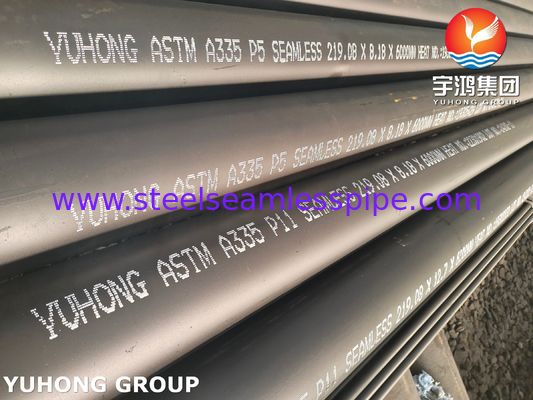

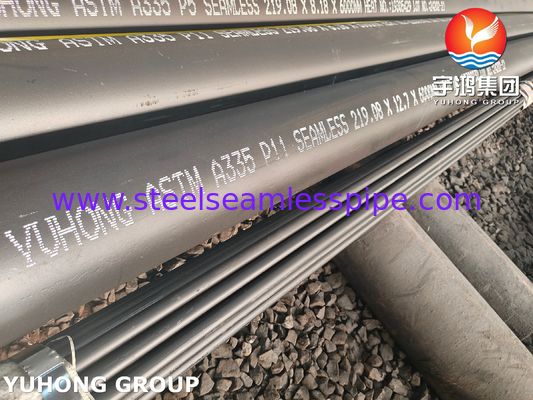

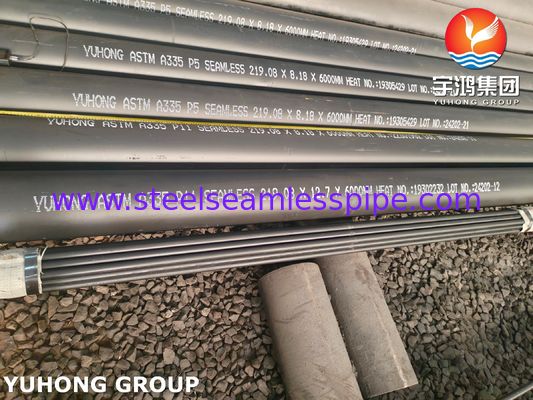

A335 P11 Ferritic Alloy-Steel Seamless Pipe, Hot-Finished and Good Weldability, For Steam Lines And Boilers

What is ASTM A335 P11 pipe?

P11 is a low-alloy heat-resistant steel, belonging to alloy steel, of which the most prominent advantage is one hundred percent recyclable, according to the production process, P11 can be divided into two kinds of hot-rolled seamless steel pipe and cold-rolled seamless steel pipe, of which cold-rolled pipe is divided into two kinds of round pipe and profiled pipe.

The production process of hot rolled seamless steel pipe is round billet, heating, piercing, three-roll diagonal zigzag, continuous zigzag or extrusion, stripping, stemming, cooling, billet, straightening, hydrostatic test, marking, storage.

Cold rolled seamless steel pipe making process is round billet, heating, piercing, beating, annealing, pickling, oiling, multi-pass cold drawing, billet pipe, heat treatment, straightening, water pressure test, marking, storage,

Chemical composition of ASTM A335 P11

| C, % |

S, % |

Si, % |

Mn, % |

P, % |

Cr, % |

Mo, % |

| 0.015 Maximum |

0.025 Maximum |

0.50 Maximum |

0.30-0.60 |

0.025 Maximum |

4.00-6.00 |

0.45-0.65 |

Mechanical properties of ASTM A335 P11

| Tensile Strength, in MPa |

Yield Strength, in MPa |

Elongation, % |

| 415 minimum |

205 minimum |

30 minimum

|

Equivalent Standard of ASTM A335 P11

| ASME |

ASTM |

Tube Equivalent |

JIS G 3458 |

BS |

UNS |

NK |

ABS |

| SA 335 P11 |

A335 P11 |

SA 213 T11 |

STPA 23 |

3604 P1 621 |

K11597 |

KSTPA 23 |

ABS 11 |

Heat treatment

Tubes of ASTM A335 P11 may be cold drawn or hot rolled. Each tube should be re-tempered - fully or isothermally annealed, normalised and tempered at a temperature of not less than 650°C.

Along with dimensional and visual inspection, each length of ASTM A335 P11 pipe should be hydrostatically tested. Longitudinal or transverse tension tests, flattening tests or bending tests shall be carried out on each hot number of the furnace. When specified by the buyer, one of the alternative non-destructive tests may be carried out: ultrasonic testing, eddy current testing or solder leakage testing. Hardness testing is not necessary.

| Grade Comparison |

Type of Heat Treatment |

Normalizing heat treatment Temperature F [C] |

Subcritical Tempering/ Annealing

material Temperature F

[C] |

| A335 P5 (b,c) |

Isothermal or Full Annealing |

|

|

| |

Temper and Normalize |

|

1250 F [675] |

| |

Subcritical Annealing (A335 P5c only) |

|

1325 - 1375 F [715 - 745] |

| A335 P9 |

Isothermal or Full Annealing |

|

|

| |

Temper and Normalize |

|

1250 F [675 C] |

| A335 P11 |

Isothermal or Full Annealing |

|

|

| |

Temper and Normalize |

|

1200 F [650 C] |

| A335 P22 |

Isothermal or Full Annealing |

|

|

| |

Temper and Normalize |

|

1250 F [675 C] |

| A335 P91 |

Temper and Normalize |

1900 to 1975 F [1040 to 1080 C] |

1350-1470 F [730 to 800 C] |

| |

Temper and Quench |

1900 to 1975 F [1040 to 1080 C] |

1350-1470 F [730 to 800 C] |

Application

- Boiler

- Nuclear reactors

- Spacecraft

- Heat exchanger

- Overheater

- Economizer

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!