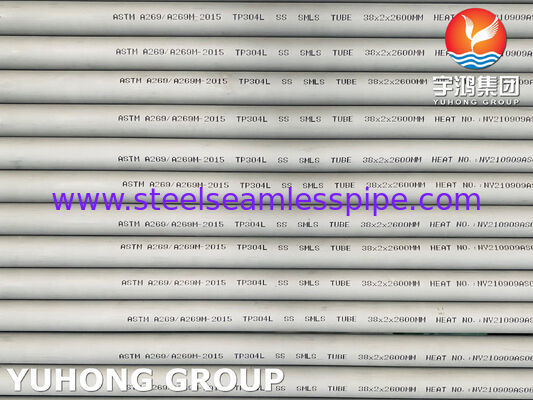

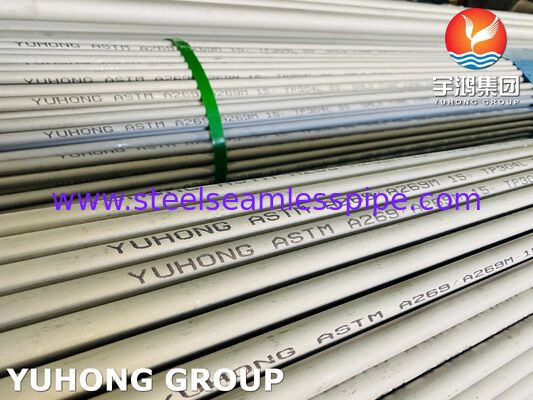

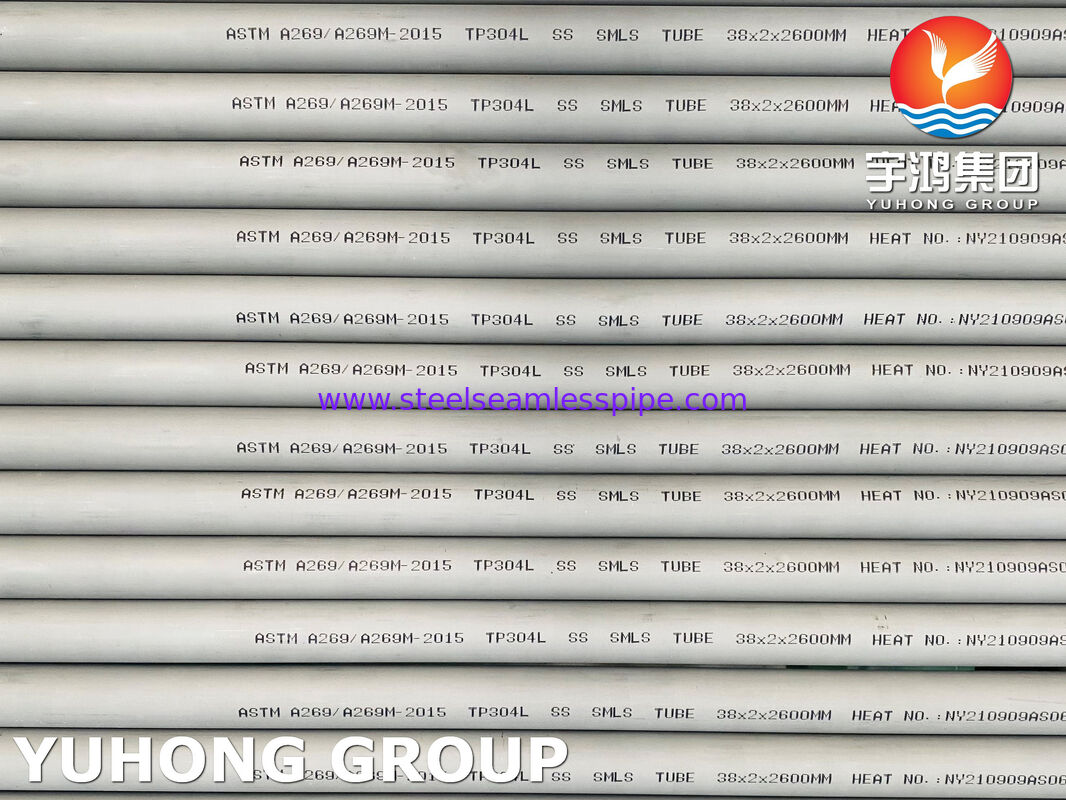

ASTM A269 TP304L / 03Х18Н11 Seamless Stainless Steel Tube for Corrosive Service

Product Overview and Standard Specification

ASTM A269 TP304L stainless steel seamless tubing is a premium-grade, low-carbon austenitic steel tube engineered for superior corrosion resistance in demanding service environments. The "TP" designation represents "Tube and Pipe," while the "L" indicates low carbon content (C ≤ 0.035%), significantly enhancing resistance to intergranular corrosion, particularly after welding.

This product is manufactured in strict compliance with the latest ASTM A269/A269M-24 standard - the Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service. This specification serves as the primary standard for stainless steel tubing used in general corrosive and high/low-temperature service across critical industries.

The Russian grade 03Х18Н11 is a direct equivalent, sharing nearly identical chemical and mechanical properties, making this tubing a versatile choice for global projects.

Key Standard Features:

- Scope: Covers nominal-wall-thickness, seamless and welded tubing for general corrosion-resisting and low- or high-temperature service

- Manufacturing: All tubing is supplied in the heat-treated (solution annealed) condition to ensure optimal corrosion resistance and mechanical properties

- Testing: Every tube undergoes mandatory non-destructive electric testing or hydrostatic testing, with additional tests like flattening, flaring, and hardness tests performed as required

Material and Chemical Composition

TP304L is an 18-8 chromium-nickel stainless steel. Its low carbon content minimizes the precipitation of chromium carbides during welding, preserving the material's inherent corrosion resistance in the heat-affected zone.

The chemical composition conforms to the stringent requirements of ASTM A269 and related standards such as ASTM A959. The typical composition range is as follows:

Table 1: Chemical Composition of ASTM A269 TP304L (Weight %)

| Element |

Content |

| Carbon (C) |

≤ 0.035 % |

| Manganese (Mn) |

≤ 2.00 % |

| Phosphorus (P) |

≤ 0.045 % |

| Sulfur (S) |

≤ 0.030 % |

| Silicon (Si) |

≤ 1.00 % |

| Chromium (Cr) |

18.00 - 20.00 % |

| Nickel (Ni) |

8.00 - 12.00 % |

| Iron (Fe) |

Balance |

Mechanical and Physical Properties

In the annealed condition, ASTM A269 TP304L seamless tubing offers an excellent balance of strength and ductility. The following table outlines the key mechanical properties as per the standard and common industry data.

Table 2: Mechanical Properties of ASTM A269 TP304L Seamless Tube

| Property |

Standard Requirement / Typical Value |

Notes |

| Tensile Strength |

≥ 485 MPa (70 ksi) |

Minimum required value |

| Yield Strength (0.2% Offset) |

≥ 170 MPa (25 ksi) |

For annealed condition |

| Elongation |

≥ 40 % |

A measure of ductility |

| Hardness (Maximum) |

Rockwell B90 |

Ensures good machinability and formability |

| Heat Treatment |

Solution Annealed |

Heated to ≥1040°C and rapidly cooled for optimal properties |

Product Applications

Due to its reliable performance, hygiene, and ease of fabrication, ASTM A269 TP304L seamless tubing is specified for a wide range of critical applications:

- Chemical & Petrochemical Processing: Instrumentation lines, sample lines, and process piping for corrosive fluids

- Pharmaceutical & Food & Beverage: Sanitary tubing systems, process lines, and utility piping where cleanliness and corrosion resistance are paramount

- Oil & Gas: Control lines, instrument tubing, and hydraulic lines

- Heat Exchangers & Condensers: Tubing for shell-and-tube heat exchangers

- Marine and Shipbuilding: Tubing for various marine systems

- General Mechanical and Architectural Engineering: For applications requiring precise dimensions and a good surface finish

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!