strength and corrosion resistance. This product refers to tubes that are manufactured through a seamless extrusion and drawing process, ensuring a homogeneous structure without welded seams.

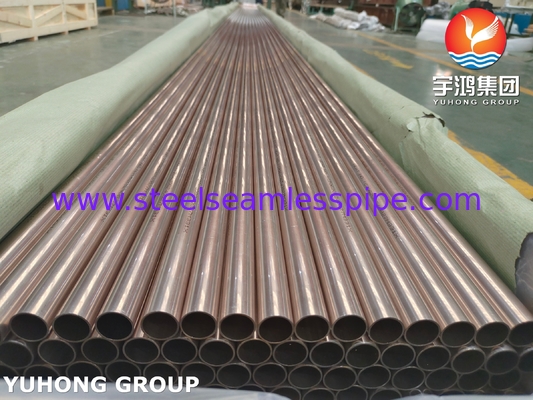

These tubes are specifically engineered for water treatment applications, particularly in demanding environments involving raw, brackish, or seawater. The alloy's inherent properties provide exceptional resistance to corrosion, erosion, impingement attack, and biofouling, ensuring long service life and reliability in heat exchangers, condensers, desalination units, and various water conveyance systems.

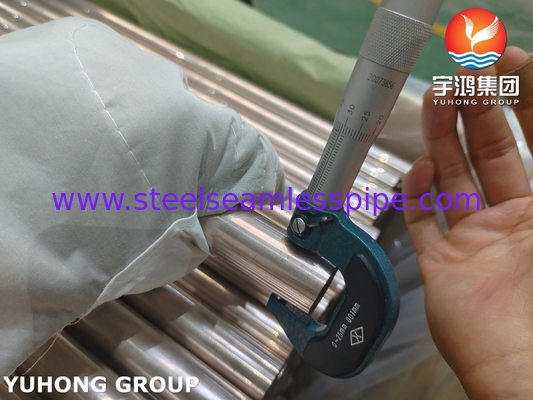

1.Chemical & Mechanical Properties

| ASTM B111 C68700 Chemical Composition (%) |

| Cu (Ag) |

Ni |

Pb |

Fe |

Zn |

Mn |

| Rem |

9.0%-11.0% |

≤0.05% |

1.0%-1.8% |

≤1.0% |

≤1.0% |

Mechanical Properties

| Property |

Standard Value |

Tensile Strength

|

O61 Annealed ≥ 40ksi |

| H55 Light-drawn ≥ 45ksi |

Yield Strength

|

O61 Annealed ≥ 15ksi |

| H55 Light-drawn ≥ 35ksi |

| Elongation |

≥ 30% |

| Hardness |

O61 Annealed 40-65 HRB |

2. Key Adventages

- Excellent Resistance to Seawater Corrosion

The alloy effectively resists uniform corrosion, pitting, crevice corrosion, and impingement attack caused by high-velocity seawater. This is its most fundamental advantage.

- Outstanding Biofouling Resistance

The slow release of copper ions effectively prevents marine organisms (such as barnacles, algae) from adhering to and growing on the inner pipe wall, reducing maintenance needs and maintaining flow efficiency.

- Good Workability and Formability

Annealed tubes have high ductility and are easily bent, flared, flanged, and welded, facilitating on-site installation and the construction of complex piping systems.

- Superior Resistance to Stress Corrosion Cracking (SCC)

Compared to some other alloys (such as certain stainless steels), 90-10 CuNi has high resistance to stress corrosion cracking in chloride environments, offering greater reliability.

- Long Service Life and High Reliability

Its combined corrosion and erosion resistance ensures a very long service life in harsh marine and industrial environments, reducing the total cost of ownership.

3. Key Applications

- Shipbuilding and Marine Engineering: Seawater cooling systems, firefighting systems, ballast water systems, bilge water systems, and fuel oil piping on ships and vessels.

- Offshore Oil and Gas Platforms: Seawater cooling pipes, firewater mains, water injection lines, and various process piping on offshore platforms.

- Desalination Plants: Heat exchanger tubes, evaporator tubes, and brine heater tubes in Multi-Stage Flash (MSF) and Multi-Effect Distillation (MED) plants.

- Power and Energy Industry: Power station condenser tubes, and piping for handling corrosive fluids in geothermal energy systems.

- Chemical and Process Industries: Fabrication of evaporators, heat exchangers, and condensers for handling salt solutions, brines, and other corrosive chemicals.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!