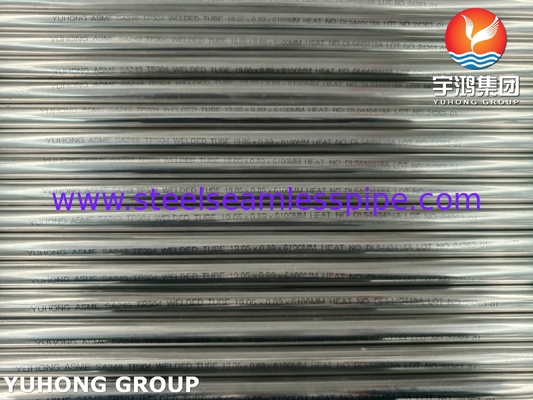

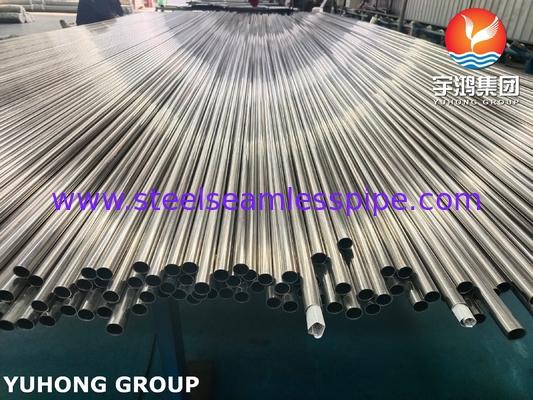

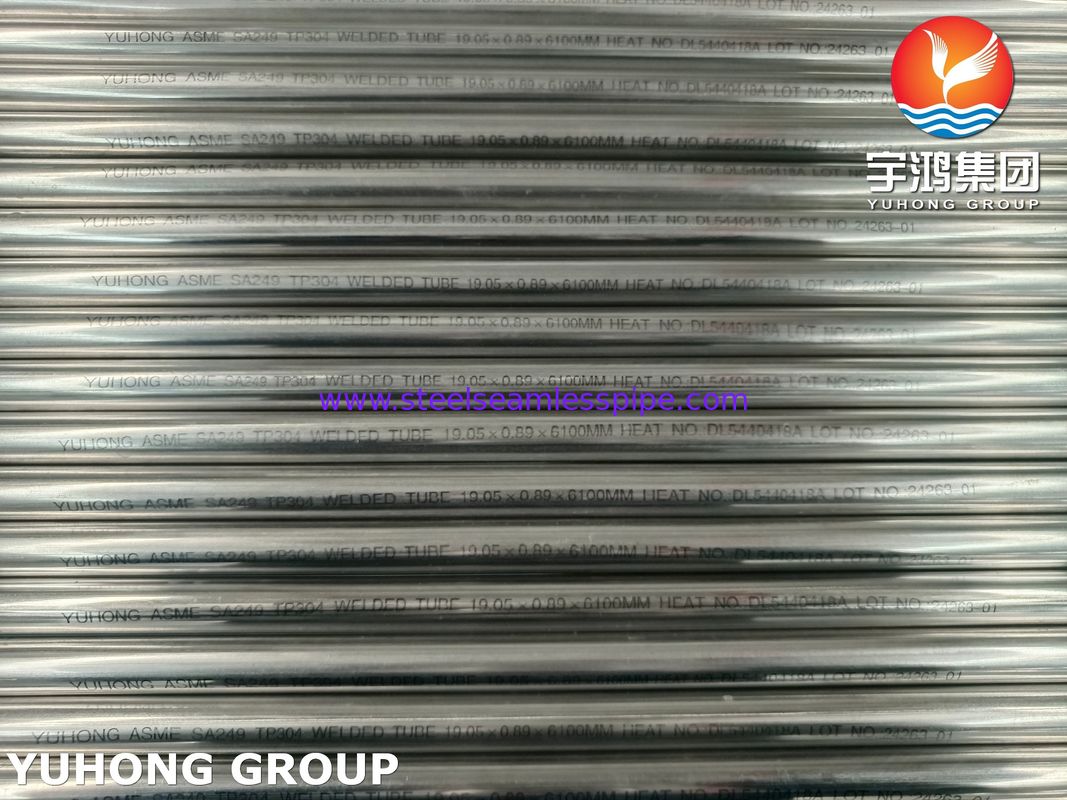

ASTM A249 TP304 Stainless Steel Welded Heat Exchanger Tube Bright Annealed

ASTM A249 is a standard developed by the American Society for Testing and Materials (ASTM) specifically to specify technical requirements for welding austenitic stainless steel tubes and ferritic alloy steel tubes for boilers, superheaters, and heat exchangers. TP304, as a key material grade under this standard, has unique chemical composition and performance. The main chemical components of ASTM A249 TP304 stainless steel welded heat exchanger tube include: carbon (C) ≤ 0.08 (but TP304L, as an ultra-low carbon version, has a carbon content not exceeding 0.03%), silicon (Si) ≤ 1.00, manganese (Mn) ≤ 2.0, phosphorus (P) ≤ 0.045, sulfur (S) ≤ 0.030, nickel (Ni) 8.00-12.00, chromium (Cr) 18.00-20.00. These chemical components ensure that TP304 welded tubes have excellent corrosion resistance and good formability.

ASTM A249 Stainless Steel Welded Heat Exchanger Tube Chemical Composition

| SS GRADE |

ASTM A249/SA 249 CHEMICAL COMPOSITION % MAXIMUM |

| C |

MN |

P |

S |

SI |

CR |

NI |

| TP304 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

18.0-20.0 |

8.0-11.0 |

| TP304L |

0.030 |

2.00 |

0.045 |

0.030 |

1.00 |

18.0-20.0 |

8.0-12.0 |

The manufacturing process of ASTM A249 TP304 stainless steel welded heat exhcanger tubes strictly adheres to relevant standards, including material inspection, tube blank preparation, welding, heat treatment, non-destructive testing, and final inspection. Among them, welding process is one of the key, using advanced TIG (tungsten inert gas welding) or MIG (metal inert gas welding) technology to ensure high weld quality and few defects. In addition, the heat treatment process can further eliminate welding residual stress, improve the mechanical properties and corrosion resistance of the pipeline. In terms of quality control, manufacturers need to strictly screen raw materials and monitor each link in the production process in real time to ensure stable and reliable product quality.

The high proportion of chromium and nickel elements makes TP304 stainless steel welded heat exchanger tube have excellent corrosion resistance, which can resist the erosion of various corrosive media; Under high temperature conditions, TP304 stainless steel welded heat exchanger tube can still maintain high strength and toughness, making them suitable for working environments with high temperature and high pressure; At the same time, TP304 stainless steel welded heat exchanger tube has good antioxidant properties and can maintain stable performance within a certain high temperature range; TP304 stainless steel welded heat exchanger tube is easy to process and form, making it convenient to manufacture pipeline systems in various shapes and sizes.

ASTM A249 TP304 stainless steel welded heat exchanger tubes shall be made from flat-rolled steel by an automatic welding process with no addition of filler metal.

Subsequent to welding and prior to final heat treatment, the tubes shall be cold worked either in both weld and base metal or in weld metal only. The method of cold working may be specified by the purchaser. When cold drawn, the purchaser may specify the minimum amount of reduction in

cross-sectional area or wall thickness, or both.

Heavily cold worked (HCW) tubes shall be made by applying cold working of not less than 35 % reduction in both wall and weld to a welded tube prior to the final anneal. No filler metal shall be used in the making of the weld. Prior to cold working, the weld shall be 100 % radiographically inspected in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section VIII, Division 1, latest revision, Paragraph UW 51.

ASTM A249 Stainless Steel Welded Heat Exchanger Tube Application

- Oil and gas industry: TP304 stainless steel welded heat exchanger tube is commonly used in key areas such as oil well casings, gathering pipelines, and refinery process pipelines during the extraction, transportation, and processing of oil and gas. Its corrosion resistance and high temperature strength ensure the safe and efficient transportation of oil and gas resources.

- Chemical industry: TP304 stainless steel welded heat exchanger tube is used to manufacture various reactors, heat exchangers, storage tanks, and pipelines for transporting corrosive media. Its excellent corrosion resistance enables it to resist the erosion of various chemical substances, ensuring the stability of the production process and the purity of the product.

- Pharmaceutical industry: The pharmaceutical industry has extremely high requirements for equipment cleanliness and corrosion resistance. TP304 stainless steel welded heat exchanger tube is widely used in the manufacturing of pharmaceutical equipment, such as reactors, storage tanks, and conveying pipelines, due to its non-toxic, odorless, easy to clean and maintain characteristics.

- Food processing industry: TP304 stainless steel welded heat exchanger tube is used in the manufacturing and transportation of pipeline systems for food raw materials and products in the food processing and beverage production processes. Its material properties ensure the safety and hygiene of food during contact with pipelines.

-

Power industry: TP304 stainless steel welded heat exchanger tube is commonly used in the manufacturing of equipment such as boilers, superheaters, heat exchangers, and condensers. Its high temperature strength and corrosion resistance enable it to withstand working environments of high temperature and high pressure, ensuring the stable operation of power generation equipment.

- Paper industry: TP304 stainless steel welded heat exchanger tube is used to transport media such as pulp, chemicals, and wastewater. Its corrosion resistance and wear resistance enable it to adapt to the special working environment of the paper industry.

- Water treatment industry: TP304 stainless steel welded heat exchanger tube is used to manufacture various water treatment equipment, such as filters, reactors, and pipelines. Its corrosion resistance enables it to withstand the erosion of chemicals and microorganisms in water.

- Construction and decoration industry: TP304 stainless steel welded heat exchanger tube is also commonly used in the construction and decoration fields, such as making stainless steel railings, handrails, doors and windows, etc. Its beautiful appearance and excellent corrosion resistance make it the preferred material in the construction and decoration industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!