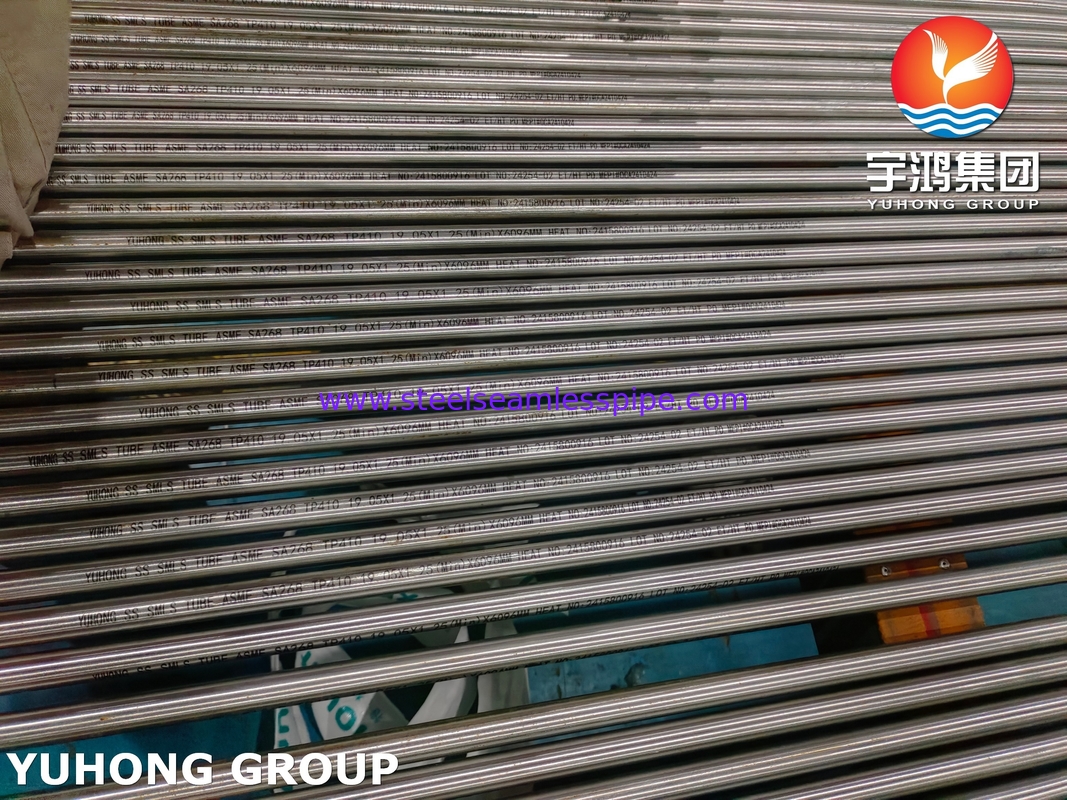

ASTM A268 TP410 Stainless Steel Seamless Tube Bright Annealed Heat Exchanger Tube

ASTM A268 is a standard developed by the American Society for Testing and Materials, titled "Standard Specification for Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service", which covers seamless and welded tubes primarily used for general service purposes in medium or high temperature corrosive environments.

TP410 stainless steel seamless tubes can achieve a wide range of mechanical properties from high toughness to high hardness through quenching (oil cooling or air cooling) and tempering, thereby possessing excellent heat treatable properties, which is the most significant feature of TP410 stainless steel tubes. On the other hand, the weldability of TP410 stainless steel seamless tubes is generally poor. Improper welding or post weld heat treatment can easily produce a hard and brittle martensitic structure, increasing the risk of cracking in the welding area. Pre weld preheating and post weld treatment are usually required, especially for TP410 stainless steel seamless tubes with thicker walls.

ASTM A268 TP410 Stainless Steel Heat Exchanger Tube Properties

1. like other stainless steel materials, TP410 stainless steel heat exchanger tube has a very good strength, and the strength is still very good, so it will be more laborious when processing, but the performance is still very good when using.

2. TP410 stainless steel heat exchanger tube has a very good characteristics, that is, its weight is relatively light, so it absorbs energy than other metal materials to be lighter, ety performance is very good, so it is used in the automotive transportation industry is relatively wide, this time its body-centered cubic crystal structure plays a very good performance.

3. TP410 stainless steel heat exchanger tube also has a very special characteristics, that is, its composition does not contain nickel, but also contains a small amount of Ti, Mo, Nb and other elements, so the thermal conductivity of this material is very good, at the same time, it also has a very good expansion coefficient and oxidation resistance. Sometimes it can also resist the erosion of some corrosive substances, so we can see that this material is used in parts that are resistant to atmospheric, water vapor and other substances.

4. the most important thing is that this stainless steel rust resistance is very not coarse, in the process of use it can adapt to the external environment, temperature and humidity and other external environment can also be very good, even in the environment is more harsh place it can be used more normal, and long-term use of the basic performance will not be too much affected.

ASTM A268 TP410 Stainless Steel Heat Exchanger Tube Chemical Composition

| Element |

Carbon |

Mn |

Si |

P |

S |

Cr |

MO |

Ni |

N |

| TP410 |

minimum value |

- |

- |

- |

- |

- |

11.5 |

- |

- |

- |

| maximum value |

0.15 |

1.0 |

1.0 |

0.040 |

0.030 |

13.5 |

0.75 |

- |

ASTM A268 TP410 Stainless Steel Heat Exchanger Tube Equivalent Material

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

KS |

| TP410 |

1.4006 |

S41000 |

SUS410 |

STS410 |

ASTM A268 TP 410 Stainless Steel Heat Exchanger Tube Mechanical Properties

| Tensile Stress, Mpa |

Yield Stress, MPa |

Elongation, % |

Hardness, HB |

| 415 minimum |

205 minimum |

20 minimum |

207 maximum |

ASTM A268 TP410 Stainless Steel Heat Exchanger Tube Application areas

- Automotive industry: In the automotive industry, ASTM A268 TP410 stainless steel seamless tubes can be used as fuel pipes, oil pipes, hydraulic pipes, and exhaust system components. At the same time, attention should be paid to the corrosion of pipes by high-temperature oxidation and condensation.

-

Petrochemicals and Energy: ASTM A268 TP410 stainless steel seamless tubes can be used for instrument pipes, heat tracing pipes, boiler feedwater pipes, and heat exchanger pipes in mild corrosive environments, but attention should also be paid to water quality and chloride content.

-

Mechanical manufacturing: In terms of mechanical manufacturing, ASTM A268 TP410 stainless steel seamless tubes can be used as hydraulic and pneumatic system pipelines, bearing sleeves, wear-resistant components (after heat treatment), and shafts.

-

General Engineering: ASTM A268 TP410 can be used in general industrial engineering as structural components, supports, and fasteners that require moderate corrosion resistance and certain strength.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!