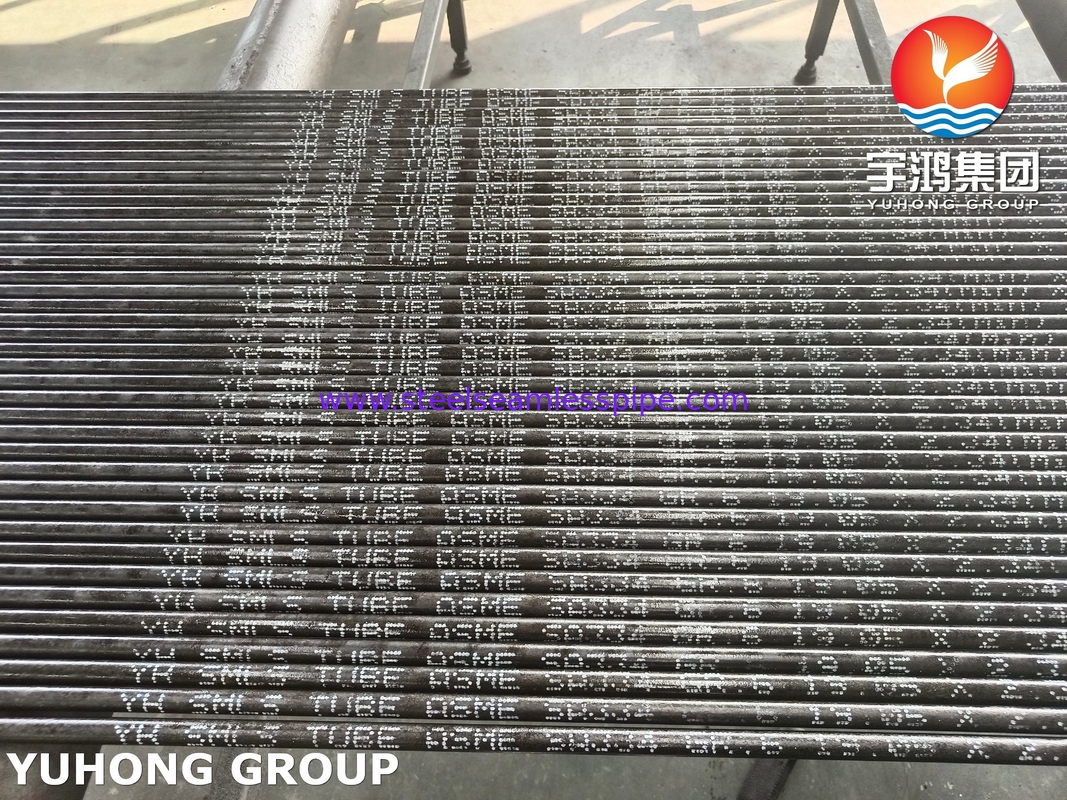

ASME SA334 Gr.6 Carbon Steel Seamless Tube for Heat Exchanger, Oil and Gas Industry

ASTM A334 Grade 6 is a specific type of low-temperature carbon steel tubing are manufactured from a combination of carbon steel and certain alloying elements, which can include manganese, silicon, and small amounts of other materials. The precise composition of the tubes ensures that they can maintain their mechanical properties even in harsh environments, particularly for transporting fluids at low temperatures, commonly used in oil/gas, petrochemical, and power generation industries.The manufacturing process may involve both seamless and welded methods, with seamless tubes generally preferred for their superior structural integrity.

Key Characteristics of ASME SA334 Grade 6 Carbon Steel Seamless Tube

1. Low-Temperature Resistance: The primary advantage of A334 Grade 6 tubes is their ability to withstand extremely low temperatures without becoming brittle. This characteristic is crucial in industries such as oil and gas, where materials are often exposed to frigid conditions.

2. Versatility: These tubes are not only used in various industries but can also be adapted to different applications, making them versatile components for engineers and designers.

3. Strength and Durability: With a minimum yield strength of approximately 35,000 psi, A334 Grade 6 tubes can handle significant stress, making them suitable for high-pressure applications.

4. Weldability: The chemistry of A334 Grade 6 allows for good weldability, which is a critical feature in manufacturing and assembly processes.

Chemical Composition for ASTM A334 Grade 6 Carbon Steel Seamless Tubes

| Grade |

Mfg. Process |

Chemical composition(%) |

| C |

Si |

Mn |

P |

S |

Ni |

Others |

| Grade 1 |

S, E, AT |

0.30Max |

- |

0.40~1.06 |

0.05Max |

0.60Max |

- |

(STBL450) |

| Grade 3 |

S, E, AT |

0.19Max |

0.18~0.37 |

0.31~0.64 |

0.05Max |

0.050Max |

3.18-3.82 |

- |

| Grade 6 |

S, E, AT |

0.30Max |

0.10Max |

0.29~1.06 |

0.048Max |

0.058Max |

- |

- |

| Grade 7 |

S, E, AT |

0.19Max |

0.13~0.32 |

0.90Max |

0.04Max |

0.050Max |

2.03~2.57 |

(STBL690) |

| Grade 8 |

S, E, AT |

0.18Max |

0.13~0.32 |

0.90Max |

0.045Max |

0.045Max |

8.40~9.60 |

(Cu 0.75~1.25) |

| Grade 9 |

S, E, AT |

0.20Max |

- |

0.40~1.06 |

0.045Max |

0.50Max |

1.60~2.24 |

- |

Mechanical Properties for ASTM A334 Grade 6 Carbon Steel Seamless Tubes

| Grade |

Tensile Test MPa or N/mm2 |

Remaks

(Similar to JIS) |

| Min Yield point |

Tensile Strength |

| Gr. 1 |

205 |

380Min |

Impact Test(J)

2V 18 |

| Gr. 3 |

240 |

450Min |

2V 18 |

| Gr. 6 |

240 |

415Min |

2V 18 |

| Gr. 7 |

240 |

450Min |

2V 18 |

| Gr. 8 |

520 |

690Min |

2V 18 |

| Gr. 9 |

315 |

435Min |

2V 18 |

ASTM A334 / ASME SA334 GR.6 tubes Hydrostatic or NDT test Each A334 GR.6 tube shall be subjected to the nondestructive electric test or the hydrostatic test. The type of test to be used shall be at the option of the manufacturer, unless otherwise specified in the purchase order.

1. Hydrostatic Testing

- Purpose: Hydrostatic testing is designed to check the strength and leak-tightness of the tubes.

- Process: The tube is filled with water and subjected to a specified internal pressure greater than the normal operating pressure. This pressure is held for a designated period to allow for a thorough examination.

- Outcome: If there are no leaks and the tube maintains its integrity under pressure, it passes the test. This method provides a clear indication of the tube's durability and ability to withstand operational conditions.

2. Nondestructive Electric Testing (NDT)

- Purpose: Nondestructive testing is utilized to detect flaws or inconsistencies without causing permanent damage to the tube.

- Process: This test often involves methods such as eddy current testing, ultrasonic testing, or magnetic particle testing. The chosen technique will depend on the specific requirements and the manufacturer's capabilities.

- Outcome: NDT ensures that any defects, such as cracks or inclusions, are identified without compromising the tube’s integrity. This method is essential for maintaining quality and safety standards.

Other available materials

| Carbon |

Chromiun |

Low Temperature |

Stainless Steel |

Duplex |

Copper& Bronze |

Titanium |

Ni-Alloy |

| SA178-A |

SA213-T1 |

SA333-Gr.1 |

SA213 |

TP316L |

A789-S31803 |

SB111-C70600 |

SB338-GR.1 |

SB163 |

NO2200 |

| SA178-C |

SA213-T11 |

SA333-Gr.3 |

SA249 |

TP316H |

A789-S32205 |

SB111-C71500 |

SB338-GR.2 |

SB167 |

NO2201 |

| SA179 |

SA213-T12 |

SA333-Gr.6 |

SA268 |

TP316Ti |

A789-S32750 |

SB111-C71640 |

SB338-GR.5 |

SB444 |

NO8020 |

| SA192 |

SA213-T22 |

SA333-Gr.7 |

SA269 |

TP316LN |

A789-S32760 |

SB111-C68700 |

SB338-GR.7 |

SB514 |

NO6022 |

| SA209-T1 |

SA213-T5 |

SA333-Gr.8 |

SA376 |

TP321 |

A789-S32707 |

SB111-C44300 |

SB338-GR.9 |

SB619 |

N10276 |

| SA209-T1a |

SA213-T9 |

SA334-Gr.1 |

TP304 |

TP321H |

A789-S32304 |

|

SB338-GR.12 |

SB622 |

NO4400 |

| SA209-T1b |

SA213-T91 |

SA334-Gr.3 |

TP304L |

TP347 |

A789-S31500 |

|

|

SB626 |

NO6600 |

| SA210-A1 |

|

SA334-Gr.6 |

TP304H |

TP347H |

S31254 |

|

|

SB674 |

NO6601 |

| SA210-C |

|

SA334-Gr.7 |

TP304N |

TP405 |

254MA |

|

|

SB677 |

NO6625 |

| SA214 |

|

SA334-Gr.8 |

TP310H |

TP409 |

17-4PH |

|

|

SB704 |

NO690 |

| SA513 MT 1010 |

|

|

TP310S |

TP410 |

17-7PH |

|

|

SB705 |

NO8800 |

| SA513 MT 1015 |

|

|

TP309S |

TP430 |

15-7PH |

|

|

N1001 |

NO8810 |

| SA513 MT 1020 |

|

|

TP317 |

TP439 |

|

|

|

N10665 |

NO8811 |

| |

|

|

TP317L |

TP444 |

|

|

|

N10675 |

NO8825 |

| |

|

|

TP348 |

TP446 |

|

|

|

TP904L |

|

| |

|

|

TP347HFG |

|

|

|

|

|

|

Application

- Oil and Gas Pipelines: Used in transporting crude oil and natural gas, especially in colder regions where low-temperature properties are vital.

- Pressure Vessels: Essential for constructing pressure vessels that operate efficiently in low-temperature settings.

- Heat Exchangers: Utilized in heat exchangers where thermal efficiency and durability are paramount.

- Cryogenic Facilities: Applied in systems designed to handle liquefied gases near their boiling points.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!