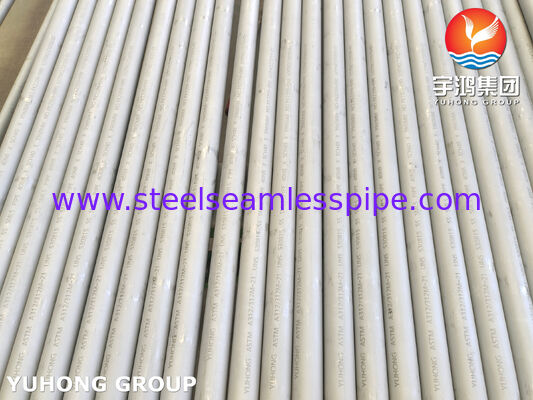

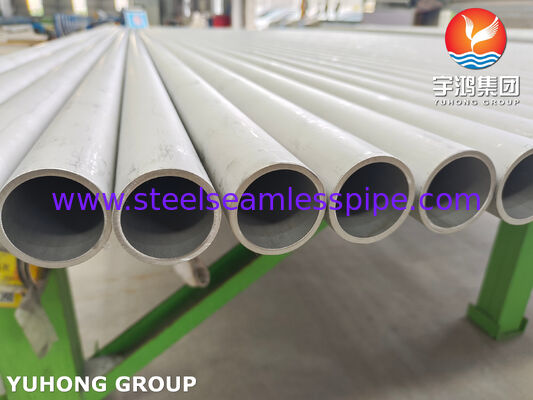

ASTM A312 S30815 / 253MA / EN 1.4835 Stainless Steel Seamless Pipe

Product Introduction & Overview

The ASTM A312 S30815 Seamless Pipe, commonly known as 253MA or EN 1.4835, is a premium-grade, heat-resistant austenitic stainless steel pipe engineered for extreme high-temperature service. This alloy provides a cost-effective solution that bridges the performance gap between standard stainless steels and expensive nickel-based alloys.

This specialized alloy is micro-alloyed with Nitrogen (N) and rare earth elements (Cerium), which are fundamental to its superior performance characteristics. Nitrogen enhances creep strength and stabilizes the austenitic structure, while cerium dramatically improves oxidation resistance. As a result, 253MA seamless pipes deliver an exceptional combination of very high oxidation resistance, excellent creep rupture strength, and good corrosion resistance in most gaseous atmospheres at elevated temperatures.

These pipes are designed for use in pressurized applications up to 900°C (1652°F) and for non-pressurized components at temperatures as high as 1150°C (2102°F).

Standard Specifications & Compliance

This seamless pipe is manufactured in full compliance with international standard ASTM A312/A312M, which specifies requirements for seamless, welded, and heavily cold-worked austenitic stainless steel pipes. It conforms to the specific grade S30815 within this standard.

- Primary Standard: ASTM A312 / ASME SA312 (Grade S30815)

- Material Standard: ASTM A240 / ASME SA-240 (for plate/sheet), ASTM A276

- Forging/Fitting Standard: ASTM A182 / ASME SA-182

- Unified Numbering System (UNS): S30815

- European Standard (DIN/EN): 1.4835

- Common Commercial Designation: 253MA

Material & Key Characteristics

253MA is a "lean" austenitic stainless steel with a balanced chemical composition that delivers outstanding high-temperature properties despite its relatively lower chromium and nickel content compared to other heat-resistant alloys.

- Exceptional High-Temperature Strength: Maintains high tensile and yield strength, as well as excellent creep and rupture strength, at temperatures from 850°C to 1100°C

- Superior Oxidation Resistance: The synergistic effect of silicon and rare earth elements forms a stable, protective oxide layer, providing scaling resistance up to 1150°C

- Good Fabricability: Offers satisfactory weldability using all common methods (without pre- or post-weld heat treatment), good formability, and adequate machinability

- Cost-Effective Performance: Provides performance comparable to high-alloy steels and nickel-base alloys in many applications, offering significant economic advantages

Chemical Composition (Weight %)

The following table details the alloying elements that define the S30815/253MA material's properties.

| Element |

Composition Range (%) |

Key Role |

| Carbon (C) |

0.05 - 0.10 |

Strengthener; enhances high-temperature strength |

| Manganese (Mn) |

0.80 |

Aids in deoxidation during steelmaking |

| Phosphorus (P) |

0.040 |

Impurity element (controlled at low levels) |

| Sulfur (S) |

0.030 |

Impurity element (controlled at low levels) |

| Silicon (Si) |

1.40 - 2.00 |

Improves oxidation and scaling resistance |

| Chromium (Cr) |

20.00 - 22.00 |

Provides basic corrosion & oxidation resistance |

| Nickel (Ni) |

10.00 - 12.00 |

Stabilizes the austenitic structure for toughness |

| Nitrogen (N) |

0.14 - 0.20 |

Crucial: Greatly improves creep strength and solid solution strengthening |

| Cerium (Ce) |

0.03 - 0.08 |

Crucial: Rare earth element that dramatically improves adhesion of the protective oxide scale |

Mechanical & Physical Properties

The pipes are supplied in a solution-annealed condition (typically 1050°C (1920°F), followed by rapid cooling) to achieve optimal properties.

| Property |

Metric Unit |

Imperial Unit |

| Tensile Strength (Rm) |

600 MPa |

87 ksi |

| Yield Strength (Rp0.2) |

310 MPa |

45 ksi |

| Elongation (A) |

35% |

35% |

Important Note on High-Temperature Performance: The key advantage of 253MA is its retained strength at high temperatures. Its short-term tensile strength at elevated temperatures can be over 20% higher than that of common stainless steels like 304 or 310S.

Primary Application Scenarios

ASTM A312 S30815 seamless pipes are specified for demanding high-temperature environments across heavy industry, where reliability under thermal cycling and corrosive atmospheres is critical.

- Metallurgy & Steel Production: Components in sintering plants, blast furnaces, melting furnaces, continuous casting equipment, rolling mill heating furnaces, and heat treatment furnaces

- Mineral Processing & Cement Manufacturing: Equipment for calcining, roasting, and high-temperature material handling in cement kilns and mineral processing plants

- Thermal Processing: Radiant tubes, muffles, retorts, and other furnace accessories and internals exposed to temperatures above 900°C

- Power Generation & Chemical Processing: High-temperature ducting, piping, and supports in waste incineration, heat recovery, and catalytic cracking systems

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!