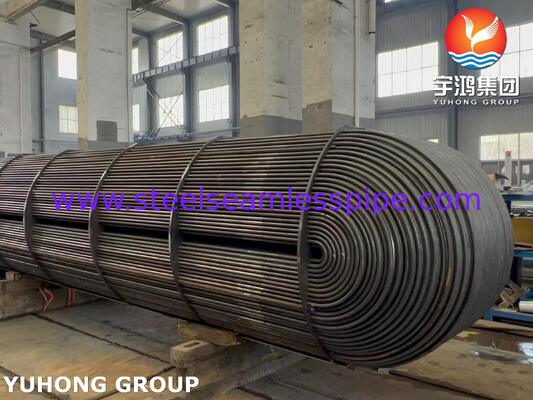

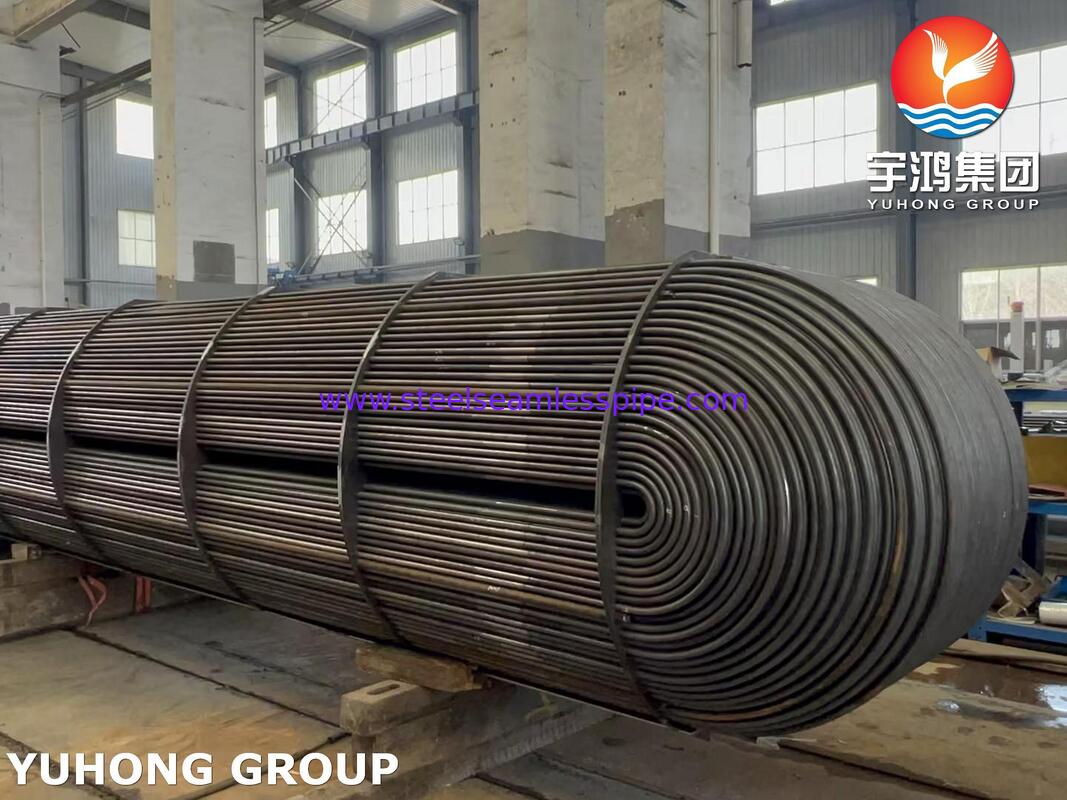

STAINLESS STEEL HEAT EXCHANGER TUBE BUNDLE A179 A213 TUBE WITH TUBESHEET BAFFLE

What is a Tube Bundle?

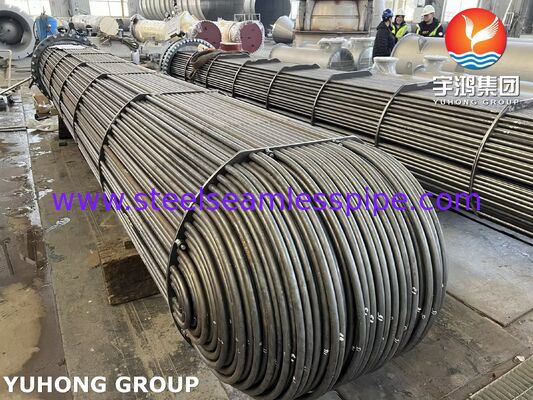

A tube bundle is the core, internal assembly of a shell and tube heat exchanger. It's not the whole exchanger itself, but the removable "heart" of the unit.

A typical tube bundle consists of the following key components, all bundled together:

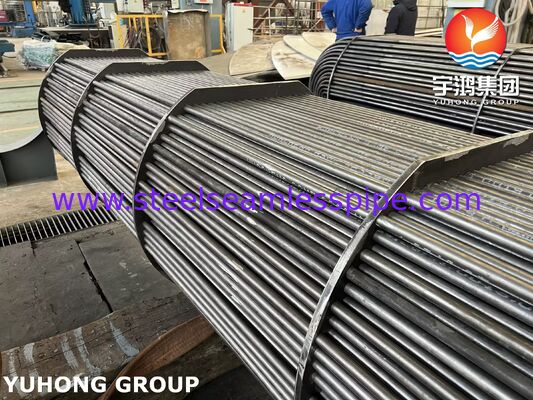

1. Tubes: Hundreds of small-diameter tubes (often made of copper, stainless steel, or titanium) through which one fluid flows. This is the tube-side fluid.

2. Tube Sheets: Thick circular plates at each end of the bundle. The tubes are securely fastened into holes in these sheets (by welding, rolling, or expansion) to prevent the two fluids from mixing.

3. Baffles: A series of plates placed along the length of the bundle. They serve two main purposes:

Support the Tubes: Prevent them from sagging and vibrating.

Direct Fluid Flow: They force the shell-side fluid (the fluid flowing around the outside of the tubes) to take a winding, cross-flow path across the tubes, which increases turbulence and heat transfer efficiency.

4. Spacers & Tie Rods: Long rods that hold the baffles and tube sheets in precise alignment.

The overwhelming primary use of a tube bundle is for efficient and large-scale heat exchange between two fluids while keeping them physically separate. This is critical in countless industrial processes.

How it Works:

One fluid (often the one that needs to be cooled) flows through the tubes. The other fluid (often cooling water or steam) flows on the shell-side, over the outside of the tubes. Heat transfers through the tube walls from the hotter fluid to the cooler fluid.

Key Applications & Industries

Tube bundles are ubiquitous in industries where heating or cooling of process fluids is required:

1. Power Generation:

Surface Condensers: Condense steam exiting a turbine back into water (condensate) using cooling water. This is one of the largest applications.

Feedwater Heaters: Pre-heat boiler feedwater using steam extracted from turbines.

2. Oil Refining & Petrochemical:

Crude Oil Distillation: Heating crude oil before it enters a distillation column.

Product Cooling: Cooling refined products like gasoline, diesel, etc.

Reboilers & Condensers: For distillation columns and chemical reactors.

3. Chemical Processing:

Temperature control for chemical reactions, solvent recovery, and process stream heating/cooling.

4. HVAC & Refrigeration:

Chillers: Large water chillers for district cooling or industrial processes.

Heating Hot Water systems.

5. Marine Industry:

Coolers: For engine jacket water, lubricating oil, and steam systems on ships.

6. Other Industries: Pharmaceutical

Size Range:

| Production |

Outside Diameter |

Wall Thickness |

| Heat Exchanger Tube |

6.00mm to 101.6mm |

0.5mm to 8mm |

Final Finishing

Solution Annealed & Pickled/Bright Annealed.

Type of Tubes:

U-bend & Straight.

Some of the quality tests carried out by us includes:

| Corrosion Test |

Conducted only when specially requested by the client |

| Chemical Analysis |

Test done as per required quality standards |

| Destructive / Mechanical Testing |

Tensile | Hardness | Flattening | Flare | Flange |

| Eddy Current Testing |

Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

| Hydrostatic Testing |

100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

| Visual Inspection |

After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |

Supplementary Testing : Apart from the above mentioned tests, we also carry out on the manufactured products supplementary testing. The tests conducted under this include:

- Eddy Current Testing

- O.P Testing

- Radiography Testing

|

- Corrosion Testing

- Micro Testing

- Macro Testing

|

- IGC Testing

- Ultrasonic testing

- Liquid Penetrate testing

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!