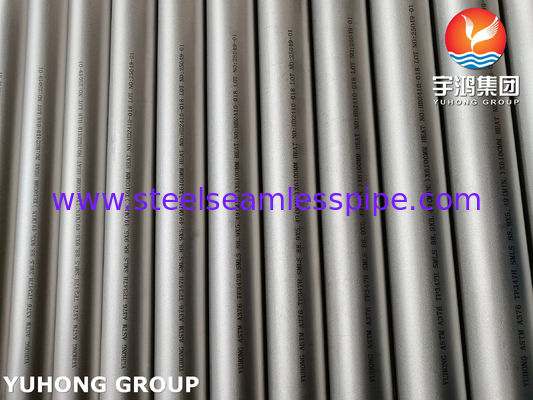

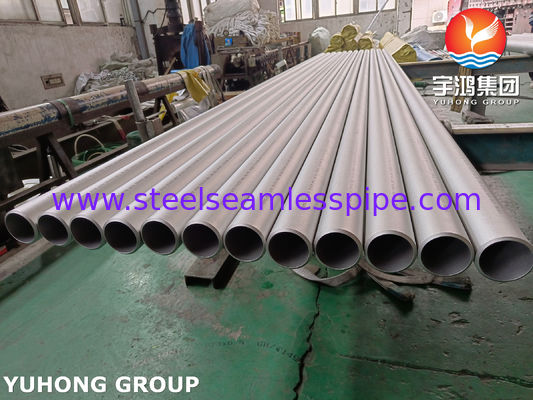

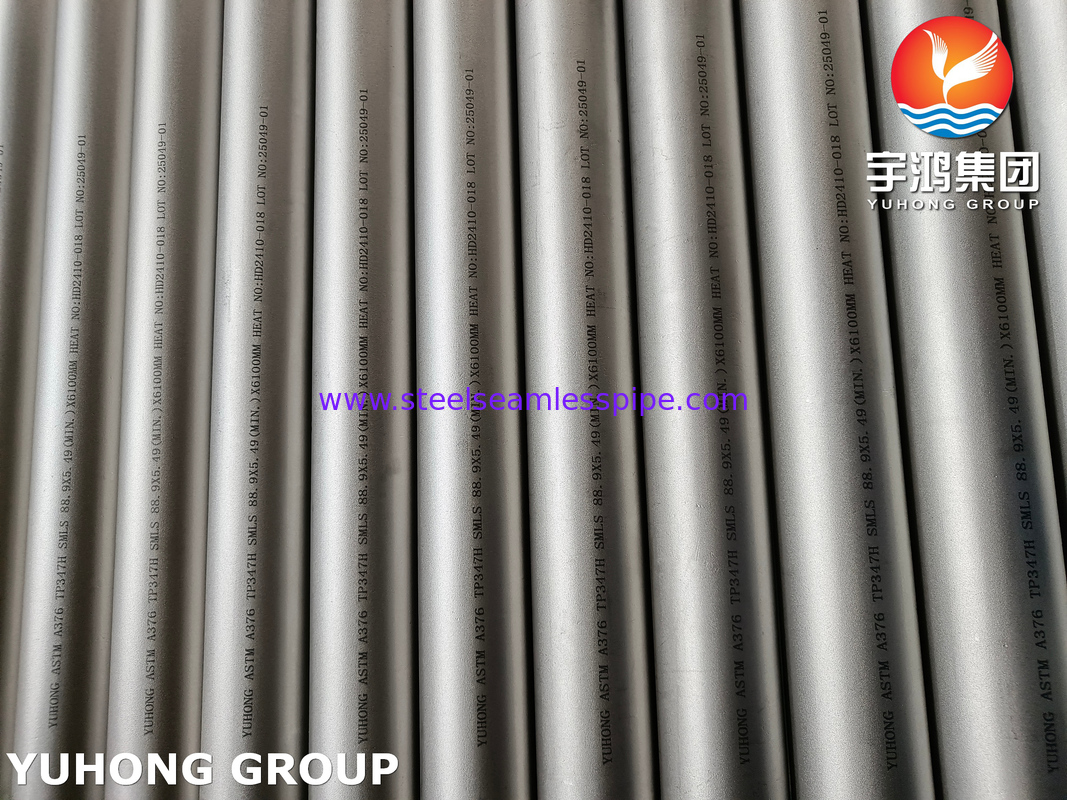

ASTM A376 TP347H Seamless Austenitic Steel Pipe for Power Plant High Temperature Service

YUHONG GROUP specializes in manufacturing high-temperature resistant steel products for critical power generation applications. With over 35 years of expertise in seamless steel pipe production, our ASTM A376 TP347H Seamless Austenitic Steel Pipes deliver exceptional performance in power plant boiler systems.

Chemical Composition of TP347H (UNS S34709)

| Element |

Requirement (%) |

Notes |

| Carbon (C) |

0.04–0.10 |

Controlled for high-temperature stability |

| Manganese (Mn) |

2.00 max |

|

| Phosphorus (P) |

0.045 max |

|

| Sulfur (S) |

0.030 max |

|

| Silicon (Si) |

1.00 max |

|

| Nickel (Ni) |

9.0–13.0 |

Austenite stabilizer |

| Chromium (Cr) |

17.0–19.0 |

Oxidation resistance |

Mechanical Properties of TP347H (UNS S34709)

| Property |

Requirement |

| Grade |

TP347H |

| UNS Designation |

S34709 |

| Tensile Strength, min |

75 ksi [515 MPa] |

| Yield Strength, min |

30 ksi [205 MPa] |

| Elongation in 2 in.., min |

35% (Longitudinal) |

TP347H Testing Requirements Summary

| Category |

Test Type |

Key Requirements |

| Pressure/NDE |

Hydrostatic Test |

Each pipe tested per A999/A999M (except NPS≥24 with NH marking) |

| |

NDE (UT/ET) |

Mandatory for all pipes (manufacturer's method selection) |

| Mechanical |

Tensile Test |

1 test per lot (≤100 pipes); 2 tests for >100 pipes |

| |

Flattening Test |

5% of batch furnace pipes; min. 2 pipes for continuous process |

| Chemical |

Product Analysis |

Required for each pipe length (individual rejection) |

| Special Tests |

Transverse Tension |

Mandatory for NPS≥8 pipes (each end) |

| |

Etching Test |

Checks homogeneity per Method E381 |

| |

Ultrasonic Test |

Full-length scanning with calibration notches |

| |

Intergranular Corrosion |

Practice A262 (as-shipped/sensitized condition) |

ASTM A376 TP347H Seamless Austenitic Steel Pipe - Application Advantages

1. Superior High-Temperature Performance for Power Plants

Excellent creep resistance at temperatures up to 750°C (1382°F) - ideal for superheater and reheater applications

Outstanding oxidation resistance ensures long-term stability in high-temperature flue gas environments

2. Enhanced Safety and Reliability in Critical Systems

Seamless construction provides uniform wall thickness, eliminating weak points under extreme pressure conditions

Nb-stabilized composition prevents intergranular corrosion in continuous high-temperature service

3. Cost-Efficient Power Generation Solution

Extended service life reduces maintenance frequency and replacement costs

Optimized thermal efficiency helps power plants maintain optimal operating parameters

4. Material Characteristics Supporting Power Applications

High temperature strength maintains structural integrity under thermal cycling conditions

Corrosion resistance suitable for various fuel types, including coal, gas, and biomass

5. YUHONG Quality Assurance

Full compliance with ASTM A376/ASME SA376 specifications

Comprehensive testing, including hydrostatic, ultrasonic, and eddy current examinations

Custom sizing available from OD 1/2" to 24" with various schedule thicknesses

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!