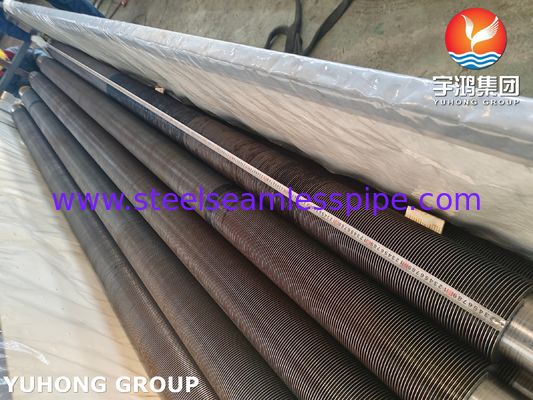

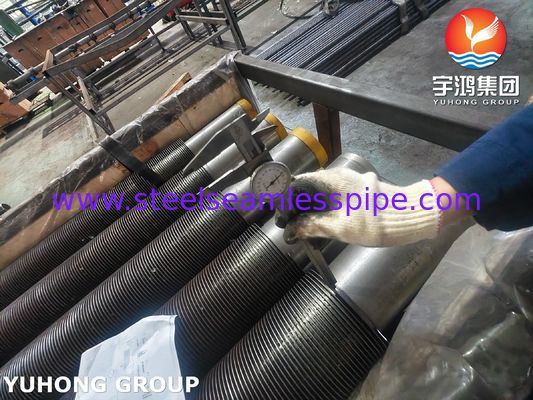

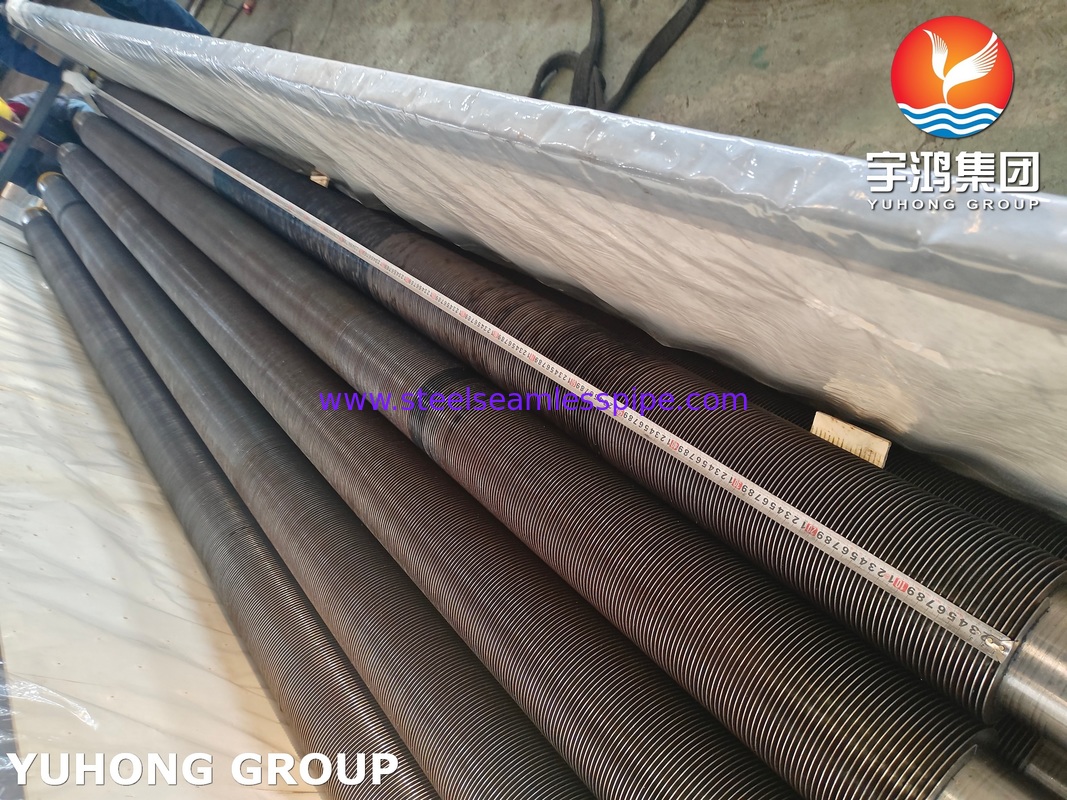

ASME SA312 TP321H High-Frequency Welded (HFW) Fin Tube

The ASME SA312 TP321H High-Frequency Welded (HFW) Fin Tube is a high-performance heat transfer component engineered for extreme industrial environments. It combines the superior high-temperature strength and corrosion resistance of ASME SA312 TP321H stainless steel with the exceptional thermal efficiency of integrally welded fins. This makes it a critical solution in demanding applications across power generation, petrochemical, and process heating industries.

321H is a high-carbon austenitic stainless steel grade: the "H" denotes high carbon content (0.04–0.10%), which enhances high-temperature strength.Key Alloying Element: Titanium (Ti). This is the crucial stabilizer that prevents chromium carbide precipitation during exposure to high temperatures (450-900°C / 842-1652°F), which causes sensitization and intergranular corrosion.

Chemical Composition(%)

| TP321H Chemical Composition(%) |

| Element |

C |

Si |

Cr |

Mn |

Ni |

Ti |

| Range |

0.04-0.10 |

≤0.75 |

17.00-19.00 |

≤2.00 |

9.00-123.00 |

4*C-0.7 |

Mechanical Properties

| ASME SA312 TP321H Mechanical Properties |

| Tensile Strength |

Yield Strength |

Hardness |

Elongation |

| 515MPa |

≥205MPa |

≤ 192HB |

≥35% |

Equivalent Material of TP321H

| ASTM/AISI |

UNS NO |

EN |

ISO |

JIS |

GOST |

| TP321H |

UNS32109 |

1.4874 |

X7CrNiTi18-10 |

SUS 321H |

08Ch18N12T |

Advantages of HFW Fin Tubes:

1.Stronger Bond: Metallurgical fusion provides superior resistance to vibration, thermal cycling, and fin peeling.

2.Higher Efficiency: Eliminates air gaps and flux residues, boosting heat transfer by 5–15% over rolled or brazed tubes.

3.Material Flexibility: Welds dissimilar metals (e.g., stainless to carbon steel) without needing ductility or specific alloys.

4.Greater Durability: Withstands high temperatures (800–850°C) and pressure without braze softening or stress cracking.

5.Lower Lifetime Cost: High-speed production and a 2–3x longer service life reduce total cost of ownership.

Applications Of ASME SA312 TP321H High-Frequency Welded (HFW) Fin Tube

1.Power Generation: Boiler superheaters, reheaters, economizers, and air preheaters in coal-fired and combined-cycle plants.

2.Petrochemical & Refining: Heat exchangers in catalytic reforming, hydrocracking, and ethylene pyrolysis furnaces; charge gas coolers.

3.Industrial Furnaces: Convection sections, radiant tubes, and waste heat recovery units in chemical, steel, and glass manufacturing.

4.Waste Heat Recovery Systems: Capturing and repurposing energy from high-temperature exhaust streams.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!